Activity-Based Management

advertisement

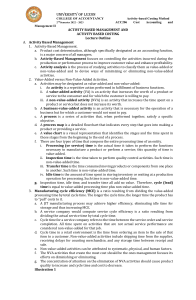

Activity-Based Management Chapter 5 Activity-based costing Allocation process Does not reduce or create costs Does determine the cost to perform activities Forms the basis for process improvement Activity-based management Activity-based management Evaluates the cost and value of activities to identify opportunities for improvement High or low value to the customer? Enhance value-added activities Reduce non-value-added activities Value- vs. non-value-added Would the customer willingly pay for the cost of the activity? Would the customer encourage doing more of the activity? Does the activity help the organization reach its goals? Value-added vs. non-value-added activities Activity Material handling Set-up Assembly Testing and inspection Rework Packaging Breaks and meetings Value-added? No No Yes Maybe No Maybe No Value-added vs. non-value-added activities Determination is often subjective Some are obvious Others may be necessary, but do not add value to the customer Use rating scale to categorize Too much or too little detail can hurt Should use a team-based approach Must consider interactions Steps in the ABM process Activity analysis Value-adding? Customer’s viewpoint Necessary evil Non-value-adding Cost Steps in the ABM process Identify opportunities for improvement Low value-adding Willie Sutton rule Identify the root cause of the problem “The 5 why’s” Fix the problem, not treat the symptoms Steps in the ABM process Estimate cost and cost savings What will the changes cost? How much will they save? Make the changes Evaluate results Are expected results achieved? Repeat the process ABC/ABM implementation considerations Management commitment Scope of project Determines resources needed Resources Personnel Time Technology ABC/ABM implementation considerations Organizational culture Acceptance of change Willingness to use the information Open communication Sharing ideas Rumor control Teamwork Cost of unused capacity CAM-I capacity model Productive capacity Output of saleable product Non-productive capacity Capacity lost to non-productive activities Set-ups, maintenance, defects, delays, etc. Idle capacity Unused capacity Weekends, vacations, lack of orders, etc. Cost of unused capacity Identifying cost of unused capacity Resources supplied – resources used Identifies opportunities for improvement Reduce capacity Increase output without incurring more of the cost Some unused capacity is inevitable and good