Nikon Case - s3.amazonaws.com

advertisement

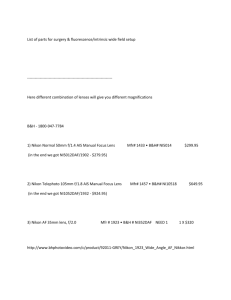

Nikon and its Supply Chain Innovation INTRODUCTION A supply chain is a system to move a product or service from suppliers to customers. An effective supply chain enables companies to cut cost, renovate inventory, and delight customers, which help companies develop a competitive advantage in today’s highly competitive market. As a forward-looking company, Nikon Corporation has realized the importance to develop a flexible and effective distribution network. While developing a solid corporate foundation to better adapt changes and seize business opportunities, Nikon put great efforts to innovate its supply chain to meet and exceed customer expectations. BACKGROUND Nikon Corporation is a Japanese multinational corporation specializing in optics and imaging products since 1917. With its corporate philosophy, “Trustworthiness and Creativity,” Nikon contributes heavily to the study of light. By the 20th century, Nikon had expanded its market internationally, including United States, Switzerland, Netherlands, Canada, U.K., Korea, Singapore, China and many other major countries. As it becomes more global, Nikon enacted a new corporate vision as “Our Aspirations – Meeting needs. Exceeding expectations.”1 In 2011, Nikon was recovering from damages caused by the Great East Japan Earthquake and restoring manufacturing subsidiary damaged by severe flooding. The adversities provided 1 http://www.nikon.com/about/info/philosophy/index.htm This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. Nikon an insight to build a solid corporate foundation through innovating its business processes. This solid foundation may enable Nikon to execute accurately and respond quickly to changes. To achieve success, Nikon needs more than its high-quality products. To meet and exceed customer expectations, Nikon also needs an effective and flexible distribution network to deliver its advanced products to the market. This distribution network must also be able to adapt to the changes and seize business opportunities. In addition, Nikon works on improving risk control to maintain a stable supply of products and quality. SALES FIGURES: GEOGRAPHY2 For 2011, Nikon’s net sales were consisted of 14.33% of Japanese market, 26.77% of USA market, 22.86% of European market, 10.92% of Chinese market and 25.12% of other markets. For the year ended March 31, 2012, Nikon’s net sales were consisted of 14.2% of Japanese market, 24.1% of USA market, 24.6% of European market, 13.7% of Chinese market and 23.3% of other markets. SALES FIGURES: PRODUCTS For the fiscal year ended on March 31, 2012, Nikon’s net sales were consisted of 63.9% of imaging products, 27% of precision equipment and 6.1% of instruments. All the graphs and charts of this section are downloaded from Nikon’s 2012 Annual Report. http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf 2 This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. The imaging products segment provides “products and services of imaging products and it peripheral domain, like digital SLR cameras, compact digital cameras and interchangeable camera lenses.”3 For this segment, technical advancement for digital cameras is rapid and requires constant investment. The precision equipment business provides products and services of IC and LCD steppers and scanners. In IC steppers and scanners, Nikon expanded sales of ArF immersion scanners. In LCD steppers and scanners, small to medium-sized high-definition panels performed well in sales, leading to increases in unit sales. (ArF Immersion Scanner NSR-S621D) 3 http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. The instruments business provides products and services of microscopes, measuring instruments and inspection equipment. This segment will continue to develop bioscience field, focus on live cell research, and expand sales of non-contact three-dimensional measurement systems.4 PROCUREMENT As stated in Nikon’s 2011 annual report, the highest priority in Nikon Imaging Company currently is to strengthen procurement capabilities. Nikon’s objective is to “pursue the greatest possible production-cost reductions.” To achieve this objective, Nikon established a specialist organizational unit to increase the efficiency of intense procurement negotiations and reduce the procurement process costs.5 4 http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf 5 http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2011/11annual_e06.pdf This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. To realize high levels of customer satisfaction, Nikon developed a Basic Procurement Policy, CSR Procurement and Green Procurement. Under the Basic Procurement Policy, Nikon shall conduct sound corporate activities, while complying with the laws, norms and social responsibilities. Nikon established an open-door procurement that it purchases goods and services from global suppliers. Based on open-door procurement, Nikon selects top suppliers from fair and free competition. In addition, Nikon insists building partnership relationships with suppliers with trust and to prosper together. Finally, Nikon adopts green procurement with consideration of environment.6 Nikon developed the CSR procurement to fulfill its social responsibilities. Nikon requests each stores to comply with safety and quality standards and environment preservation. Each store should enforce norms related to human rights and labor. Nikon also recommends stores to conduct voluntary activities. Lastly, Nikon asks stores to prevent the leakage of confidential information of customers and third parties. 