Water Quality Requirements for Fracturing

advertisement

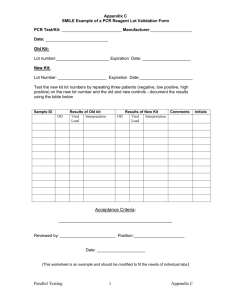

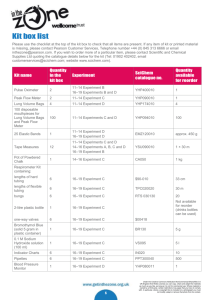

RAPID WATER QUALITY KIT FOR PRODUCED WATER REUSE: ONSHORE PRODUCTION POWER ACROSS TEXAS ENERGY CHALLENGE MAY 1, 2015 Omar Ghannoum Preston Tidwell Allana Robertson Nima Ghahremani 1 AGENDA • Introduce the idea • Portable Frac Water kit • Explain the importance • Water usage • Who will benefit • The portable frac kit • How it works • Quality Control • Bacteria • Chemistry • Conclusion 2 AN INNOVATIVE FRAC WATER TESTING KIT • Onsite testing of water to be used for Hydraulic Fracturing mixtures • Will be used as a way to screen good water from bad water • It’s cheap and quick • Will be a catalyst to new innovations in oil field water usage 3 CURRENT WATER PROBLEMS IN TEXAS • A typical shale well uses 5M gallons of water for hydraulic fracturing • 7 Billion bbls Produced water per year in the Eagle Ford formation (Adham 2014, USDOE) • 40% of water used for fracing comes back up to the surface • Handling water is expensive • Fresh water costs: $0.88-6.05/bbl Disposal costs: $1.13-$10.75/bbl Frac Pond (Energy Corp. of America) Water management accounts for up to 10% of well costs (IHS) Important chemistries in produced water prevent us from using it directly due to compatibility issues (Blauch 2010) 4 WATER IN HYDRAULIC FRACTURING FLUIDS • • Slick Water • Sand + Water + Acid • Pumped at extremely high rates (60-100 BPM) to achieve fracture Cross Linker Gel • Sand + Water + Acid + Guar Gel • Uses high viscosity and density to achieve fractures 5 WHAT IS PRESENTLY DONE Currently produced water is: • Re-injected into reservoir to maintain pressure, 56% • Pumped into disposal wells, 39% • A small percentage is cleaned and recycled, about, 3% Cleaned using: • Coagulation, hydrocyclones, coalescers, flotation, and micro, ultra, nano, and reverse osmosis filtration systems Drillingcontractor.org 6 (Al-Maamari 2014); (USDOE); (EOR) WHO CAN BENEFIT FROM THE KIT? • • Service companies (Halliburton, Schlumberger, NOV) • These companies are responsible for the quality of hydraulic fracturing job • Can use the kit to help them cut costs and deliver a better product • Lower oil prices means lower margins, and every bit counts Operators • Lower water handling costs • Can make locals happy because of less water usage • Wastewater management is the primary driver of costs 7 RAPID CHEMISTRY KIT FOR COMPATIBILITY TESTING Suggested Levels Suggested Levels Boron 5 mg/L pH 4-9 Barium 40 mg/L Iron 70 mg/L Bacteria 2500 ATP Sulfate 400 mg/L Calcium 500 mg/L Total Suspended Solids 5000 mg/L Chloride 30,000 mg/L Acidity 500 mg/L Chemical Tested Chemical Tested • < 8 = Good • 4-8 = Some filtration/mixing needed • > 4 = Extensive filtration needed 8 Photo from LaMotte Corp. WHY IS WATER CHEMISTRY IMPORTANT ? • Interference with friction reducers • Chlorides (+) • Calcium (+) • Magnesium(+) • Bacteria • Clogs pores • TSS/TDS •Creates friction •Scaling • Hydration of Crosslinker •Boron •Iron •Sulfate 9 WATER REUSE IN COMPLETION ACTIVITIES Flow Back Cleaned Flow back fluid and recycled fluid from Baaken: photo by SIONIX • Flow Back or Produced Water contains high concentrations of a variety of ions • Kit can determine water compatibility for operations • Pre and post cleaning chemical levels 10 SCALING TENDENCIES 1. Scaling: Oil and gas recovery reduction due to the formation of typical scales such as sulfate salts of calcium, strontium, and barium. Example Scaling Problem: Assumptions: Flowback water has 20 mg/L of Ba2+ Groundwater has 200 mg/L of SO42Temperature = 25 °C (at surface) 11 IMPORTANCE: CORROSION MANAGEMENT Chemical Corrosion /Scaling Equipment Failures & Environmental Incidents Microbial Influenced Corrosion 12 Duncan, K.E, Perez-Ibarra, B.M., Jenneman, G., Harris, J.B., Webb, R., Sublette,K. 2013. The effect of corrosion inhibitors on microbial communities associated with corrosion in a model flow cell system. Applied Microbiology and Biotechnology 98:907-918. WHY IS WATER BIOLOGY IMPORTANT? Microbes in the water column: Planktonic Microbes attached to surface: Sessile Attachment Cell-to-cell adhesion Growth Matures & Releases 13 Davis Lab: http://www.binghamton.edu/biology/faculty/davies/research.htm Baldwin, P., Mulliniks, B., 2015. Chemical-Free Bacteria Neutralization and In-Field Testing. (emailed copy prior to publication at a conference). 9 MAJOR MICROBIAL INFLUENCED CORROSION GROUPS (SRB) Sulfate-reducing (TRB) Thiosulfate-reducing (NRB) Nitrate-reducing (APB) Acid-producing (IRB) Iron-reducing Methanogens (SuRB) Sulfite-producing (SPB) Slime-producing (IOB) Iron-oxidizing Note: (SPB) also classified as (EPS) Extra 14 polymeric substance producing Sherman, S., Brownlee, D., kakadjian, SPE,S., Luft, B., Trican Well Service Ltd. 2014. Microbial Influenced Corrosion of Coil Tubing Milling Strings in the Eagle Ford Shale. No. IPTC-18032-MS. International Petroleum Technology Conference, Kuala Lumpur, Malaysia (2014). MOBILE MONITORING OPTIONS Molecular Technology Ease of Use Testing Time (min) Portability Accuracy Microbial Activity Tested Cost per Test ATP LuminUltra Easy 5 Very Good Good All (viable & nonviable) $7 Bactiquant Moderate 11 Very Good Good All (viable only) $20 QuickChek SRB Moderate 10 Very Good OK SRB (viable & nonviable) $14 Rapid-B Flow Cytometer Easy 3 Benchtop Based Very Good All (viable only) $20 Bug Bottles Easy 5-7 days Benchtop Based OK Specific to Media (viable only) $0.60 15 http://www.hach.com/quick.search-quick.search.jsa?keywords=ATP+LuminUltra http://www.modernwater.com/monitoring/by-industry/oil-and-gas (Victor Pena Sales Account Manager) http://www.mycometer.com/ http://www.biotechnologysolutions.com/ http://www.pcbdservices.com/technology/oil-and-gas.php MMM’S IN USE AT ENCANA FIELD SITE, PERMIAN BASIN Rapid-B Flow Cytometer Bactiquant ATP LuminUltra 16 Industry Standard Bug Bottles COMPARISON BETWEEN KIT AND LAB ANALYSIS Concentration (mg/L) 100,000 10,000 1,000 100 10 1 Chloride Iron Alkalinity Calcium Conductivity, mS/cm Turbidity, FAU TSS, lab pH Acidity Note: Boron, Barium and Sulfate were below MDL of the field kit; TDS was above the detection 17 limit (Results of water chemistry analyses for “Earlyne SWD 2/25/15” performed with field water test kit) LETS REVIEW: RAPID CHEMISTRY KIT FOR COMPATIBILITY TESTING The main purpose of our kit is to: •Only takes 1 hour to complete all the tests •Identify ‘good’ and ‘bad’ water on site •Less than 5% error compared to certified lab •Provide a reasonable estimate of contamination levels •Less than $20 to complete all tests As a result of using our kit, you should see a reduction in: •Less down time on rig site •Fresh water needed for completion activities •Expenses related to water purchase •Tensions between local communities and production companies Time Money $$ 18 ACKNOWLEDGMENT Michael Irlbeck Mika Bradford & The Vivione FieldTeam Jennifer Fichter Ecolyse Field Scientists David Burnett & The GPRI Team Dr. Lee Clapp; Environmental Engineering Dr. Lucy Camacho; Environmental Engineering Research Partnership to Secure Energy for America 19 QUESTIONS? 20