here

advertisement

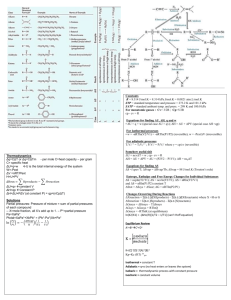

CHE 441 __________________ LAST NAME, FIRST Problem set #5 Figure 1b PFD for the Production of Acrylic Acid from Propylene 1. For the accrylic process shown in Figure 1b (Turton et al, Analysis, Synthesis, and Design of Chemical Processes), check the design specifications for the reflux pump P-305 (shaft power = 1.2 kW, Pout = 3.31 bar) against the heuristics in Table 3.5. You can neglect the frictional loss in the lines so that the pressure increase across the pump may be estimated to be the static head between V-302 and top of T-305 (you can use the tower height, 25 m, for the calculation) plus the pressure drop across the control valve (Table 3.4). Flow of acetic acid (stream 18 + stream 19) is 5650 kg/h. Density of acetic acid at 46oC is 1020 kg/m3. 2. For the accrylic process shown in Figure 1b, check the design specifications for the acid reflux drum V-302 (D = 1.0 m, L = 2.5 m) against the heuristics in Table 3.2. Flow of acetic acid (stream 18 + stream 19) is 5650 kg/h. Density of acetic acid at 46oC is 1020 kg/m3. 3. Normal butane (A), C4H10, is to be isomerized to isobutane (B) in a plug-flow reactor1. The reaction is to be carried out adiabatically in the liquid phase under high pressure using essentially trace amount of a liquid catalyst which gives a specific rate constant of 31.1 h-1 at 360oK. Calculate the fractional conversion of a PFR with a volume of 3.0 m3 necessary to process 150 kmol/h of a mixture 80 mol % n-butane and 20 mol % i-pentane, which is considered an inert. The feed enter at 330oK. 1 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall, 1999, pg. 454 k A B kb Data: HRx = 6,900 J/mol, Cp,n-B = CpA = 141 J/moloK, Cp,i-B = CpB = 141 J/moloK, Cp,i-P = k 161 J/moloK, activation energy = 65.7 kJ/mol, CA0 = 9.3 kmol/m3, Keq = = 3.03 at 333oK. kb 4. A two-stage steam jet is to be used on a large vacuum system. It is estimated that 10 kg of air must be removed from the system each hour. The vapors being removed will contain water vapor at a pressure equivalent to the equilibrium vapor pressure of water at 15oC. If a suction pressure of 50 mmHg absolute is to be maintained by the steam jet, estimate the kilograms of steam per hour that will be required to operate the jet. Use the following table. Average consumption in kg/h of 775-kPa steam in a steam-jet ejector to provide Various levels of vacuum Capacity Wt% net Suction pressure, mmHg absolute (kg/h) dry air in 12.5 25 37.5 50 75 100 gas-vapor gas-vapor 323222221mixture stage stage stage stage stage stage stage stage stage handled 4.5 100 33 45 27 32 26 23 19 17 26 4.5 70 27 38 21 27 22 19 16 14 29 4.5 40 20 31 15 21 21 15 12 10 31 4.5 10 11 20 7 13 13 8 6 5 34 Note: the dry air is noncondensibles. 150 1stage 16 17 18 19 5. Hydrogen gas at a temperature of 20oC and an absolute pressure of 1380 kPa undergoes compression to 4140 kPa. If the mechanical efficiency of the compressor is 55 percent on the basis of an isothermal and reversible operation, determine the kilograms of hydrogen that can be compressed per second when the power supplied to the compressor is 224 kW. Assume that the kinetic energy effects can be neglected. Also evaluate the mechanical efficiency of the compressor on the basis of an adiabatic and reversible operation. Assume that a single-stage compressor is used and the ratio of Cp/Cv remains constant at 1.4. 6. A centrifugal fan is used to remove stagnant air in a large hangar at a pressure of 100 kPa and a temperature of 32oC and discharge it externally at a pressure of 103 kpa and a velocity of 40 m/s. Determine the power requirement needed for the removal of 4.7 std m3/s of air. The efficiency of the fan can be assumed to be 65 percent. 7. What power input in kW will be required to mix a rubber latex compound with a viscosity of 1.2×105 cP and a density of 1121 kg/m3 in the same mixer that was used in Example 12-6 (Peters and Timmerhaus). Would there be any difference in the power requirement if baffles were added to the mixing tank? 8. What power will be required to mix an aqueous solution of 50% NaOH in a baffled tank, 2 m in diameter? The mixing will be performed in the vertical tank filled to a height of 2 m by a disk turbine with six flat blades. The turbine is 0.67 m in diameter and positioned 0.67 m above the bottom of the tank. The turbine blades are 0.134 m wide and turn at 90 r/min. The solution has a viscosity of 0.012 Pa∙s and a density of 1500 kg/m3.