7 Nikon also established the Green Procurement. Basic Green Procurement policy includes giving priority to 1) purchase of items that were produced with environmental consideration and 2) suppliers who conserves the environment.8 SUPPLIERS Nikon works hard to maintain close relationships with suppliers while ensuring stable procurement. In some areas, Nikon is dependent on specific suppliers to provide raw materials, core components, finished goods manufactured under contract, and other products, which is a weakness. To improve, Nikon is trying to build a flexible system with alternative suppliers and 6 http://www.nikon.com/about/info/procurement/policy.htm http://www.nikon.com/about/info/procurement/csr.htm 8 http://www.nikon.com/about/info/procurement/green.htm 7 This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. production locations in case of natural disasters, such as flooding and earthquake in 2010, and others hazards. By March 31, 2012, Nikon has been working with several suppliers all over the world. In Europe, Nikon Holdings Europe B.V., one of Nikon’s Finance & Accounting Headquarter, is in charge of centralized supply. There are also many centers and division companies being responsible for importing, selling, and serving of cameras and instruments. In Asia-Oceania and the Middle East, there is no centralized supply. Nikon Holdings Hong Kong Limited is the Headquarter there. Several imaging and equipment segment divisions are responsible for importing, selling and serving of cameras and equipment. In addition, Nikon’s Corporate Planning, Information System and Business Administration Headquarters are all located in Japan. Moreover, Nikon American Inc. is responsible for centralized supply in the USA.9 MANUFACTURERS - Precision Equipment Company Nikon’s production system of precision equipment consists of production plants and production subsidiaries. Production subsidiaries in Japan manufacture steppers and scanners as well as other relative devices. In 2009, Nikon recognized the difficulty to maintain its current production system, and integrated its 4 subsidiaries into 2. With this integration, Nikon adjusted its workforce. Currently, Nikon’s Yokohama Plant and Zao Nikon Co. (subsidiary) are in charge of LCD Steppers and Scanners. Nikon’s Kumagaya Plant and Tochigi Precision Co., Ltd (subsidiary) are responsible for IC Steppers and Scanners. All of these manufacturing factories are located in Japan. 9 http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. There is no manufacture of precision equipment products besides Japan. However, there are many subsidiary companies being responsible for importing, selling, maintenance and servicing of IC/LCD Steppers & Scanners in Europe, USA and Asia.10 Imaging Company Many of Nikon’s digital SLR cameras and interchangeable lenses had been manufactured in Nikon Thailand Co., Ltd. After the flooding, in an effort to restore supply chain and manufacturing operations, Nikon began alternative production at Thai partner factories while restoring Nikon Thailand Co., Ltd. Other manufacturing factories of imaging products are located in China. Nikon Imaging (China) Co., Ltd is a manufacture of digital cameras and digital camera components. Guang Dong and Hang Zhou Nikon Camera Co., Ltd are responsible for manufacturing digital camera components. In Japan, Tochigi Nikon Corporation manufactures interchangeable leases and optical lenses. Sendai Nikon Corporation manufactures cameras.11 Instrument Company Instrument products are produced in factories all over the world. Nikon Metrology NV is a European manufacture of microscopes, instruments and metrology. In Asia-Oceania and the Middle East, Nanjing Nikon Jiangnan Optical Instrument Co., Ltd. is responsible for manufacturing of microscopes and objective lenses for microscopes. In Japan, Kurobane Nikon Co., Ltd. and Nikon-Trimble Co., Ltd. are responsible for instruments manufacturing. There is no manufacturing factory in the Americas but only centers for importing, selling and servicing.12 10 http://www.nikon.com/news/2009/0526_01.htm http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf 12 http://www.nikon.com/about/ir/ir_library/ar/pdf/ar2012/12annual_e.pdf 11 This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. PRODUCT DEVELOPMENT Another important aspect when competing against competition is to shorten the product development lead times. Nikon believes that it is essential to thoroughly clarify all processes related to product development, and review and reform these processes. DISTRIBUTION Nikon had recognized the necessity to design and implement a new distribution strategy to improve its customer service. This new distribution strategy must be able to deliver leading products to customers timely and efficiently. According to Arnold Kamen, Nikon’s Vice President of Operation and Customer Service, “having the ability – and visibility – to predict how much merchandise is available and when it can be distributed makes the difference in staying ahead of customers’ needs”.13 With the help of UPS Supply Chain Solution from 2005, Nikon developed its synchronized supply chain strategy. This strategy significantly shortened Nikon’s supply chain and improved distribution to markets and customers. In the meanwhile, with the help of professional distributor, Nikon could focus more on developing new products and improving product qualities. UPS Supply Chain Solutions 13 http://www.ups-scs.com/solutions/case_studies/cs_nikon.pdf This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. UPS Supply Chain Solutions is aimed to help companies build competitive advantages. Its main areas of service include transportation and freight, contract logistics, customs brokerage, consulting services, and industry