Analysis of Situational Approach

advertisement

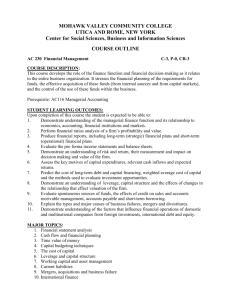

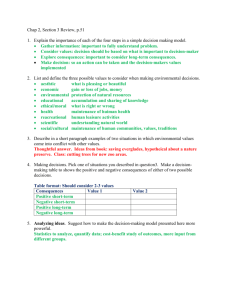

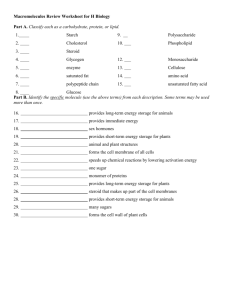

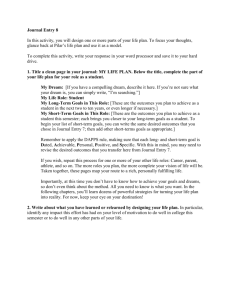

ALCON LABS Project Chiron SMU TEAM ALCON Project Overview • • • • • • Project Background Problem Description & Core Objectives Action and Approach Plan Analysis of Situational Approach Analysis and Managerial Interpretation Recommendations Project Background • October 2003: Alcon Madrid manufacturing plant closed down – Madrid’s product baseline of 170 SKUs and 12 million units were transferred to Fort Worth headquarters • Before the Madrid divesture, the Fort Worth manufacturing plant was producing 230 to 250 SKUs and 70+million units Definition of the Problem • Whitestock Lines 1 & 2 – Production inefficiency and delays – Lagging downtime • Line clearances (LC) occupy 20-30 minutes • LC occurs 4-5 per day – Loss of Capacity Core Objectives Primary objectives: • Minimizing splits – line clearances and/or QA • Maximizing utilization of fill rooms Secondary objective: • Optimizing the facility layout • Optimizing the lot size (batch) or economic order quantity levels Core Objectives - Benefits • • • • Significant cost savings Improved uptime and process efficiency Improved capacity levels Improved overall throughput speed and other technical performance measures • Reduced or eliminated inventory levels and other unnecessary costs • Minimized idleness of employees (i.e. employee output efficiency) Action & Approach Plan • Short-term perspective – Determine and measure Alcon Labs Manufacturing processes to locate source of problem associated with LC • PAT and SMED method • Long-term perspective – Converting 2-step process to inline process • ProModel: Simulation Models Analysis of Situational Approach Short-term approach • Whitestock Line 1 & 2: – Observed and measured the “splits” process steps for cycle time improvements – Recorded the sequence of repeatable activities with measurable inputs, valueadded activities, and measurable outputs Analysis of Situational Approach Short-term approach • PAT Method • SMED Method – Internal and External Setup activities – Improve cycle time or changeover/roll-over time by reorganizing and reducing setup activities as well as resources and inventory waste and rescheduling production schedules for low quantity batches while sustaining high product quality – Other benefits of setup reduction include lower cost (less inventory), better flexibility, better worker utilization, shorter lead time, increased capacity, and most importantly, less process variability Analysis of Situational Approach • SMED Method: Process Flow chart Analysis of Situational Approach • SMED Method: BENEFITS Analysis of Situational Approach Long-term approach • Converting 2-step process to inline process • Observation & Data Collection - process and layout, - setup/changeover times, - speeds and capacity, etc. - ProModel Simulation software • Assumptions • Current Process Simulation Model • New Process Simulation Model Analysis of Situational Approach Long-term approach • Variables/Functions - locations - entities - network paths - process/logic - arrivals • • product differentiation setup downtimes Analysis of Situational Approach Long-term approach: Assumptions • Setup times for each machine were calculated using an average from the statistics provided. • Simulation models are programmed to run at particular speed as opposed to individual actual speeds. • Offline filling and storage time and activities are not accounted for in the simulation model. • The proposed filler speeds and product specifics are assumed to be similar to the current equipment capabilities • When locations and resources appear to be idle, setup downtimes are in occurrence. Analysis & Managerial Interpretation Short-term Approach Alcon Operation or Process steps 1) Staging (storage) area 2) Line area: inspection 3) Changeover 4) Production 5) Finished goods area 6) Reconciliation with Materials Office Analysis & Managerial Interpretation Short-term Approach • Changeover is the main cause for low efficiency. • Steps in setup process – Preparation, after-process adjustments, checking of materials and tools – Mounting and removing blades, tools, parts – Measurements, settings, and calibrations – Trial runs and adjustments Analysis & Managerial Interpretation Short-term Approach – Calibration and Trial Runs occupy a total of 85% of total time (changeover and LC time)! Alcon Labs Setup Time Allocation 10% 5% 20% 65% Preparation Mounting Calibration Trial Runs Analysis & Managerial Interpretation Short-term Approach: • Changeover setup adjustments 1) 2) 3) 4) 5) • Labelers Cartoners Magazines Ink Jet Coder Wrapper/Packaging Adjustments are made by trial-and-error as well as intuition Analysis & Managerial Interpretation • Short-term Approach: Changeover Analysis & Managerial Interpretation Short-term Approach: • Other inefficiencies: – Incorrect Madrid Translations – Disconnected communication across divisions Analysis & Managerial Interpretation Long-term Approach: • Decreased product handling and movement • Increased flexibility and capabilities • Increased utilization, productivity levels, and capacity • Automated flex pack line • Decreased downtimes Recommendations Long-Term Solution • Recommend 1-year further analysis and research - costs - equipment - feasibility requirements - build a more accurate model - implementation Recommendations Short-Term Solution • Strongly recommend forming a changeover team of 4-5 members 1) 2) 3) 4) 5) • Labelers Cartoners Magazines Ink Jet Coder Wrapper/Packaging Update changeover team regarding production schedules for advanced preparation Recommendations Short-Term Solution • Allocate secondary space for storage – Color code • Next Raw materials – red (stop) • Current Raw Materials and Finished product – green (go) Recommendations Short-Term Solution • Streamline line clearance to a parallel process • Cross-train personnel – Require employees to perform other functions in the changeover process • Ensure prompt arrival of Bill of Materials – If items aren’t available, contingency plan should be developed • Improve coordination between Marketing, Planning, and Production divisions • Function standardization • Replace bolts with one-time tighteners! • Mark individual calibration settings for each product on each line for easy adjustments Questions? • SMU TEAM ALCON – Benjamin Luong – Chris Davis – Cuong Ngo – Cindy Nguyen – Shanta Ramdhanny