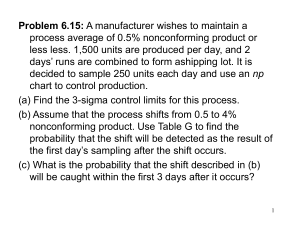

Control Charts for Fraction Nonconforming

advertisement

CHAPTER (7) Attributes Control Charts 1 Introduction • Data that can be classified into one of several categories or classifications is known as attribute data. • Classifications such as conforming and nonconforming are commonly used in quality control. • Another example of attributes data is the count of defects. 2 Control Charts for Fraction Nonconforming • Fraction nonconforming is the ratio of the number of nonconforming items in a population to the total number of items in that population. • Control charts for fraction nonconforming are based on the binomial distribution. 3 Control Charts for Fraction Nonconforming Recall: A quality characteristic follows a binomial distribution if: 1. All trials are independent. 2. Each outcome is either a “success” or “failure”. 3. The probability of success on any trial is given as p. The probability of a failure is 1-p. 4. The probability of a success is constant. 4 Control Charts for Fraction Nonconforming • The binomial distribution with parameters n 0 and 0 < p < 1, is given by n x nx p( x ) p (1 p) x • The mean and variance of the binomial distribution are np 5 np (1 p) 2 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Design of Fraction Nonconforming Chart • Three parameters must be specified 1. The sample size 2. The frequency of sampling 3. The width of the control limits • • 20 Common to base chart on 100% inspection of all process output over a period of time Rational subgroups may also play role in determining sampling frequency Sample size • If p is very small, we should choose n sufficiently large to find at least one nonconforming unit • Otherwise the presence of only one non-conforming in the sample would indicate out-of-control condition (example) • To avoid this, choose n such that the probability of finding at least one nonconforming per sample is at least γ (example) 21 Example • p = 0.01 and n = 8 p(1 p) 0.01(1 0.01) UCL p 3 0.01 3 0.1155 n 8 • If there is one nonconforming in the sample, then p =1/8=0.125 and we conclude that the process is out of control 22 Sample size • The sample size can be determined so that the probability of finding at least one nonconforming unit per sample is at least γ • Example p = 0.01 and γ = 0.95 • Find n such that P(D ≥ 1) ≥ 0.95 • Using Poisson approximation of the binomial with λ =np • From cumulative Poisson table λ must exceed 3.00 np ≥ 3 n ≥ 300 23 Sample size • The sample size can be determined so that a shift of some specified amount, can be detected with a stated level of probability (50% chance of detection). • UCL = pout If is the magnitude of a process shift, then n must satisfy: p(1 p) L n Therefore, 24 2 L n p(1 p) Positive Lower Control Limit • The sample size n, can be chosen so that the lower control limit would be nonzero: p(1 p) LCL p L 0 n and (1 p) n L2 p 25 Interpretation of Points on the Control Chart for Fraction Nonconforming 26 27 Variable Sample Size Variable-Width Control Limits 28 29 30 31 Variable Sample Size Control Limits Based on an Average Sample Size 32 33 Variable Sample Size The Standardized Control Chart 34 35 36 The Opening Characteristic Function and Average Run Length Calculations 37 38 39 40 41 Control Charts for Nonconformities (Defects) Procedures with Constant Sample Size 42 • There are many instances where an item will contain nonconformities but the item itself is not classified as nonconforming. • It is often important to construct control charts for the total number of nonconformities or the average number of nonconformities for a given “area of opportunity”. The inspection unit must be the same for each unit. 43 44 45 46 47 48 49 50 51 52 53 54 Control Charts for Nonconformities (Defects) Procedures with Variable Sample Size 55 56 57 58 59