chapter6

advertisement

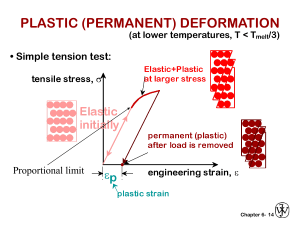

Chapter 6: Mechanical Properties ISSUES TO ADDRESS... • Stress and strain: What are they and stress-strain curve. • Elastic behavior: When loads are small, how much deformation occurs? What materials deform least? • Plastic behavior: At what point does permanent deformation occur? What materials are most resistant to permanent deformation? • Ductility, Toughness, Resilience, Hardness Chapter 6 - 1 CONCEPTS OF STRESS AND STRAIN • If a load is static or changes relatively slowly with time and is applied uniformly over a cross section or surface of a member, the mechanical behavior may be ascertained by a simple stress–strain test; • There are four principal ways in which a load may be applied: namely, tension, compression, shear, and torsion Chapter 6 - 2 Chapter 6 - 3 Elastic Deformation 1. Initial 2. Small load 3. Unload bonds stretch return to initial d F Elastic means reversible Time independent! F Linearelastic d Non-Linearelastic Chapter 6 - 4 Plastic Deformation (Metals) 1. Initial 2. Small load bonds stretch & planes shear delastic + plastic 3. Unload planes still sheared dplastic F F Plastic means permanent! linear elastic linear elastic dplastic d Chapter 6 - 5 Engineering Stress • Tensile stress, s: • Shear stress, t: Ft F Area, A Area, A Ft Ft lb f N = 2 or s= 2 in m Ao original area before loading Ft Fs Fs Fs t= Ao Ft F Stress has units: N/m2 or lbf/in2 Chapter 6 - 6 Common States of Stress • Simple tension: cable F F A o = cross sectional area (when unloaded) F s= s Ao s • Torsion (a form of shear): drive shaft M Ac M Fs Ski lift Ao MR t = Io 2R Chapter 6 - 7 OTHER COMMON STRESS STATES (1) • Simple compression: Ao Canyon Bridge, Los Alamos, NM (photo courtesy P.M. Anderson) Balanced Rock, Arches National Park (photo courtesy P.M. Anderson) F s= Ao Note: compressive structure member (s < 0 here). Chapter 6 - 8 OTHER COMMON STRESS STATES (2) • Bi-axial tension: Pressurized tank (photo courtesy P.M. Anderson) • Hydrostatic compression: Fish under water sq > 0 sz > 0 (photo courtesy P.M. Anderson) sh< 0 Chapter 6 - 9 Engineering Strain • Tensile strain: • Lateral strain: d/2 e = d Lo wo d = L=L-L0 • Shear strain: eL = Lo dL wo d L = W W0 dL /2 q g = x/y = tan q x 90º - q y 90º Strain is always dimensionless. Chapter 6 - 10 Stress-Strain Testing • Typical tensile test machine • Typical tensile specimen Load measured extensometer specimen Strain measured gauge length We can obtained many important properties of materials from stress-strain diagram Chapter 6 - 11 (linear)Elastic Properties of materials • Modulus of Elasticity, E : (also known as Young's modulus) • Hooke's Law: s=Ee s F E e Linearelastic F simple tension test Chapter 6 - 12 Poisson's ratio, n • Poisson's ratio, n: eL n= e metals: n ~ 0.33 ceramics: n ~ 0.25 polymers: n ~ 0.40 Units: E: [GPa] or [psi] n: dimensionless Chapter 6 - 13 Mechanical Properties • Slope of stress strain plot (which is proportional to the elastic modulus) depends on bond strength of metal The magnitude of E is measured of the resistance to separation of adjacent atoms, that is, the interatomic bonding forces So E α (dF/dr) Chapter 6 - 14 T – E diagram Plot of modulus of elasticity versus temperature for tungsten, steel, and aluminum. Chapter 6 - 15 Other Elastic Properties • Elastic Shear modulus, G: stress t M G t=Gg g strain • Elastic Bulk modulus, K: V P = -K Vo M P P K V P Vo • Special relations for isotropic materials: E G= 2(1 + n) simple torsion test E K= 3(1 2n) P pressure test: Init. vol =Vo. Vol chg. = V Chapter 6 - 16 Young’s Moduli: Comparison Metals Alloys 1200 1000 800 600 400 E(GPa) 200 100 80 60 40 Graphite Composites Ceramics Polymers /fibers Semicond Diamond Tungsten Molybdenum Steel, Ni Tantalum Platinum Cu alloys Zinc, Ti Silver, Gold Aluminum