Exploring Culture Essay

advertisement

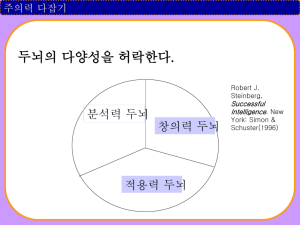

Running Head: Exploring Culture Essay Exploring Culture Essay Johnathan Arthur University of Kentucky 1 Exploring Culture Essay 2 Abstract Toyota Motor Manufacturing Kentucky is not only a successful branch of the Toyota chain, but it is a culture. It’s made up of a variety of people with different skills all trying to work toward larger goals. As they work together they must show respect for the law, others, the environment, customers, and their subordinates. Because of the size of the plant there is a large-scale hierarchy system based on Japanese management techniques. Each level must be able to teach and act out the skills that the next level under them will use. All employees must be able to cooperate to complete whatever task they are assigned. Cooperation on this large of a scale requires several means of communication and strict schedules. Overall the culture in TMMK focuses on teamwork and cooperation between every level of management and in every job. A way of thinking called Kaizen is used as the structure for their ideas. Toyota also helps its surrounding community with its environmental and volunteer philosophies. Exploring Culture Essay 3 Exploring Culture Essay In the small town of Georgetown, Kentucky, there stands the largest Toyota factory in North America. According to Anne Harris, “The Toyota plant at Georgetown, Kentucky is the Japanese manufacturer’s flagship facility in the United States” (2007). On the outside it may look like any other factory with ordinary employees, but with its complex hierarchy, values, and its use of kaizen (good change) and the Just-In-Time System, Toyota Motor Manufacturing of Kentucky is a fine example of a cooperative working culture. Each employee works with others to make sure that they make quality vehicles, satisfy customers, and improve their community around Kentucky. To explain the behaviors and attitude of the ideal Toyota employee, there are two basic structures. Toyota’s Corporate Philosophy involving respect for the law, respect for others, respect for the natural environment, meeting customer expectations, and respect for employees. To help employees follow this philosophy, Toyota has created a set of five values including encouraging professional excellence, welcoming new challenges, Toyota’s Five Values encouraging teamwork, putting customers first, and a global perspective. Exploring Culture Essay 4 Although it’s hard to picture any human following a set of standards perfectly, Toyota employees take the challenge to do so. These values turn them into a community of problem solvers that work together to fix and develop machines and systems. These tactics force them to share their ideas and expertise with each other to make sure any given task is completed correctly. Communication is an essential factor in a Toyota employee’s daily activities. In each assignment they will be either working with someone or communicating their results to someone looking over the assignment. According to Johnathan Risner, a Group leader at TMMK, the tone used while speaking to any person in the plant can change depending on the situation. “So usually in a management position, people above me need to know information. They need to know direct information. So usually, when I’m talking to them about something work related, it’s usually very assertive, on point and what they need to know. If there’s any questions after, they can ask me after, but I try to give them information as quickly as possible.” (Johnathan Risner, personal communication, September 25, 2014). Communication won’t always be direct. When a shift ends, a leader from the shift before will have to record any messages regarding significant events such as complaints from customers or safety issues. Also, not all communication in the plant is purely work. Getting to know coworkers can help strengthen teamwork and trust. Some employees in management positions try to get to know their employees to better understand their work habits. When mistakes are made in the plant, it us up to the employee to communicate to their manager, or other employees on their level, about how they are going to fix the problem. John Exploring Culture Essay 5 Arthur, a team leader at TMMK stated, “Well, you know, normally I will… directly ask them what happened. Once we figure out what the root cause of the problem is we will fix it. Together we’ll try to fix it.” (John Arthur, personal communication, September 25 2014). The most important person for a Toyota employee to communicate with is the person above them. They can provide the manpower, or brainpower, to help solve the