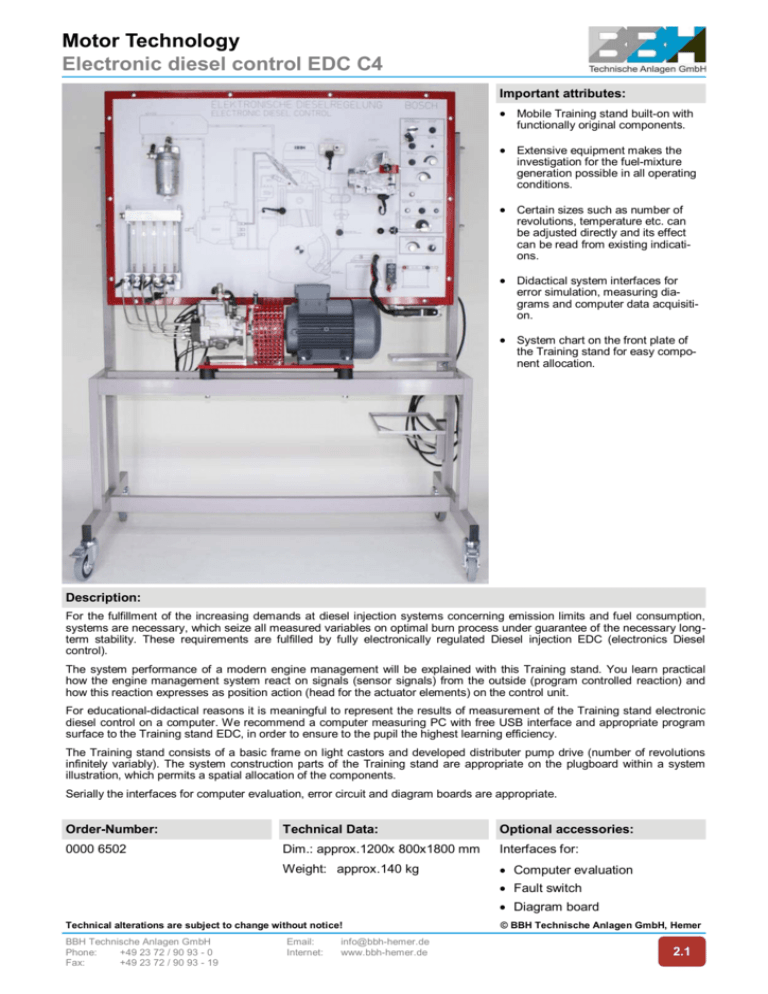

Motor Technology Electronic diesel control EDC C4

advertisement

Motor Technology Electronic diesel control EDC C4 Important attributes: Mobile Training stand built-on with functionally original components. Extensive equipment makes the investigation for the fuel-mixture generation possible in all operating conditions. Certain sizes such as number of revolutions, temperature etc. can be adjusted directly and its effect can be read from existing indications. Didactical system interfaces for error simulation, measuring diagrams and computer data acquisition. System chart on the front plate of the Training stand for easy component allocation. Description: For the fulfillment of the increasing demands at diesel injection systems concerning emission limits and fuel consumption, systems are necessary, which seize all measured variables on optimal burn process under guarantee of the necessary longterm stability. These requirements are fulfilled by fully electronically regulated Diesel injection EDC (electronics Diesel control). The system performance of a modern engine management will be explained with this Training stand. You learn practical how the engine management system react on signals (sensor signals) from the outside (program controlled reaction) and how this reaction expresses as position action (head for the actuator elements) on the control unit. For educational-didactical reasons it is meaningful to represent the results of measurement of the Training stand electronic diesel control on a computer. We recommend a computer measuring PC with free USB interface and appropriate program surface to the Training stand EDC, in order to ensure to the pupil the highest learning efficiency. The Training stand consists of a basic frame on light castors and developed distributer pump drive (number of revolutions infinitely variably). The system construction parts of the Training stand are appropriate on the plugboard within a system illustration, which permits a spatial allocation of the components. Serially the interfaces for computer evaluation, error circuit and diagram boards are appropriate. Order-Number: Technical Data: Optional accessories: 0000 6502 Dim.: approx.1200x 800x1800 mm Interfaces for: Weight: approx.140 kg Computer evaluation Fault switch Diagram board Technical alterations are subject to change without notice! BBH Technische Anlagen GmbH Phone: +49 23 72 / 90 93 - 0 Fax: +49 23 72 / 90 93 - 19 Email: Internet: info@bbh-hemer.de www.bbh-hemer.de © BBH Technische Anlagen GmbH, Hemer 2.1