Starch - Central Washington University

advertisement

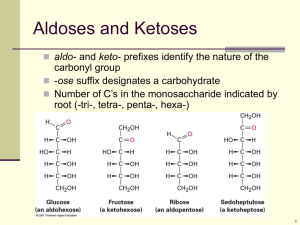

Starch Megan Erickson Central Washington University What is it? Complex carbohydrate made up of two components Components: – Amylose – Amylopectin Properties depend on amounts of the components Where is it found? Roots/Tubers – Potato – Arrowroot – Tapioca Cereal – – – – – Corn Waxy corn Wheat Rice Waxy rice Amylose Linear component of starch Contains 1,4alpha-glucosidic bonds Molecular weight: less than 0.5 million Can form coils which will trap iodine and turn blue Amylopectin Branched component of starch Contains 1,4-alphaglucosidic as well as 1,6-alpha-glucosidic bonds Molecular weight: 50-500 million Limited coiling causes purplish-red color when iodine added Amylose vs. Amylopectin Starches usually contain more amylopectin than amylose Generally roots/tubers contain more amylopectin than cereals Roots/Tubers: 80% amylopectin Cereals: 75% amylopectin Waxy corn and rice contain virtually all amylopectin Starch Composition Starch Tapioca Potato Wheat Corn Waxy corn Hi amylose Rice % amylose % amylopectin 17% 83% ~20% ~80% 25-26% ~75% 24-28% ~75 ~0% ~100% ~ 75% ~ 25% 22% 78% Starch Granule Made in the cytoplasm of plant cells Amylopectin forms in concentric circles with amyose dispersed in between Held together by hydrogen bonds The granule swells when heated in water Starch Granule Functions Gelatinization – Structure in baked products – Thickener in sauces, soups, and dressings Dextrinization Gelation – Pie filling Gelatinization When starch is heated in water Hydrogen bonds break, allowing water to enter the granule and the granule swells Amylose migrates out of the granule H-bonding between water and amylopectin increases Reduced free water changes the viscosity of the starch mixture, thickening it Gelatinization and Temperature Gradually thicken with temperature Can be heated to 100oC without much granule rupture If held at 95oC will implode and lose viscosity Gelatinization and Type of Starch Best thickening ability: potato starch Worst thickening ability: wheat starch More amylopectin=more translucent=more stringy Viscosity and Type of Starch Gelatinization and Sugar Used together in pie fillings and puddings Sugar competes with the starch for water so less water available for gelatinization Delays gelatinization and decreases viscosity Increases gelatinization temperature The more sugar added, the longer the delay Disaccharides have a stronger effect than monosaccharides Gelatinization and Acid Used together in fruit pie fillings, specifically lemon fillings Acid breaks down starch molecules so the paste is thinner Decreases viscosity Acid effect can be minimized by adding after gelatinization or heating rapidly Gelation As a starch paste cools, a gel is formed Free amylose molecules lose energy as the temperature decreases and form hydrogen bonds The bonds create a network that holds the swelled granules in place Gelation and Starch Source The more amylopectin (less amylose), the softer the gel Potato starch=high amylopectin=good thickening agent=soft gel Corn starch=less amylopectin=less effective thickening agent=strong gel Gelation and Other Effects Heating – Moderate temperature and rate of heating – Enough amylose needs to be released from the granule without the granule bursting Agitation – Agitation during cooling disrupts amylose network – Should mix flavorings immediately after removing from heat Gelation and Other Effects Sugar – Decreases gelatinization and amylose release – Softer gel Acid – Decreases gelatinization by hydrolysis of granules – Softer gel Aging Gels Syneresis – Loss of water from a gel – Amylose molecules pull together, squeezing water out Retrogradation – Realignment of amylose molecules – Hydrogen bonds break and reform into more orderly crystals – Can by reversed by gently heating – Examples: refrigerated pudding, stale bread Dextrinization When starch is heated without water A higher temperature is reached than with water Bonds break throughout the starch forming dextrins Genetically-modified Starches Waxy starch – High in amylopectin – Used in fruit pies because thickens well, but does not gel well – Have good freeze-thaw stability High amylose starch – Amylose creates strong bonds to form strong gels – Used in edible films to coat food How to compare starches? Line spread test: – Measures thickening power – Poor heated starch into cylinder, lift cylinder and measure spread after specified time using concentric circles Universal Texture Analyzer: – Measures gel strength Percent sag: – Measures gel strength – Measure molded gel height and compare to unmolded gel height – Stronger gel=small % sag, weaker gel=large % sag Modified Starches Physically or chemically modifying native starches Are used for specific applications in the food industry, Why? Native starches have undesirable qualities: – Poor processing tolerance to heat, shear and acid – Poor textures – Do not store, hold, and freeze/thaw well Pre-gelatinized Starches Use: – Instant pudding Dehydrated gelatinized starch – – – – Heated so granule swells and then dehydrated Swells when water added, no heat necessary Decreases preparation time Physical change Thin-Boiling Starches Use: – Pass freely through pipes Acid-hydrolyzed starch – Hydrolyzes 1,6-alpha-glucosidic bonds – Amylopectin in smaller pieces – Decreases thickening power, but makes a strong gel because hydrogen bonds form more readily Cross-linked Starch Use: – Increases storage time because of reduced retrogradation – More stable at high temperature, with agitation, and with acid addition – Salad dressings, baby foods, pie fillings Cross-linked starch molecules – Alter hydroxyl ends under alkaline conditions by acetic anhydride, succinic anhydride, or ethylene oxide Viscosity and Cross-linked Starches Resistant Starch Small intestine is unable to digest, limited digestion in large intestine Classifications – – – – RS1: RS2: RS3: RS4: trapped in cells (seeds/legumes) native starch (raw potatoes, bananas, waxy maize) crystalline, non-granular starch (cooked potatoes) chemically modified Can contribute fiber to food without the fat that bran has Takes up less water than other fiber, making dough less sticky Smooth even texture Less than 3 cal/g