Magnesium, Tin Si carbide Al oxide Si nitride Carbon fibers only CFRE(|| fibers)* <111> Si crystal Aramid fibers only <100> AFRE(|| fibers)* Glass -soda Glass fibers only GFRE(|| fibers)* Concrete 109 Pa GFRE* 20 10 8 6 4 2 1 0.8 0.6 0.4 0.2 CFRE* GFRE( fibers)* Graphite Polyester PET PS PC CFRE( fibers) * AFRE( fibers) * Composite data based on reinforced epoxy with 60 vol% of aligned carbon (CFRE), aramid (AFRE), or glass (GFRE) fibers. Epoxy only PP HDPE PTFE LDPE Wood( grain) Chapter 6 - 17 Useful Linear Elastic Relationships • Simple tension: d = FL o d = n Fw o L EA o EA o F a= wo 2ML o pr o4 G M = moment a = angle of twist d/2 Ao dL /2 • Simple torsion: Lo Lo 2ro • Material, geometric, and loading parameters all contribute to deflection. • Larger elastic moduli minimize elastic deflection. Chapter 6 - 18 Chapter 6 - 19 Chapter 6 - 20 Plastic (Permanent) Deformation (at lower temperatures, i.e. T < Tmelt/3) • Simple tension test: Elastic+Plastic at larger stress engineering stress, s Yielding stress y Elastic initially permanent (plastic) after load is removed ep engineering strain, e plastic strain Chapter 6 - 21 Plastic properties of materials • • • • • Yield Strength, sy Tensile Strength, TS Ductility Toughness Resilience, Ur Chapter 6 - 22 Yield Strength, sy • Stress at which noticeable plastic deformation has occurred. when ep = 0.002 tensile stress, s sy sy = yield strength Note: for 2 inch sample e = 0.002 = z/z z = 0.004 in engineering strain, e ep = 0.002 Chapter 6 - 23 Yield Strength : Comparison Metals/ Alloys Graphite/ Ceramics/ Semicond Polymers Composites/ fibers 2000 200 Al (6061) ag Steel (1020) hr Ti (pure) a Ta (pure) Cu (71500) hr 100 70 60 50 40 Al (6061) a 30 20 10 Tin (pure) ¨ dry PC Nylon 6,6 PET PVC humid PP HDPE LDPE Hard to measure, 300 in ceramic matrix and epoxy matrix composites, since in tension, fracture usually occurs before yield. 700 600 500 400 Ti (5Al-2.5Sn) a W (pure) Cu (71500) cw Mo (pure) Steel (4140) a Steel (1020) cd since in tension, fracture usually occurs before yield. 1000 Hard to measure , Yield strength, sy (MPa) Steel (4140) qt Room T values a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered Chapter 6 - 24 Tensile Strength, TS • Maximum stress on engineering stress-strain curve. TS F = fracture or ultimate strength engineering stress sy Typical response of a metal Neck – acts as stress concentrator strain engineering strain • Metals: occurs when noticeable necking starts. • Polymers: occurs when polymer backbone chains are aligned and about to break. Chapter 6 - 25 Tensile Strength : Comparison Metals/ Alloys Tensile strength, TS (MPa) 5000 3000 2000 1000 300 200 100 40 30 Graphite/ Ceramics/ Semicond Polymers C fibers Aramid fib E-glass fib Steel (4140) qt AFRE(|| fiber) GFRE(|| fiber) CFRE(|| fiber) Diamond W (pure) Ti (5Al-2.5Sn)aa Steel (4140) Si nitride Cu (71500) cw Cu (71500) hr Al oxide Steel (1020) ag Al (6061) a Ti (pure) Ta (pure) Al (6061) a Si crystal <100> Glass-soda Concrete Room Temp. values Nylon 6,6 PC PET PVC PP HDPE 20 Composites/ fibers Graphite wood(|| fiber) GFRE( fiber) CFRE( fiber) AFRE( fiber) LDPE 10 wood ( 1 fiber) a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered AFRE, GFRE, & CFRE = aramid, glass, & carbon fiber-reinforced epoxy composites, with 60 vol% fibers. Chapter 6 - 26 Ductility Ductility can be expressed quantita • Plastic tensile strain at failure: Lf Lo x 100 %EL = Percent elongation Lo smaller %EL Engineering tensile stress, s brittle larger %EL Lo ductile Ao Af Lf Engineering tensile strain, e • Another ductility measure: Percent reduction of area %RA = Ao - Af x 100 Ao Chapter 6 - 27 Ductility • Brittle materials are approximately considered to be those having a fracture strain of less than about 5%. • Brittle materials have little or no plastic deformation upon fracture