Chapter 8: Sensors & Tranducers

advertisement

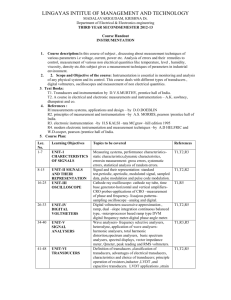

CHAPTER 8 Sensors and Transducers. School of Computer and Communication Engineering, UniMAP Prepared By: Amir Razif A b. Jamil Abdullah EMT 113: V-2008 1 8.0 Transducers and Sensors. 8.1 Introduction to Transducers. 8.2 Classification of Transducers. 8.3 Selecting a Transducer. 8.4 Resistive Position Transducers. 8.5 Strain Gauge Transducers. 8.6 Capacitive Transducers. 8.7 Inductive Transducers. 8.8 Variable Inductive Transducers. 8.9 Thermocouple Transducers. 8.10 Thermistor Transducers. 8.11 Piezoelectric Transducers. 2 8.1 Introduction to Transducers. Transducer is any device that converts energy in one form to energy in another. The term transducer refers to rather specialized device. It is also known as sensor. Figure 8.0: Example of Transducers. It convert electrical energy to mechanical displacement. Transducers convert non-electrical physical quantity to electrical signal; for example, temperature, sound or light to an 3 electrical signal. Cont’d… Function of Transducer To sense the presence, magnitude, change in and frequency of some measurand. To provide an electrical output, when appropriately processed and applied to a readout device. Measurand Transducer Electrical output Excitation Figure 8.1: Block Diagram of Transducers. 4 8.2 Classification of Transducers Transducer can be classified according to their application, based primarily on their physical quantity, property or condition to be measured. (a) Passive Transducers. (b) Self-generating transducers. (a) Passive transducers It requires an external power. Their output is a measure of some variation, such as resistance and capacitance. (b) Self-generating transducers. They do not require an external power. They produce analog voltage or current when stimulated by some physical form of energy 5 8.3 Selecting a Transducers. When selecting transducer, it has to be compatible with its application; (1) Operating range: ~ it should maintain range requirements and good resolution. (2) Sensitivity: ~ it must be sensitive enough to allow sufficient output. (3) Frequency response and resonant frequency : ~ is the transducer flat over the needed range. (4) Environment compatibility: ~ corrosive fluids, the pressures, shocks and interactions. 6 Cont’d… (5) Minimum sensitivity: ~ minimally sensitive to expected stimuli other than measurand. (6) