CHAPTER 6: MECHANICAL PROPERTIES

advertisement

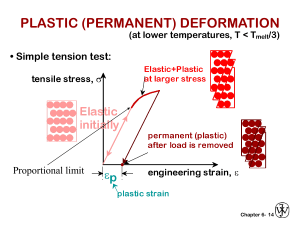

CHAPTER 7: MECHANICAL PROPERTIES ISSUES TO ADDRESS... • Stress and strain: What are they and why are they used instead of load and deformation? • Elastic behavior: When loads are small, how much deformation occurs? What materials deform least? • Plastic behavior: At what point do dislocations cause permanent deformation? What materials are most resistant to permanent deformation? • Toughness and ductility: What are they and how do we measure them? • Ceramic Materials: What special provisions/tests are made for ceramic materials? 1 ELASTIC DEFORMATION 1. Initial 2. Small load 3. Unload bonds stretch return to initial F Elastic means reversible! 2 PLASTIC DEFORMATION (METALS) 1. Initial 2. Small load 3. Unload F Plastic means permanent! linear elastic linear elastic plastic 3 ENGINEERING STRESS • Tensile stress, s: • Shear stress, t: Ft s Ao original area before loading Stress has units: N/m2 or lb/in2 4 ENGINEERING STRAIN • Tensile strain: • Lateral strain: /2 wo • Shear strain: L/2 Lo /2 L/2 /2 = tan /2 - /2 Strain is always dimensionless. /2 8 STRESS-STRAIN TESTING • Typical tensile specimen • Typical tensile test machine Adapted from Fig. 6.2, Callister 6e. • Other types of tests: --compression: brittle materials (e.g., concrete) --torsion: cylindrical tubes, shafts. Adapted from Fig. 6.3, Callister 6e. (Fig. 6.3 is taken from H.W. Hayden, W.G. Moffatt, and J. Wulff, The Structure and Properties of Materials, Vol. III, Mechanical Behavior, p. 2, John Wiley and Sons, New York, 1965.) 9 LINEAR ELASTIC PROPERTIES • Modulus of Elasticity, E: (also known as Young's modulus) • Hooke's Law: s=Ee • Poisson's ratio, n: metals: n ~ 0.33 ceramics: ~0.25 polymers: ~0.40 Units: E: [GPa] or [psi] n: dimensionless 10 OTHER ELASTIC PROPERTIES • Elastic Shear modulus, G: t=G M t G 1 simple torsion test M • Elastic Bulk modulus, K: P P • Special relations for isotropic materials: E E G K 2(1 n) 3(1 2n) P pressure test: Init. vol =Vo. Vol chg. = DV 12 YOUNG’S MODULI: COMPARISON Metals Alloys 1200 1000 800 600 400 E(GPa) 200 100 80 60 40 109 Pa Graphite Composites Ceramics Polymers /fibers Semicond Diamond Tungsten Molybdenum Steel, Ni Tantalum Platinum Cu alloys Zinc, Ti Silver, Gold Aluminum Magnesium, Tin Si carbide Al oxide Si nitride Carbon fibers only CFRE(|| fibers)* <111> Si crystal Aramid fibers only <100> AFRE(|| fibers)* Glass-soda Glass fibers only GFRE(|| fibers)* Concrete GFRE* 20 10 8 6 4 2 1 0.8 0.6 0.4 0.2 CFRE* GFRE( fibers)* Graphite Polyester PET PS PC CFRE( fibers)* AFRE( fibers)* Epoxy only PP HDPE PTFE LDPE Wood( grain) 13 PLASTIC (PERMANENT) DEFORMATION (at lower temperatures, T < Tmelt/3) • Simple tension test: 15 YIELD STRENGTH, sy • Stress at which noticeable plastic deformation has occurred. when ep = 0.002 tensile stress, s sy engineering strain, e ep = 0.002 16 YIELD STRENGTH: COMPARISON sy(ceramics) >>sy(metals) >> sy(polymers) Room T values Based on data in Table B4, Callister 6e. a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered 17 TENSILE STRENGTH, TS • Maximum possible engineering stress in tension. Adapted from Fig. 6.11, Callister 6e. • Metals: occurs when noticeable necking starts. • Ceramics: occurs when crack propagation starts. • Polymers: occurs when polymer backbones are aligned and about to break. 18 TENSILE STRENGTH: COMPARISON TS(ceram) ~TS(met) ~ TS(comp) >> TS(poly) Room T values Based on data in Table B4, Callister 6e. a = annealed hr = hot rolled ag = aged cd = cold drawn cw = cold worked qt = quenched & tempered AFRE, GFRE, & CFRE = aramid, glass, & carbon fiber-reinforced epoxy composites, with 60 vol% fibers. 19 DUCTILITY, %EL L f Lo x100 • Plastic tensile strain at failure: %EL Lo Adapted from Fig. 6.13, Callister 6e. Ao A f • Another ductility measure: %AR x100 Ao • Note: %AR and %EL are often comparable. --Reason: crystal slip does not change material volume. --%AR > %EL possible if internal voids form in neck. 20 TOUGHNESS • Energy to break a unit volume of material • Approximate by the area under the stress-strain curve. Engineering tensile stress, s smaller toughness (ceramics) larger toughness (metals, PMCs) smaller toughnessunreinforced polymers Engineering tensile strain, e 21 HARDENING • An increase in sy due to plastic deformation. • Curve fit to the stress-strain response: 22 MEASURING ELASTIC MODULUS • Room T