Chapter 6 - 28 Toughness • Energy to break a unit volume of material or it is a measure of the ability of a material to absorb energy up to fracture( or impact resistance) • Approximate by the area under the stress-strain curve. Engineering tensile stress, s small toughness (ceramics) large toughness (metals) very small toughness (unreinforced polymers) Engineering tensile strain, e Brittle fracture: elastic energy( no apparent plastic deformation takes place fracture) Ductile fracture: elastic + plastic energy(extensive plastic deformation takes place before fracture) Chapter 6 - 29 Fracture toughness is a property indicative of a material’s resistance to fracture when a crack is present For a material to be tough, it must display both strength and ductility; and often, ductile materials are tougher than brittle ones Chapter 6 - 30 Resilience, Ur • Ability of a material to store energy when it is deformed elastically, and then, upon unloading, to have this energy recovered – Energy stored best in elastic region Ur = ey 0 sde If we assume a linear stress-strain curve this simplifies to 1 Ur @ sy e y 2 Area under s- e curve taken to yielding(the shaded area) Chapter 6 - 31 1 1 s y s y U r = s ye y = s y = 2 2 E 2E 2 Modulus of resilience ( is the area under curve) Thus, resilient materials are those having high yield strengths and low module of elasticity; such alloys would be used in spring applications. Chapter 6 - 32 Elastic Strain Recovery Chapter 6 - 33 Hardness • Resistance to permanently indenting the surface, or is a measure of a materials resistance to deformation by surface indentation or by abrasion. • Large hardness means: --resistance to plastic deformation or cracking in compression. --better wear properties. e.g., 10 mm sphere D most plastics brasses Al alloys measure size of indent after removing load apply known force Smaller indents mean larger hardness. d easy to machine steels file hard cutting tools nitrided steels diamond increasing hardness Chapter 6 - 34 Hardness: Measurement • Rockwell – No major sample damage – Each scale runs to 130 but only useful in range 20-100. – Minor load 10 kg – Major load 60 (A), 100 (B) & 150 (C) kg • A = diamond, B = 1.588 mm ball of steel, C = diamond • the hardness can be taken directly from the machine, so it is a quick test • HB = Brinell Hardness - P= 500, 1500, 3000 kg – TS (psia) = 500 x HB – TS (MPa) = 3.45 x HB (The HB and tensile strength relationship) Chapter 6 - 35 Hardness: Measurement Table 6.5 Chapter 6 - 36 problem Material Yielding strength ( MPa) Tensile strength ( MPa) Strain at fracture Fracture strength (MPa) Elastic modulus (GPa) A 310 340 0.23 265 210 B 100 120 0.4 105 150 C 415 550 0.15 500 310 D 700 850 0.14 720 210 E Fracture before yielding 650 350 a) Which experience the greatest percent reduction in area? Why? b) Which is the strongest? Why? c) Which is the stiffest? Why? d) Which is the hardest? Why? Chapter 6 - 37 a) Material B will experience the greatest percent area reduction since it has the highest strain at fracture, and, therefore is most ductile. b) Material D is the strongest because it has the highest yield and tensile strengths. c) Material E is the stiffest because it has the highest elastic modulus. stiffness=E=σ/ε, the higher E the material more stiffest d) Material D is the hardest because it has the highest tensile strength. Chapter 6 - 38 Problem: Chapter 6 - 39 True Stress & Strain Note: Surf.Are. changes when sample stretched • True stress • True Strain sT = F Ai eT = ln i o sT = s1 + e eT = ln1 + e Chapter 6 - 40 Hardening • An increase in sy due to plastic deformation. s large hardening sy 1 sy small hardening 0 e • Curve fit to the stress-strain response: The region of the true stress-strain curve from the onset of plastic deformation to the point at which necking begins may