The Impacts of Wind Energy on Rural Alaska Diesel Power Systems

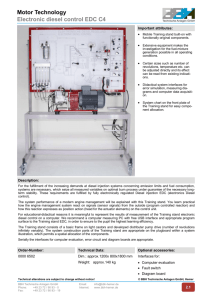

advertisement

Unintended Consequences: The Impacts of Wind Energy on Rural Alaska Diesel Power Systems David Lockard and Alan Fetters, Alaska Energy Authority Presentation Goals • Describe impacts of wind turbines on rural Alaska diesel power system operation (a moving target) • Assess significance of those impacts • Discuss opportunities to optimize operation of wind and diesel components of wind-diesel power systems Wind Impacts on Power Systems Technology Estimated Reduction in Fuel Savings Comments Heat Recovery 10-25% May be jacket-water, wet manifold, or stack HR Diesel Efficiency ?-30% See genset manufacturer’s efficiency curve. Also depends on penetration level. Wind Turbine Station Service 1-8% Resistance heaters (controls, powerhouses, transmissions), meters, controls, startup power, etc. Power Factor Correction 1-3% Sychronous converters, capacitors, “big iron”, static VAR compensators, etc. (Unalakleet PF < 0.4 at times) Line and transformer losses 2-5% Typical losses based on design criteria Wind energy used for thermal purposes 50% Oil heating efficiency is approximately twice diesel generation efficiency Cat 3456 w/ Custom Wet Manifold Before After Chitina Stack Heat Recovery Kotzebue Wind Impact on HR • Kotzebue Heat Recovery: – Water heating – District heating – Summer ice making with absorption refrigeration – ORC/stack heat recovery KEA goal of using 85% of energy in fuel. Wind-powered Electric Boilers 10 in operation 6 in construction 6 in design 16 in feasibility Nikolski Wind Example • Wind Turbine: One 65 kW Vestas • Gensets: – One- 37 kW, mechanically fuel injected – Two- 71 kW, mechanically fuel injected • • • • Avg load = 30 kW School closed Electric heaters at school, lodge and powerhouse Recent blackouts due to insufficient thermal loads to absorb peak wind output (80 kW?) Nikolski Diesel Dispatch Scenarios Electric Load Scenario Diesel Dispatch Wind Dispatch Low load 20 kW – 30 kW Maximize diesel use to reduce risk of wet stacking 37kWgenset and improve diesel efficiency Thermal purposes 30 kW – peak load (40 kW) Maximize diesel use to reduce risk of wet stacking 71kW genset and improve diesel efficiency Thermal purposes John Deere Engine Recommendations August 2004 Generator efficiency is also affected by power factor. The inductive current in the generator increases the resistive losses in the generator and lowers efficiency. The highest generator efficiency is at unity PF. A generator may run at 92% efficiency at 1.0 PF and only 90% efficiency at 0.8 PF. Tier 4 Concern • Tier 4 diesel gensets will have exhaust emission equipment that requires minimum stack temperatures for the oxidation catalyst to work. At low genset loads, those temperature requirements will be met by burning additional fuel in the stack to meet emission requirements. • AEA has requested an EPA waiver for some of the Tier 4 genset requirements Conclusions • Wind turbines have multiple impacts on the performance and economics of diesel power systems. • Wind-diesel economic analysis should include the impacts on heat recovery, diesel efficiency, power factor and quality, station power use, and line/transformer losses. • Wind energy used for heating purposes saves about 50% less fuel than when used for electrical purposes. • Diesel power system technology is changing rapidly, which makes it even more challenging to integrate wind power.