Ore Control and Reconciliation Sunday November 30

advertisement

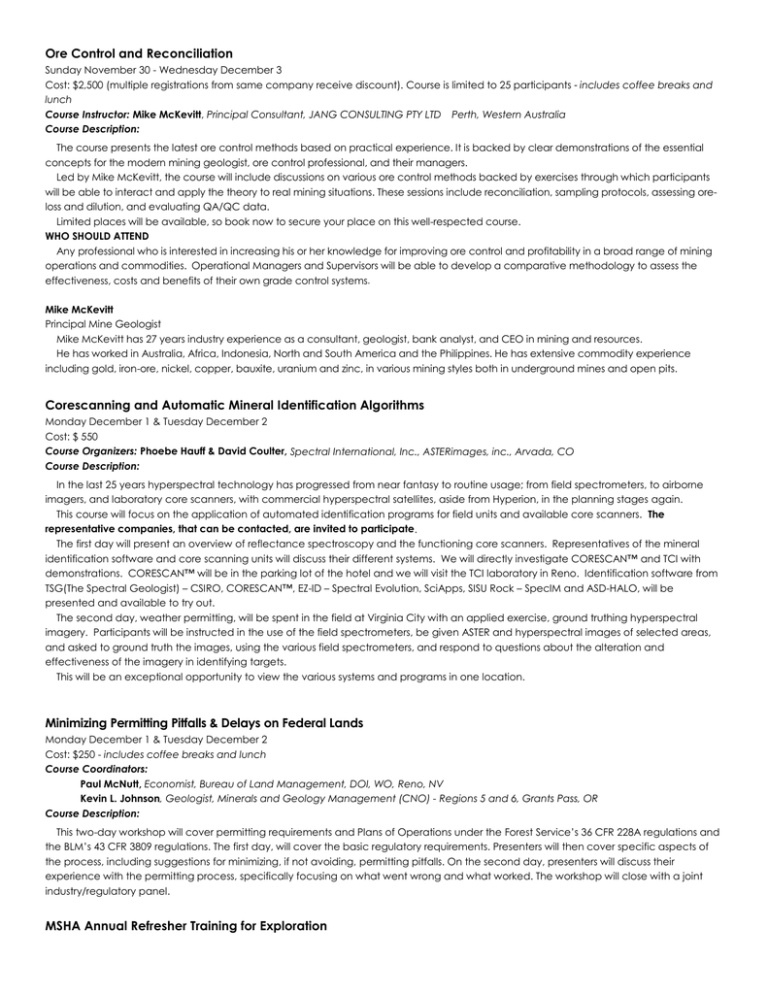

Ore Control and Reconciliation Sunday November 30 - Wednesday December 3 Cost: $2,500 (multiple registrations from same company receive discount). Course is limited to 25 participants - includes coffee breaks and lunch Course Instructor: Mike McKevitt, Principal Consultant, JANG CONSULTING PTY LTD Perth, Western Australia Course Description: The course presents the latest ore control methods based on practical experience. It is backed by clear demonstrations of the essential concepts for the modern mining geologist, ore control professional, and their managers. Led by Mike McKevitt, the course will include discussions on various ore control methods backed by exercises through which participants will be able to interact and apply the theory to real mining situations. These sessions include reconciliation, sampling protocols, assessing oreloss and dilution, and evaluating QA/QC data. Limited places will be available, so book now to secure your place on this well-respected course. WHO SHOULD ATTEND Any professional who is interested in increasing his or her knowledge for improving ore control and profitability in a broad range of mining operations and commodities. Operational Managers and Supervisors will be able to develop a comparative methodology to assess the effectiveness, costs and benefits of their own grade control systems. Mike McKevitt Principal Mine Geologist Mike McKevitt has 27 years industry experience as a consultant, geologist, bank analyst, and CEO in mining and resources. He has worked in Australia, Africa, Indonesia, North and South America and the Philippines. He has extensive commodity experience including gold, iron-ore, nickel, copper, bauxite, uranium and zinc, in various mining styles both in underground mines and open pits. Corescanning and Automatic Mineral Identification Algorithms Monday December 1 & Tuesday December 2 Cost: $ 550 Course Organizers: Phoebe Hauff & David Coulter, Spectral International, Inc., ASTERimages, inc., Arvada, CO Course Description: In the last 25 years hyperspectral technology has progressed from near fantasy to routine usage; from field spectrometers, to airborne imagers, and laboratory core scanners, with commercial hyperspectral satellites, aside from Hyperion, in the planning stages again. This course will focus on the application of automated identification programs for field units and available core scanners. The representative companies, that can be contacted, are invited to participate. The first day will present an overview of reflectance spectroscopy and the functioning core scanners. Representatives of the mineral identification software and core scanning units will discuss their different systems. We will directly investigate CORESCAN™ and TCI with demonstrations. CORESCAN™ will be in the parking lot of the hotel and we will visit the TCI laboratory in Reno. Identification software from TSG(The Spectral Geologist) – CSIRO, CORESCAN™, EZ-ID – Spectral Evolution, SciApps, SISU Rock – SpecIM and ASD-HALO, will be presented and available to try out. The second day, weather permitting, will be spent in the field at Virginia City with an applied exercise, ground truthing hyperspectral imagery. Participants will be instructed in the use of the field spectrometers, be given ASTER and hyperspectral images of selected areas, and asked to ground truth the images, using the various field spectrometers, and respond to questions about the alteration and effectiveness of the imagery in identifying targets. This will be an exceptional opportunity to view the various systems and programs in one location. Minimizing Permitting Pitfalls & Delays on Federal Lands Monday December 1 & Tuesday December 2 Cost: $250 - includes coffee breaks and lunch Course Coordinators: Paul McNutt, Economist, Bureau of Land Management, DOI, WO, Reno, NV Kevin L. Johnson, Geologist, Minerals and Geology Management (CNO) - Regions 5 and 6, Grants Pass, OR Course Description: This two-day workshop will cover permitting requirements and Plans of Operations under the Forest Service’s 36 CFR 228A regulations and the BLM’s 43 CFR 3809 regulations. The first day, will cover the basic regulatory requirements. Presenters will then cover specific aspects of the process, including suggestions for minimizing, if not avoiding, permitting pitfalls. On the second day, presenters will discuss their experience with the permitting process, specifically focusing on what went wrong and what worked. The workshop will close with a joint industry/regulatory panel. MSHA Annual Refresher Training for Exploration Monday December 1 Cost: $ 150 Course Instructors: Michael J. Wegleitner, MS, CSP, CMSP, NREMT, Director, Health & Safety, Hecla Ltd., Coeur d’Alene, ID Darrell Tweidt, Regional Business Development Manager, North America, Boart Longyear Services, Elko, NV Course Description: Refresher training will address health and safety subjects that are relevant