problem. In the Toyota Code of Conduct (2006) it is stated, “As valuable contributors to TOYOTA, we should each also endeavor to fully utilize our capabilities and to put forth our best efforts in all matters in order to strengthen and build TOYOTA’s business performance globally.” (p. 8) Despite being in the U.S. TMMK developed most of its structure from its Japanese roots. Because of Japanese management influence the management hierarchy consists of thirteen positions ranging from President to Team Members. Group leaders and team leaders are responsible for managing all production related activities. Group leaders have management over about thirty individuals, including team leaders, whom have about seven Diagram of Japanese Toyota Management Hierarchy individuals to look after. Team leaders are different than bosses in other industries in the fact that they can perform every job of the people in their team, and are an essential part of keeping the team at full power each day. They are also required to be able to teach their skills to newcomers. Exploring Culture Essay 6 This hierarchy structure puts emphasis on the word team. No matter what happens in the factory, it involves a team, and team managers. Even the president is the head of a team of vice presidents. In Toyota’s Corporate Philosophy, they encourage cooperation because it helps employees realize their full potential. An element used to encourage this multilayered culture is kaizen. Kaizen is a method to help companies improve continuously if done correctly. (Smadi, 2009, p. 203-211). Everyone works together to keep finding new ways to better their establishment. Robert Maurer (2013) explains it like this: Kaizen has two ingredients. One is to train each employee to come to work each day looking for ways to improve the process and/or the product. The second ingredient is that all improvements have one purpose in mind, which is to serve the customer. (p. 1) An example of this way of operating is when a line worker notices a mistake on a vehicle. Even the smallest dent in the metal can cause problems down the road, so employees are trained to stop the building process until the problem is either fixed or removed. The cost of stopping the line at that moment will not only protect customers but also save them from wasting any more supplies on that specific vehicle. Small investments like this help Toyota save money to invest in better equipment and higher salaries for their employees. As stated in the Toyota Code of Conduct (2006), “TOYOTA endeavors to improve its business performance in order to make it possible to provide equal employment opportunities and to maintain fair and stable working conditions.” In return, the employees help the plant improve even more. Exploring Culture Essay 7 TMMK employees are also trying to improve the world outside of the factory. According to the Toyota Code of Conduct, Toyota itself is thought of as a member of the community, and because of this it must fulfill its duties as a citizen. It is stated in Toyota Code of Conduct (2006): Through its business, TOYOTA creates close relationships with society and its stakeholders (customers, shareholders, local communities, etc.). Based on the basic understanding that “as a member of society, the company engages in business that contributes to society”, TOYOTA operates its business in an open and fair manner. (p. 15). Toyota’s Volunteers In Place (VIP) program helps put employees out in the community to help a variety of charities of their choice. As explained in Toyota Volunteers in Place Program, For many of TMMK team members volunteering is a way of life — whether it's volunteering to build a Habitat House, being a Big Brother or Big Sister, or a scout master for Boy Scouts or Girl Scouts, many team members at TMMK are actively involved in their communities. (“Volunteers In Place Program,” n.d., para. 2). Toyota makes sure to reward these employees by honoring them at a recognition dinner. On top of this, the charity of their choice is given money based on the amount of hours that employee, or group of employees, has worked. Through this, charities have been given over $50,000 and tens of thousands of volunteer hours. “Through volunteerism, TMMK and its team members work together to make their communities stronger, healthier and a better place to live” (“Volunteers IN Place Program,” n.d., para. 6). Exploring Culture Essay 8 Knowing that they helped an organization, both physically and economically, can keep Toyota employees feeling like they are making a difference to other members of their community. On top of this, members of the outer community will gain more respect for Toyota and the members