Continual Improvement

advertisement

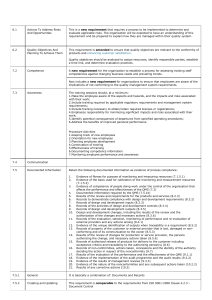

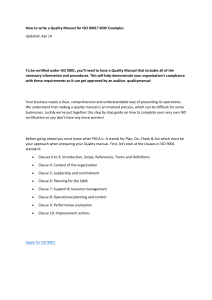

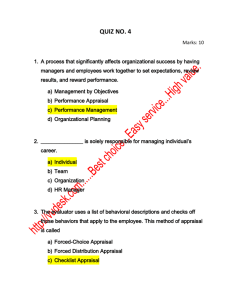

CONTINUOUS BUSINESS IMPROVEMENT ACTIVITY BASED BUSINESS SYSTEMS Using Quality Management Systems Principles Continuous Improvement © Page 1 CONTINUOUS BUSINESS IMPROVEMENT MODEL ISO 9001:2000 Quality system combines Processes into overall activities. There are 4 categories into which each of these individual processes is identified. Infrastructure Production Activities ISO 9001:2000 clause 1.0 Management Responsibility clause 2. 0 Resource Management clause 4.0 Measurement and Analysis ISO 9001:2000 clause 3.0 Process Management Management Responsibility Anticipate Customer Needs Resources Evaluate process and resource capabilities Measurement and Analysis Accept Tender Records Continuous Improvement Activity Based Business System Design Product Produce Product Ship Product Invoice Customer Continuous Improvement © Page 2 Total Customer Satisfaction Meet Requirements Exceed Expectations Internal & External More for less $$$ Continuous Business Improvement Eliminate Defects Quality Management Reduce Cycle time Customer Focus Total Company Involvement Employee Involvement Programs Empowerment Education/Training Quality Implementation Strategy Continuous Improvement © Page 3 THE PRICE OF QUALITY COST The process of obtaining quality costs does not necessarily include a revision of the accounting system of the company. This would be very expensive and would delay implementation of quality costs analysis by a year or more. The current accounting system can be used to ESTIMATE the quality costs in a number of categories, e.g., many appraisal, internal and external failure costs. For those costs that are not obtained in this manner, interviews with supervisors, engineers, technicians, and operators can be used to estimate those portions of the direct and indirect labor, plus burden of the various units that support the four quality cost activities. A typical company has a cost of quality (really a cost of non-quality) which is about 20% of the manufacturing cost of the product. Of this quality cost figure, the same typical company will spend the following percentages. Prevention 5% Appraisal 47% Internal Failure 46% External Failure 2% This profile indicates that rather little effort is invested in making the product right the first time; but to the credit of the manufacturer, very little nonconforming product is seen by the customer. The costs for this are substantial. That is why the cost of quality is so high relative to the manufacturing costs. The traditional way of looking at profit is: COST + PROFIT = PRICE In the world market of today, the price is set by what the customer is willing to pay, the resulting formula is; PRICE – COST = PROFIT The way to profit is reduction in costs. Specifically, it is done by increasing the expenditures to PREVENT nonconforming product. By making products right the first time and assuring that the process continues to function correctly, the cost of appraisal and failure can be reduced to less than half that at the start of the cost improvement program. It can ONLY be accomplished by improving quality, i.e. making the product right the first time . A well-documented and implemented Quality System will put into place effective, efficient and proactive systems to address the cost centers described above, these systems will promote early awareness of processes out of control and their resulting costs. Continuous Improvement © Page 4 Quality Costs and Other Measures Quality Costs are categorized into four separate types of costs (Juran & Gryna, pp. 12-34 McGraw Hill, 1980) Prevention Costs– those costs incurred in order to prevent failure and to minimize appraisal costs. Typical examples of this type are: quality planning, design reviews, training, quality training, process control development and implementation, process capability studies, data acquisition for quality analysis, quality reports, and quality improvement projects. Appraisal Costs– those costs incurred in order to discover the condition of the product. Typical examples of this type are: incoming material inspection, inspection and testing during production and after production to assure conformance to the requirements, maintaining the accuracy of the test equipment, evaluation of raw material, in-process inventory and finished good inventories to determine degradation, and all of the materials and services used to conduct these appraisals. Internal Failure Costs– those costs which accrue because the raw materials, inprocess materials or components, or finished goods are not manufactured right the first time. These costs can be eliminated if suitable steps are taken. Typical examples of these costs are: scrap, rework, retest, downtime, yield loss, disposition, remedial engineering, excessive lead time and inventory costs, overproduction, and increased non-value added cycle time. External Failure Costs – those costs which occur because the customer discovers a lack of conformance of the product to requirements or expectations of the user. These costs can also be eliminated if suitable steps are taken. Typical examples of these costs are: complaint investigation, processing and adjustments, costs associated with the return and replacement of nonconforming products; all warranty costs and the maintenance of these contracts; and all concessions made to customers because of nonconforming product. Also included in this category is the loss of business, i.e., sales and revenue, due to loss of customer and the influence of this customer on other customers or potential customers. This cost is very difficult to estimate but one resource has suggested that the loss is 20% of the sales price per incident . Continuous Improvement © Page 5 Quality Maturity Curve or “S” Curve TQC Reward of Goal Made Measurement Continuous Improvement Implementation Training & Education Develop Quality Plan & Strategy Understanding Modern Quality Management Measurement Recognition of Need, Awareness Start Continuous Improvement © Page 6 Keys to Implementing a Total Quality System ! ! ! ! ! ! ! ! Company-wide quality attitude Measurement of Cost Design of product to customer requirements Design for process capability Partnerships with vendors Statistical process control Experimental design to optimize processes Marketing quality strategic advantage Continuous Improvement © Page 7 The Quality Perspective Section 1.4 ISO 9001:2000 Employee involvement programs are an integral part of a total quality strategy. Their role is to encourage individuals and teams to identify problems and opportunities for improvement through focus on the work process. These programs provide a framework to actively promote communication of ideas, and an environment that will actively encourage their implementation. Documentation and Reports A significant element of any quality discipline is the need to document the process, and to measure and track the results of those changes. These reports reflect the following; ! Measurements ! Trend data ! Status ! Analysis of improvement Continuous Improvement © Page 8