Control Charts for Attributes

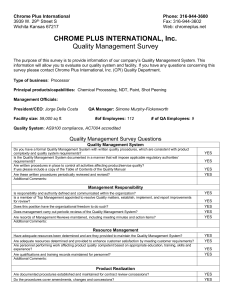

advertisement

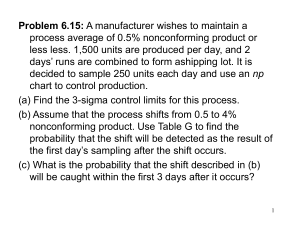

SMU EMIS 7364 NTU TO-570-N Statistical Quality Control Dr. Jerrell T. Stracener, SAE Fellow Control Charts for Attributes Data Updated: 3-17-04 1 Attributes Data Definition - Attributes are quality characteristics for which each inspected item can be classified as conforming or nonconforming to the specification on that quality characteristic Types • Fraction nonconforming • Number nonconforming • Number of nonconformities per unit • Average number of nonconformities per unit 2 Attributes Data • Are best used where subjective characteristics must be checked (presence or absence of nicks, for example) • Tend to emphasize defect reduction as the end goal (vs. variability reduction) defects (count) percentage non-conforming (or percentage) defect per unit • Measurements that depend on counting are called attributes measurements. 3 Fraction Nonconforming Statistical Basis - For a stable process producing identical and independent items with probability p that an item will not conform to spec where D is the number of items nonconforming in a random sample of size n, n x n x b( x ) P(D x ) p q , x 0 , 1 , . . . , n x and D np σ D npq 4 Sample Fraction Nonconforming The sample fraction non-conforming is defined as the ratio of the number of nonconforming in the sample, D, to the sample size n, i.e. D p n ^ and p(1 p) ^ p n 5 Control Chart for Fraction Nonconforming p-chart p(1 p) UCL p 3 n Center Line p p(1 p) LCL p 3 n 6 Control Chart for Fraction Nonconforming p-chart where Di Fraction nonconforming in the pi ith sample for i = 1, 2, . . . , m n ^ 1 m ^ 1 p p m i 1 i mn m D i 1 i 7 Test for Shift in Process Fraction Nonconforming • Hypothesis: H0: p1 = p2 H2: p1 > p2 • Test statistic: ^ Z ^ p1 p 2 ^ 1 1 p1 p n1 n 2 ^ 8 Test for Shift in Process Fraction Nonconforming where f1 p1 n1 ^ f2 p2 n2 ^ ^ ^ n1 p1 n 2 p 2 p n1 n 2 ^ • Decision rule: reject H0 if Z > Z; otherwise accept H0 9 The p-chart - instructions 1. Obtain a series of samples of some appropriate size. Convenient sample sizes are 50 and 100. The ‘sample’ may actually be the complete lot if the entire lot has been checked. Have 20 or more groups if possible, but not less than 10 groups. 2. Count the number of defective units (warped, undersize, oversize, or whatever the characteristics may be in which you are interested). Calculate the value of p for each sample. 10 The p-chart - instructions 3. Calculate p (the average percentage defective). This is the centerline for the p-chart. 4. Calculate upper and lower control limits for the p-chart. 11 Uses of a p-chart • Characteristics on which it is difficult or impractical to obtain variables measurement. • Studies of defects produced by machines or operators which are directly under the machine operators control. • Direct studies of the amount of dropouts, shrinkage, or scrap at specific operations 12 Uses of a p-chart - continued • Can cover all defects and all characteristics, • Can be a valuable capability study in itself • Will also provide a good measure of the effectiveness of changes, corrections or improvements which have been made as a result of other studies 13 p-charts vs. x - R-charts • The p-chart is less powerful than x and R charts. It provides less information • With the x - R chart, we can study the process without regard to the specifications - the p-chart requires specs. • The p-chart cannot tell us whether nonconformances are caused by poor centering, excessive variability, or out-of-control conditions. 14 p-charts vs. x - R-charts • The p-chart cannot warn of trends or shifts unless they are so pronounced that they actually resulted in a change in the number of defective units produced. 15 Number of Nonconformities c - the total number of nonconformities in a unit 16 Number of Nonconformities Statistical Basis - The number of opportunities for nonconformities is infinitely large and the probability of occurrence of a nonconformity at any location is small and constant. Samples are of a constant size and the inspection unit is the same for each sample. X = number of nonconformities in the sample c x ec p( x ) P ( X x ) , x 0 ,1, ... , n x! where c = expected number of nonconformities 17 Control Chart for Nonconformities - The c-chart C - is the count of defects in a sample c = count c = average of the counts total nonconform ities total samples UCL c 3 c Center Line c LCL c 3 c 18 Average Number of Nonconformities Per Unit - u c u n Where c is the total nonconformities in a sample of n inspection units 19 Control Chart - The u-chart Occasionally, it is useful to work with defects per unit, particularly when the inspection unit consists of several physical units of product. Then if n = sample size, defined as a consistent area of opportunity U c total number of defects n area of opportunit y 20 Control Chart - The u-chart U UCL U 3 n Center Line U U UCL U 3 n n where U u i 1 n i 21