Statistics Homework: Probability, Confidence, Control Charts

advertisement

Homework

Set #1

2.1. The probability distribution of x is 𝑓(𝑥) = 𝑘𝑒 −𝑥 , 0 ≤ 𝑥 < ∞. Find the appropriate value

of k. Find the mean and variance of x.

2.2. A manufacturer of electronic calculators offers a one-year warranty. If the calculator fails

for any reason during this period, it is replaced. The time to failure is well modelled by the

following probability distribution:

𝑓(𝑥) = 0.125𝑒 −0.125𝑥

𝑥>0

a. What percentage of the calculators will fail within the warranty period?

b. The manufacturing cost of a calculator is $50, and the profit per sale is $25. What is

the effect of warranty replacements on profit?

2.3. The net contents in ounces of a canned soft drink is a random variable with probability

distribution

𝑓(𝑥) = {

4(𝑥 − 11.75)

4(12.75 − 𝑥)

11.75 ≤ 𝑥 ≤ 12.25

}

12.25 ≤ 𝑥 ≤ 12.75

Find the probability that a can contains less than 12 oz of product.

2.4. A lot of size N = 30 contains five nonconforming units. What is the probability that a

sample of five units selected at random contains exactly one nonconforming units? What is

the probability that it contains one or more nonconformances?

2.5. A quality characteristic of a product is normally distributed with mean µ and standard

deviation one. Specifications on the characteristic are 6 ≤ 𝑥 ≤ 8. A unit that falls within

specification on this quality characteristic results in a profit of C0. However, if 𝑥 < 6, the

profit is −C1, while if 𝑥 > 8, the profit is −C2. Find the value of µ that maximizes the

expected profit.

Set #2

3.1 The inside diameters of bearings used in an aircraft landing gear assembly are known to

have a standard deviation of 𝜎 =0.002 cm. A random sample of 15 bearing has an average

inside diameter of 8.2535 cm. Construct a 95% two-sided confidence interval on the mean

bearing diameter.

3.2 Two machines are used for filling glass bottles with a soft drink beverage. The filling

processes have known standard deviations 𝜎1 = 0.010 litre and 𝜎2 = 0.015 litre, respectively.

A random sample of 𝑛1 = 25 bottles from machine 1 and 𝑛2 = 20 bottles from machine 2

results in average net contents of 𝑥

̅̅̅1 = 2.04 litres and ̅̅̅

𝑥2 = 2.07 litres. Construct a 95%

confidence interval on the difference in mean fill volume. Based on the results of this

calculation, would you conclude that both machines fill to the same volume?

3.3. A random sample of 200 printed circuit boards contains 18 defective or nonconforming

units. Estimate the process fraction nonconforming. Construct a 90% two-sided confidence

interval on the true fraction nonconforming in the production process.

3.4. Consider the data in Question 3.1 above. Test the hypothesis that the mean inside bearing

diameter equals 8.25 cm.

3.5. A new purification unit is installed in a chemical process. Before its installation, a random

sample yielded the following data about the percentage of impurity: ̅̅̅

𝑥1 = 9.85, 𝑆12 = 81.73,

and 𝑛1 = 10. After installation, a random sample resulted in ̅̅̅

𝑥2 = 8.08, 𝑆22 = 78.46, and 𝑛2 =

8.

a. Can you conclude that the two variances are equal?

b. Can you conclude that the new purification device has reduced the mean percentage of

impurity?

3.6. Suppose we wish to test the hypothesis

𝐻0 : µ = 15

𝐻1 : µ ≠ 15

where we know that 𝜎 2 = 9.0. If the true mean is really 20, what sample size must be used to

ensure that the probability of type II error is no greater than 0.10? Assume that 𝛼 = 0.5

Set #3

4.1. Discuss the concepts of chance and assignable causes of variability and the part they play

in statistical quality control.

4.2. A normally distributed quality characteristic is monitored by a control chart with 3-sigma

control limits. Develop a general expression for the probability that a point will plot outside

the control limits when the process is really in control.

Set #4

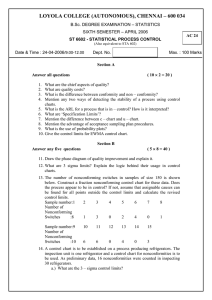

4.3. A process produces rubber belts in lots of size 2500. Inspection records on the last 20 lots

reveal the following data:

a. Compute trial control limits for a fraction nonconforming control chart.

b. If you wanted to set up a control chart for controlling future production, how would you

use the above data to obtain the center line and control limits for the chart?

4.4. A control chart indicates that the current process fraction nonconforming is 0.02. If the 50

items are inspected each day, what is the probability of detecting a shift in the fraction

nonconforming to 0.04 on the first day after the shift? By the end of the third day following the

shift?

4.5. A control chart is used to control the fraction nonconforming for a plastic part

manufactured in an injection molding process. Ten subgroups yield the following data:

a. Set up a control chart for the number nonconforming in samples of n = 100.

b. For the chart established in part (a), what is the probability of detecting a shift in the

process fraction nonconforming to 0.30 on the first sample after the shift has occurred?

4.6. A fraction nonconforming control chart with centre line 0.10, UCL = 0.19, and LCL = 0.01

is used to control a process.

a. If 3-sigma limits are used, to find the sample size for the control chart.

b. Use the Poisson approximation to the binomial to find the probability of type I error.

c. Use the Poisson approximation to the binomial to find the probability of type II

error if the process fraction defective is actually p = 0.20.

4.7. The data below are 𝑥̅ and R values for 24 samples of size n = 5 taken from a process

producing bearings. The measurements are made on the inside diameter of the bearing, with

only the last three decimals recorded (i.e., 34.5 should be 0.50345).

a. Set up 𝑥̅ and R charts on this process. Does the process seem to be in statistical

control? If necessary, revise the trial control limits.

b. If specifications on this diameter are 0.5030 ± 0.0010, fine the percentage of nonconformities produced by this process.

4.8. An 𝑥̅ chart is used to control the mean of a quality characteristic. It is known that σ = 6.0

and n = 4. The centre line = 200, UCL = 209, and LCL = 191. If the process mean shifts to 188,

find the probability that this shift is detected on the first subsequent sample.

Set #5

5.1 The data from an experiment to investigate the effect of glass type and phosphor type

on the brightness of a television tube is shown in the table below. The response measured

is the current necessary (in microamps) to obtain a specified brightness level. Analyse the

data and draw conclusions.

Glass Type

1

Phosphor Type

2

1

280

290

285

230

235

240

300

310

295

260

240

235

2

3

290

285

290

220

225

230

Set #6

6.1 A manufacturer claims that he can design and manufacture a radar set that will have a mean

time between failures of 240 hours based on the exponential distribution. Suppose that a

certain mission requires failure-free operation of the set for 24 hours. What is the chance that

the set will complete a mission without failure?

6.2 The average life of subassembly A is 2,000 hours. Data indicate that this life characteristic is

exponentially distributed.

a. What percent of the subassemblies in the population will last at least 200 hours?

b. The average life subassembly B is 1,000 hours and the life is exponentially distributed.

What percent of the subassemblies in the population will last at least 200 hours?

c. These subassemblies are independently manufactured and then connected in series to

form the total assembly. What percent of assemblies in the population will last at least

200 hours?