be approximated by sT = K eT “true” stress (F/Ai ) n hardening exponent: n = 0.15 (some steels) to n = 0.5 (some coppers) “true” strain: ln(L/Lo) (n and K constants) Chapter 6 - 41 Design or Safety Factors • Design uncertainties mean we do not push the limit. • Factor of safety, N Often N is Safe stress, or sworking = sy N between 1.2 and 4 The choice of an appropriate value of N is necessary. If N is too large, then component overdesign will result, that is, either too much material or a material having a higherthan-necessary strength will be used. Values normally range between1.2 and 4.0. Selection of N will depend on a number of factors, including economics, previous experience, the accuracy with which mechanical forces and material properties may be determined, and, most important, the consequences of Chapter 6 - 42 failure in terms of loss of life and/or property damage. Example: Calculate a diameter, d, to ensure that yield does not occur in the 1045 carbon steel rod below. Use a factor of safety of 5. sworking = 220,000N p d2 / 4 5 sy N d 1045 plain carbon steel: sy = 310 MPa TS = 565 MPa Lo F = 220,000N d = 0.067 m = 6.7 cm Chapter 6 - 43 problem Chapter 6 - 44 Chapter 6 - 45 Summary • Stress and strain: These are size-independent measures of load and displacement, respectively. • Elastic behavior: This reversible behavior often shows a linear relation between stress and strain. To minimize deformation, select a material with a large elastic modulus (E or G). • Plastic behavior: This permanent deformation behavior occurs when the tensile (or compressive) uniaxial stress reaches sy. • Toughness: The energy needed to break a unit volume of material. • Ductility: The amount of plastic strain that has occurred at fracture. Chapter 6 - 46 problem A brass alloy is known to have a yield strength of 240 MPa (35,000 psi), a tensile strength of 310 MPa (45,000 psi), and an elastic modulus of 110 GPa (16.0 10 6 psi). A cylindrical specimen of this alloy 15.2 mm (0.60 in.) in diameter and 380 mm (15.0 in.) long is stressed in tension and found to elongate 1.9 mm (0.075 in.). On the basis of the information given, is it possible to compute the magnitude of the load that is necessary to produce this change in length? If so, calculate the load. If not, explain why. Chapter 6 - 47 We are asked to ascertain whether or not it is possible to compute, for brass, the magnitude of the load necessary to produce an elongation of 1.9 mm (0.075 in.). It is first necessary to compute the strain at yielding from the yield strength and the elastic modulus, and then the strain experienced by the test specimen. Then, if ε(test) < ε(yield) deformation is elastic, and the load may be computed using Equations 6.1 and 6.5. However, if F (s = A , s = Ee ) ε(test) > ε(yield) computation of the load is not possible inasmuch as deformation is plastic and we have neither a stress-strain plot nor a mathematical expression relating plastic stress and strain. We compute these two strain values as Chapter 6 - 48 Therefore, computation of the load is not possible since ε(test) > ε(yield). Chapter 6 - 49 problem A cylindrical metal specimen having an original diameter of 12.8 mm(0.505 in.) and gauge length of 50.80 mm (2.000 in.) is pulled in tension until fracture occurs. The diameter at the point of fracture is 8.13 mm (0.320 in.), and the fractured gauge length is 74.17 mm (2.920 in.). Calculate the ductility in terms of percent reduction in area and percent elongation. Chapter 6 - 50 This problem calls for the computation of ductility in both percent reduction in area and percent elongation. Percent reduction in area is computed using Equation 6.12 as in which d0 and df are, respectively, the original and fracture cross-sectional areas. Thus, While, for percent elongation, we use Equation 6.11 as Chapter 6 - 51