of its inner community. Toyota has also reached out to other organizations in the community, such as the Scott County Board of Education, the University of Kentucky, and the Kentucky Historical Society. Instead of paying property taxes, Toyota pays the Scott County Board of Education the amount of money equal to its property taxes each year. (“Corporate Citizenship,” n.d., para. 7). The University of Kentucky was gifted $1 million in 1989 to help increase the amount of books in its libraries. (“Corporate Citizenship,” n.d. para. 9). Another $1 million was gifted to the Kentucky Historical Society. (“Corporate Citizenship,” n.d., para. 12). TMMK helps out the community with more than money and volunteers. They run a daycare center and a gym for employees and family members. They also provide traffic safety education and disaster and crime prevention activities. Also, in the case of an actual disaster, Toyota, will help other communities to recover. (Toyota Code of Conduct, 2006, p. 18). In terms of environment, TMMK has adopted the EARTH CARE policy, which is a set of goals for Toyota employees to follow to both be aware of and protect the environment. (“Toyota And The Environment,” n.d., para. 2). TMMK employees are expected to use what they need and only what they need. They follow the Just-In-Time philosophy, which means “making ‘only what is needed, when it is needed, and in the amount needed.’” (“Toyota Production System,” n.d., para. 1). This system Exploring Culture Essay 9 requires employees to plan ahead before starting any project, so that they can complete it with the least amount of waste possible. The Toyota plant in Georgetown hires employees no matter what ethnicity. The Toyota Code of Conduct (2006) states that it will not discriminate against its employees or take away their rights (p. 8). The employees of TMMK are considered to be some of the most diverse of 1,000 top companies in the United States. Not only was it rated among the top 40 Best Companies for Diversity by Black Enterprise (News at TMMK, 2007), but it is also included among DiversityInc.’s Top 50 Companies for Diversity, the Human Rights Campaign "Best Places to Work Corporate Equality Index”; inducted into the Billion Dollar Roundtable for spending 41 billion annually on supplies from ethnic and women-owned vendors; and has won the “Corporation of the Year” award and “Distinguished Supplier Diversity Award” from the National Minority Supplier Development Council (NMSDC) and the Minority Business Development Agency (MBDA). (Toyota Named Among Best, 2007). Kaizen, the five values, advanced hierarchy system, waste management system, and environmental philosophy helps make Toyota its own culture that separates itself from the slave labor of the stereotypical factory. TMMK goes far beyond what any business is expected to do for its community and its employees. Its employees of every ethnicity and personality work together, both in the factory and around the community, to make their mass production system run, and help the world in creating a successful and productive place to live. Over all, TMMK is a community within a community. Exploring Culture Essay 10 Bibliography Corporate Philosophy. (2014). In Toyota Industries Corporation. Retrieved from http://www.toyota-industries.com/corporateinfo/philosophy/ [Diagram of Japanese Toyota Management Hierarchy]. Retrieved September 10, 2014 from http://www.slideshare.net/LeanLeadership/toyota-operational-leadership-structure-16489590 Harris, A. A. (2007). Made in the USA [automobile industry]. Manufacturing Engineer, 86(1), 14-19. doi:10.1049/me:20070103 [Image of Toyota’s Five Values]. Retrieved September 10, 2014 from http://www.toyotaindustries.com/corporateinfo/philosophy/ Jeffery, L. (2005). Toyota Way Fieldbook. New York, NY: McGraw-Hill. Robert, M. (2013). Building a Quality Culture One Small Step at a Time. Journal for Quality & Participation, 35(4), 8-11. Smadi, S. A. (2009). Kaizen strategy and the drive for competitiveness: challenges and opportunities [Abstract]. Competitiveness Review, 19(3), 203-211. Terry, B. (1996). Team Toyota. Albany, NY. State University of New York Press. Toyota And The Environment. (n.d.). Toyota And The Environment. Retrieved from http://www.toyotageorgetown.com/envirodex.asp Toyota Code of Conduct. (2006). Toyota Code of Conduct. (N.P.) Toyota Motor Corporation. Exploring Culture Essay 11 Toyota Named Among Best. (2007). Toyota Named Among Best Companies for Diversity by Black Enterprise. Retreived from http://www.toyotageorgetown.com/detailnews.asp?PRID=388 Volunteers In Place. (n.d.). Toyota Volunteers in Place Program. Retrieved from http://www.toyotageorgetown.com/comm1.asp