behavior is usually elastic, with brittle failure. • 3-Point Bend Testing often used. --tensile tests are difficult for brittle materials. Adapted from Fig. 12.29, Callister 6e. • Determine elastic modulus according to: E F L3 4bd3 rect. cross section F L3 12R 4 circ. cross section 23 MEASURING STRENGTH • 3-point bend test to measure room T strength. cross section d b rect. L/2 F L/2 Adapted from Fig. 12.29, Callister 6e. R circ. location of max tension • Typ. values: • Flexural strength: fail s fs s m 1.5FmaxL bd2 rect. FmaxL R3 sfs(MPa) Si nitride 700-1000 Si carbide 550-860 Al oxide 275-550 glass (soda) 69 Material E(GPa) 300 430 390 69 Data from Table 12.5, Callister 6e. 24 TENSILE RESPONSE: ELASTOMER CASE Stress-strain curves adapted from Fig. 15.1, Callister 6e. Inset figures along elastomer curve (green) adapted from Fig. 15.14, Callister 6e. (Fig. 15.14 is from Z.D. Jastrzebski, The Nature and Properties of Engineering Materials, 3rd ed., John Wiley and Sons, 1987.) • Compare to responses of other polymers: --brittle response (aligned, cross linked & networked case) --plastic response (semi-crystalline case) 25 T AND STRAIN RATE: THERMOPLASTICS • Decreasing T... --increases E --increases TS --decreases %EL • Increasing strain rate... --same effects as decreasing T. Adapted from Fig. 15.3, Callister 6e. (Fig. 15.3 is from T.S. Carswell and J.K. Nason, 'Effect of Environmental Conditions on the Mechanical Properties of Organic Plastics", Symposium on Plastics, American Society for Testing and Materials, Philadelphia, PA, 1944.) 26 TIME DEPENDENT DEFORMATION • Stress relaxation test: --strain to eo and hold. --observe decrease in stress with time. • Data: Large drop in Er for T > Tg. (amorphous polystyrene) Adapted from Fig. 15.7, Callister 6e. (Fig. 15.7 is from A.V. Tobolsky, Properties and Structures of Polymers, John Wiley and Sons, Inc., 1960.) • Relaxation modulus: s(t ) Er (t ) eo • Sample Tg(C) values: PE (low Mw) PE (high Mw) PVC PS PC -110 - 90 + 87 +100 +150 Selected values from Table 15.2, Callister 6e. 27 HARDNESS • Resistance to permanently indenting the surface. • Large hardness means: --resistance to plastic deformation or cracking in compression. --better wear properties. Adapted from Fig. 6.18, Callister 6e. (Fig. 6.18 is adapted from G.F. Kinney, Engineering Properties and Applications of Plastics, p. 202, John Wiley and Sons, 1957.) 28 DESIGN OR SAFETY FACTORS • Design uncertainties mean we do not push the limit. • Factor of safety, N Often N is between sy s working 1.2 and 4 N • Ex: Calculate a diameter, d, to ensure that yield does not occur in the 1045 carbon steel rod below. Use a factor of safety of 5. s working 220,000N 2 d / 4 sy N 5 29 Thermal Expansion Materials change size when temperature is changed initial final Tinitial Tfinal Tfinal > Tinitial final initial α (Tfinal Tinitial ) initial linear coefficient of thermal expansion (1/K or 1/°C) 25 Atomic Perspective: Thermal Expansion Asymmetric curve: -- increase temperature, -- increase in interatomic separation -- thermal expansion Symmetric curve: -- increase temperature, -- no increase in interatomic separation -- no thermal expansion 26 Coefficient of Thermal Expansion: Comparison Material increasing a • Polymers Polypropylene Polyethylene Polystyrene Teflon • Metals Aluminum Steel Tungsten Gold • Ceramics Magnesia (MgO) Alumina (Al2O3) Soda-lime glass Silica (cryst. SiO2) a (10-6/C) at room T 145-180 106-198 90-150 126-216 23.6 12 4.5 14.2 Polymers have larger a values because of weak secondary bonds • Q: Why does a generally decrease with increasing bond energy? 13.5 7.6 9 0.4 27 Thermal Stresses • Occur due to: -- restrained thermal expansion/contraction -- temperature gradients that lead to differential dimensional changes Thermal stress s Ea (T0 Tf ) Ea DT 28 SUMMARY • Stress and strain: These are size-independent measures of load and displacement, respectively. • Elastic behavior: This reversible behavior often shows a linear relation between stress and strain. To minimize deformation, select a material with a large elastic modulus (E or G). • Plastic behavior: This permanent deformation behavior occurs when the tensile (or compressive) uniaxial stress reaches sy. • Toughness: The energy needed to break a unit volume of material. • Ductility: The plastic strain at failure. Note: For materials selection cases related to mechanical behavior, see slides 20-4 to 20-10. 30