to mining operations pertaining to the Exploration aspects of the industry (Rotary, Reverse Circulation and Core Drilling). Subjects include: applicable health and safety requirements, including mandatory health and safety standards; information about the physical and health hazards of chemicals in the miner’s work area, the protective measures a miner can take against these hazards, and the contents of the mine’s HazCom program; transportation controls and communication systems; escape and emergency evacuation plans, firewarning and firefighting; ground conditions and control; traffic patterns and control; working in areas of highwalls; water hazards, pits, and spoil banks; illumination and night work; first aid; electrical hazards; prevention of accidents; health; explosives; and respiratory devices. Mobile equipment (haulage and service trucks, front-end loaders and tractors); maintenance and repair (use of hand tools and welding equipment); material handling; fall prevention and protection; and working around moving objects (machine guarding). Class participants will receive a Certificate of Completion and a MSHA 5000-23. Small Operators - Developing your Property Monday December 1 Cost: $ 275 Course Organizer: Mike Doran, Consultant, Boise, ID Course Description: This course will focus on how a prospector, small operator, Junior-Junior can develop their property to the point where an exploration company will lease or buy the property. Tentative topics to be covered are: Sampling Base exploration, drilling, assaying, mapping, etc. How not to get scammed Preparing a property report Permitting Basic joint venturing How to legitimately package your property Using consultants Backfill Systems for Underground Mines Monday December 1 Cost: $ 275 Course Instructor: David Stone, P.E., Senior Mining Consultant, Golder Associates, Inc., Redmond, WA Course Description: Backfill plays important role in most underground mining operations, where mining companies are challenged to minimize their impact while maximizing returns. A modern mine utilizes backfill to improve worker safety, increase ore recovery, and to help reach their sustainability goals. As industry leaders in paste, backfill and thickened tailings, Golder Associates’ Paste Engineering and Design group has designed over 50 backfill systems and assisted with the construction of over 18 backfill plants. Participants in this course will learn about the selection, design and operation of backfill systems; and will benefit from our presenters’ backgrounds and proven track record in delivering these services to clients operating around the globe. Emphasis will be on the practical aspects of plant operations, systems and procedures, based on our experience in design, construction, commissioning and operation of backfill plants. How to Keep People Awake During Your Presentation Tuesday December 2 Cost: $ 500 Course is limited to 10 participants - one participant per company Course Instructors: Jeffrey Bell, Partner, Gallatin Public Affairs, Spokane, WA Eric Williams, Partner, Gallatin Public Affairs, Spokane, WA Course Description: Gallatin’s presentation training will arm you with a powerful set of skills so that the next time you speak before a group, what you say will be remembered. On-camera presentations simulate real-life scenarios and offer invaluable feedback. You’ll leave with a strong presentation and delivery, and the confidence to make the most of any public speaking opportunity. Each participant should bring a 5-7 minute presentation to the short course. It can be either a presentation you’ve already given, or one you’ll make in the future. Presentations can be in PowerPoint, Prezi, Keynote, or other formats, and strictly verbal presentations are welcome as well. Please bring your own computer, and let AEMA know in advance any audio-visual equipment you may need. Course is limited to 10 participants with one participant per company. Usually priced at approximately $2,500 per student with a maximum of 4 participants, this intensive course is a great value for professionals who present to potential investors, permitting agencies, boards of directors, and public meetings. Fundamentals of Mineral & Metallurgical Processing Tuesday December 2 Cost: $ 275 Course Instructors: EUR ING Dr. Corby G. Anderson QP CENG FIMMM FICHEME, Harrison Western Professor, Kroll Institute for Extractive Metallurgy, George S. Ansell Department of Metallurgical and Materials Engineering, Colorado School of Mines, Denver, CO Dr. Courtney Young, QP, Department Head and Lewis S. Prater Distinguished Professor, Metallurgical & Materials Engineering, Montana Tech, Butte, MT Course Description: This short course is open to anyone wanting to learn about mineral processing and extractive metallurgy operations .It is particularly good as a refresher or introductory course. In this regard, the course begins with simple concepts such as sampling, analysis (mineralogical, chemical and size), material balances and smelter schedules. It then