Safety

advertisement

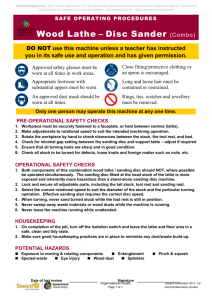

Accidents Happen! You don’t have to encourage them! Personal Behavior No running in lab or classroom. No pushing or shoving in the classroom or lab. No fighting in the classroom or lab. No “horseplay” or fooling around in the classroom or lab. Students are to be “ON TASK” while in the classroom and lab. Clothing Loose, baggy clothing is not to be worn when working on machines with turning parts. They are dangerous. They should be restricted when working in the lab. Roll up loose or long sleeves while working in the lab. Tuck in loose or baggy shirts and blouses. Leave coats, jackets, and sweaters at your seat in the classroom. Use appropriate footwear. Do not wear gloves when using machines with turning parts in the shop. Jewelry Rings, necklaces, chains, bracelets, and watches must be taken off before working on machinery that has turning parts or when it creates a hazard. Hair, Eyes, and Ears Long hair must be restricted (pulled back) in the lab. Must be kept out of your eyes. You must wear safety glasses or safety goggles while in the lab when work is being done. (Glasses should be over the eyes not on the forehead or the back of the neck.) Where noise levels are very loud over long periods of time, ear protection should be worn. Lifting You need to get help to lift heavy things, 1/4 your body weight or more. Do not risk back and abdominal injuries. Long objects should be carried horizontally. The preferred practice is to have a person on each end. Be extremely cautious of raising metal into a vertical position. It can easily come into contact with electrical wiring. Be careful not to drop or set heavy objects on someone’s feet or fingers. They may be yours. Open-toed shoes should not be used in the shop. Shop Do not allow chips, scraps, and other litter to accumulate (gather) on the floor. Wipe up all spilled liquids immediately to help prevent falls. Before operating any piece of machinery in the shop, first learn the safety rules, how the machine works, how to operate the machine, and GET THE INSTRUCTOR’S PERMISSION. Only one person is allowed to run a machine in the shop. Others are to STAY AWAY. Shop (continued) Stay clear of running machines and dangerous areas. Do not allow others to stand near a machine you are using. Report to the instructor any machine or tool that does not function properly or shows need of maintenance. Keep cabinet doors and drawers closed when not in use. All injuries, great or small, must be reported to your instructor. Keep vise handles down when not in use. Tools Keep tools sharp. If treated with disrespect a dull tool can be more dangerous than a sharp tool. If you find a dull tool, get the instructor to take care of it. Always cut away from yourself and others. Always unplug electrical tools when you are working on them, changing an accessory, or when they are not in use. Do not cut the third prong off a three prong plug. Make sure the tool is turned off before plugging it in to the power outlet. Tools (continued) If a power cord is damaged, do not use it. Treat lasers with respect. • • • • Do not look into the beam of a laser. Do not shine the beam into a neighbor’s eye. Do not play games with the beam of the laser. Use the laser only as directed Do not experiment with a tool to find out how it works. Always ask for help or read the instructions. Always treat scissors with respect. Tools (continued) Only use a tool for the purpose it was intended. When finished with a tool, clean it and return it to the proper storage place. Do not use damaged tools. If a tool appears to have a problem, or looks damaged show it to your instructor. Keep hands away from all blades and cutting surfaces. Respect taped safety zones. Tools (continued) Hot glue guns are not toys. Hot glue guns are to be treated with respect. • Do not threaten or brand anyone with them. • Do not stick your fingers in the hot glue. • Give the hot glue plenty of time to cool. • Do not leave the hot glue guns plugged in after you are through with them. Machines – General Only the machine operator is to turn the machine on or off. Turn off all machinery when not in use. Keep your mind on the job and concentrate on running the machine. Do not use any machines when the instructor is not in the lab or class. All adjustments need to be made with the machine turned off. Keep fingers a minimum of 2” away from cutting blades. Machines: Band Saw Before turning on the saw, adjust the upper blade guide so it’s about 1/8”1/4” above the material you’re cutting. Wait for the saw to come to full speed before you start to cut. Wait for the saw to come to a complete stop before leaving the area. Machines: Band Saw If you need to back out of a long cut, turn off the saw and wait for it to come to a complete stop. Do not touch the blade. Guide the material so your hands and fingers are never in line with the cutting teeth. Use a piece of wood to remove scraps from around the blade. Machines: Band Saw Never stand on the right side of the saw. When cutting a curve, cut slowly and do not stop cutting until the curve is completely cut. Make relief cuts before cutting curves. Do not cut material that does not have a flat side on the bottom. Never force the material. Feed the material slowly to allow a smooth, easy cut. Machines: Scroll Saw Check the blade installation, the teeth must point downward. Test the blade tension to see that it is adjusted correctly. When cutting a curve, do not stop cutting until the curve is completely cut. Keep the top guide and pressure foot adjusted to just touching the item being cut. Machines: Drill Press Be sure the bit is sharp, straight and in good condition before using it. The clearance hole in the center of the table must be lined up directly under the cutting tool. Use clamps to hold the material securely on the table. Machines: Drill Press Always remove the chuck key from the chuck before turning on the drill press. Keep hands and fingers away from the area directly under the drill hole in the table. Let the drill press coast to a stop. Never stop it by hand. Machines: Disk and Belt Sanders Always sand material on the down stroke side of the disk sander. Small pieces of material should never be sanded on the power sanders. They could get caught between the table and the sanding belt pulling your fingers into the belt. Replace the sand paper if it becomes damaged or worn. Machines: Disk and Belt Sanders Keep the work moving back and forth to avoid burning the disk sander. Use light pressure while sanding. Keep the work flat against the table while sanding. Do not sand material with wet glue or hot glue on it. Machines: Spindle Sander Keep fingers away from the rotating sanding drum The sanding drum must not be used if it is damaged or worn Small pieces of material should never be sanded on the spindle sander. Keep the table insert in place. Always feed your work against the direction of the sanding drum rotation. It’s no Accident! Machines: Lathe Long sleeves, loose clothing, and hanging items must be removed or tied back before using the lathe. Examine the wood for checks, knots or other defects before you put it on the lathe. The work must be balanced and securely held between centers or mounted on a faceplate. Machines: Lathe The tool rest should be set about 1/4” from the work. Remove the tool rest when sanding and polishing. Use a slow speed to remove material until it is round. When the item is round, higher speeds can be used. Use common sense and caution while turning on the lathe. Machines: Miter Saw The miter saw should not be used for ripping. Material must be held tight against the fence and the table when cutting. Hold the stock within 4-8” of the blade. Angled cuts are more dangerous then square cut, use caution. Machines: Miter Saw Make sure the blade is not touching the material when you turn on the saw. Never cut small stock on the miter saw. Machines: Table Saw On the table saw, always use the proper fence or gauge. Never use the table saw without the safety guard in place. Make all adjustments before turning on the saw. Never clear away scraps when the saw is running. Machines: Table Saw Special setups must be approved by the instructor before making any cuts. Never clear away scrap material from around the blade with your hands. You must get help when sawing large stock on the table saw. Do not stand behind the material or in line with the blade when cutting. Machines: Table Saw A push stick must be used when cutting material which is 4” or skinnier. The blade of the saw should be no more than ¼” above the material being cut. Never reach over the blade on the table saw. Do not cut material shorter than 12”.