Experiment 11 Gearing

advertisement

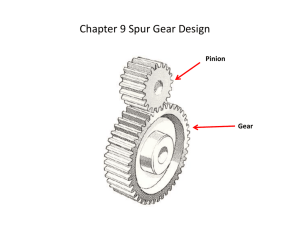

Experiment 11 Gearing Involute Curve Forming of gear http://www.mech.uwa.edu.au/DANotes/gears/meshing/meshing.html#top Nomenclature and definitions Also called base circle Number of teeth Diameter pitch, teeth per length Module Circular pitch Pitch diameter Pressure angle rb r cos Example 1 A gear set consists of a 16 tooth pinion driving a 40 tooth gear. The module is 1. the gear are cut using a pressure angle of 20o. (a) Compute the circular pitch, the center distance, and the radii of the base circles. (b) In mounting these gears, the center distance was incorrectly made 2 mm larger. Compute the new values of the pressure angle and pitch-circle diameters. Sol. (a) Circular pitch p m 3.14mm pitch diameter of pinion and gear d P Nm 16mm, dG Nm 40mm d P dG the center distance is 28mm 2 the base circle is rb ( pinion) 16 / 2 cos 7.52mm rb ( gear ) 40 / 2 cos 18.8mm (b) Designating d P and dG as the new pitch circle diameters, the 2mm increasing in the center distance require that d P dG d 16 30mm and P 2 dG 40 d P 17.14mm dG 42.86mm pressure angle is cos 1 rb ( pinion) 7.52 cos 1 28.66o d P / 2 8.57 Gear train n6 N 2 N3 N 4 n2 N3 N 4 N5 Force analysis Wt Strength of Gear Teeth Max. Stress of a Cantilever beam : 6 F32 h S bt 2 Considering similar triangles AVB and VBC: h .5t t2 or h .5t x 4x 3t 2 F32 F32 F32 F32 2 x S 2 2x 2 x bmY bt b bm 3 3m Lewis form factor AGMA Stress Equations Bending stress F23 Ko Kv K s K H K B , YJ (J) is the geometric factor of bending bmYJ K o = over load factor, K v dynamic factor, K s = size factor(may set to be 1) K H = load distribution factor(approximately 1.2), K B = rim-thickness factor Contact stress C ZE KH ZR F23 K o K v K s d w1b Z I Z E elastic factor, Z R surface condition factor(>1), Z I geometric factor d w1 pitch diameter of pinion Geometric Factor YJ(J) • Surface strength geometric factor ZI(I) mN=1, For spur gear • Elastic coefficient ZE Speed ratio Dynamic coefficient Kv Over load factor Example 2 A steel 20o spur pinion with 20 teeth and a module of 2.5 mm transmits 120 W to a 36 tooth gear. The pinion speed is 100 rpm, the gears are grade 1, 18 mm face width, manufactured to a No. 6 quality standard, and considered to be of open gearing quality installation. Find the AGMA bending and contact stresses and corresponding factors of safety. The allowable strength of the gear tooth is 654Mpa. Contact strength is 1260MPa. Sol. Bending stress Ko Kv K s K H K B F23 , bmYJ YJ (J) =0.327 K o = 1, d p 2.5mm 20 50mm, v d p rpm 3.14 50 100 15700mm / min 52.3 ft / min K v 1.2, K s = 1, K H = 1.2, K B = 1 1.44 F23 = 18 2.5 0.327 60(10)3 H 60(10)3 0.12 but F23 0.46kN dn 50 100 =45MPa safety factor is 14.53 Contact stress C Z E F23 K o K v K s KH ZR d w1b Z I Z E 191, Z R 1.1, K H 1.2 ZI cos t sin t mG =0.1, d w1 50mm 2 mG 1 C 191 460 1.2 0.5432 MPa safety factor=23.7 1.2 1.1 0.05 0.018 0.1 Experiment Rotating speed 1750 rpm, and power 2.5 kW The structure of a simple transmission is shown in previous slide. If the power transfer to lay shaft is 2.5kW at 1750 rpm. The gear and the pinion is made by a material of allowable bending strength 650 Mpa, the allowable contact strength is 1200MPa. If the two reduction ratio 0.75 and 0.5 are required, please select the proper pinion and gear for this system.