introduces attendees to processing methods and equipment, particularly those utilized in the mining industry (but also the recycling industry as well). Various unit operations are reviewed including comminution (crushing, grinding, screening and classification), mineral separations (flotation, magnetic, gravity and electrostatic), and metal production and purification (hydrometallurgy, pyrometallurgy and electrometallurgy) as well as environmental management (dewatering, tailings disposal, and waste treatment for water, dust and air). Flowsheets of typical operations are reviewed throughout with implications on flowsheet development. Underground Mine Maintenance Facilities – Best Practices Tuesday December 2 Cost: $ 275 Course Instructors: Joe Cline, PE, P.Eng – Engineering Manager, Cementation USA, Inc. Peter Reich, P.Eng, PE – Sr. Mechanical Engineer, Cementation USA, Inc. Course Description: An underground maintenance facility is the major lifeline for mobile fleets in an underground mine. The decision to design, construct and commission an underground maintenance facility is a major undertaking and must take many factors into consideration from the onset. This course will provide an overview of key factors that should be considered, questions that must be answered, and the amount of effort that goes into implementing a major underground mine infrastructure such as this one. Some of the key items that will be discussed include: Best Practices for Facility Layout - Function, Capacity, Access, Equipping, Ventilation, Fire Protection, Lighting, Cranes and other infrastructure. Procurement, Construction, & Commissioning - Identifying and planning for long lead-time procurement, excavation and construction methodologies, optimizing productivity and quality for concrete pours, prefabricated construction or improving field installation efficiency, commissioning checklists. Shotcrete for Underground Support Tuesday December 2 Cost: $ 275 Course Instructor: Lihe (John) Zhang, PhD., P./Eng., Materials Engineer, LZhang Consulting & Testing Ltd., Vancouver, BC, CANADA Course Description: The class will provide basic knowledge and case studies of underground concrete and shotcrete for the site supervisors, nozzleman, engineers and designers. It will cover: 1) Concrete basics: chemistry of cement and concrete, concrete mix design, concrete performance, supplementary cementitious materials and chemical admixtures. 2) Specialty concrete for underground application: self-consolidated concrete (SCC), high performance concrete, and fiber reinforced concrete. 3) Quality control and trouble shooting for concrete: concrete batching, supply, delivery and risk, quality control testing and inspection, curing and protection, strength development, temperature and concrete including temperature effect, hot weather concrete, cold weather concrete, mass concrete construction. 4) Shotcrete basics: ground support, wet-mix process vs. dry-mix process; equipment & system for each process. 5) Fibre reinforced shotcrete: mixing, pumpability, testing and application. 6) Underground shotcrete application – batch, transport, remix, application. 7) Underground shotcrete application - hand nozzlling, robotic sprayer application. 8) Underground shotcrete application – proper use of accelerator. Rio Tinto Kennecott’s Landslide: Best Practices in Communications to Keep Employees Safe and Protect Social License Tuesday Afternoon December 2 Cost: $135 Course Organizer: Heather Barnum, HDR Engineering, Inc., Senior Public Involvement/Public Relations Manager, Salt Lake City, UT Course Description: Learn from Rio Tinto Kennecott how creating a culture of health and safety, as well as keeping employees and stakeholders engaged, are helping them recover from the largest landslide in mining history last April where no one was hurt. This course will share sustainable best practices that can be applied in your organization to improve safety, productivity and your reputation. You’ll hear examples of how employee programs changed personal behaviors and an overall culture that led to an all-time company safety record and 90 percent participation in a cost-saving wellness program. Kennecott will show you how strategic crisis planning and response protected its social license with stakeholders during the landslide and how you can prepare for an emergency – large or small. You will also learn internal communications strategies and tools that will create employee ambassadors who will be safer, invested in the company, and feel informed to share your message internally and externally. Presenters will help you create sustainable programs and tools that reduce barriers of site/facility isolation and technology, and build a central employee community. Topics include: Best practices, tools and techniques in safety, health and wellness, crisis and emergency response, stakeholder engagement, strategic communications and planning and social license to operate that you can apply in your organization. data:text/mce-internal,Courses