solutions. Transportation and freight offers companies a single source to manage global transportation and freight. Contract logistics provide business end-toend global solutions and IT systems. Global trade helps companies figure out complex trade agreements and international regulations. Consulting services team offers real-world strategic direction and guidance to large companies and government to align supply chain processes with business strategies. Industry solutions help companies understand needs and challenges companies face in specific industries.14 Synchronized Supply Chain Strategy As a global company, Nikon competes for product leadership, and its supply chain is one of the essential elements of its competitive advantage. The key to success is whether the supply chain is able to adapt customer needs and market changes. Synchronized Supply Chain Strategy is aimed to deliver products to the right place and at the right time consistently. Significant benefits to implement a synchronized value chain strategy include higher customer-service levels, reduced supply chain costs, leaner inventories, and faster time to market and response to market pricing pressures.15 Nikon’s manufacturing centers are primarily located in Asia, including Korea, Japan and Indonesia. The Synchronized Supply Chain Strategy starts from UPS managing Nikon’s freight, through air and ocean, directly to Louisville and Kentucky. Louisville and Kentucky are the allpoint connection for UPS’s global operations and the main Center of UPS Supply Chain Solutions. Here, merchandise can be packaged to accessories such as batteries and chargers, or to 14 15 http://www.ups-scs.com/about/index.html http://www.gexso.com/material/Synchronized_Value_Chain.pdf This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. in-store display specifications. Finally, the packages are distributed to retailers across the United States, or exported to Latin America or the Caribbean retail outlets and distributors.16 This end-to-end distribution is all managed by UPS Supply Chain Solutions through stop keeping unit (SKU)-level visibility and IT system. SKU is a number or string of alpha and numeric characters that uniquely identifies a product. Many companies and retailers use their own SKU numbers to label products so they can track their inventory using their own database system.17 In addition, UPS delivers products using UPS’s worldwide transportation services and provides Nikon advance shipment notifications. Nikon has seen the results of its innovation. Supply chain performance and customer service have significantly improved. Products leaving Nikon’s manufacturing facilities in Asia can now be on a retailer’s shelf in as few as two days. While in transition, Nikon is now able to inform retailers about delivery times and adjust them as needed. Just as Arnold Kamen expected, Nikon now has the visibility of product distribution and ability to adjust product availability based on needs. As a result, Nikon has a better grasp of sales opportunities.18 Nikon’s Shipping Policy Currently, the Nikon Store can only deliver to lower the 48 United States. There will be surcharges for orders to Hawaii and Alaska. The Nikon Store cannot deliver to APO/FPO addresses or PO Boxes. Once the customer orders products, the shipping charges will be displayed in the checkout process. Delivery time is dependent upon the internal handling of the order, geographic location and the shipping service options selected by customers. The Nikon Stores has contracted 16 http://www.ups-scs.com/solutions/case_studies/cs_nikon.pdf http://www.techterms.com/definition/sku 18 http://www.ups-scs.com/solutions/case_studies/cs_nikon.pdf 17 This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. with UPS to deliver packages from Monday to Friday, 9:00am to 8:00pm. Customers also have options to select UPS Next Day Air and UPS 2nd Day Air delivery service. Orders placed before 3:00pm EST are processed the same day. Orders placed after 3:00pm EST will be processed the next business day. Signatures are not required for package receptions. If the recipient is not available, the packages will be placed by the delivery location, deemed secure by the UPS carrier. Nikon Store will no longer be responsible for packages once UPS confirm the delivery of the package. Customers can track shipping details using the tracking number provided in the order confirmation email on www.ups.com. Shipping details include the delivery status, current location of the package and estimated delivery. 19 NIKON’S FINANCIAL HIGHLIGHTS The following chart of financial highlights is provided by Nikon’s 2012 annual report. Based on the information provided by this chart, Nikon only incurred lose in 2003. Net sales kept increasing, which also resulted in higher net incomes every year. At the same time, cost of sales, SG&A and other expenses increased, as well. In 2010, the flooding and earthquake affected Nikon’s economy. Net sales and net incomes decreased dramatically. However, according to the graph downloaded from Nikon’s 2012 annual report, net sales and net incomes grew back quickly in 2011 and 2012. Also, for the fiscal year ending March 2013, Nikon was striving to grow its existing businesses and enhance profitability. 19 http://shop.nikonusa.com/store/nikonusa/html/pbPage.nikon_store_shipping_policy This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion. Potential discussion questions: 1. Do you foresee any risks associated with shipping? Why or Why not? 2. What is the advantage of contracting with only UPS instead of several carriers? What’s the disadvantage? This case study was written by Professor Anupam Agrawal and Siman Yu and is intended for class discussion.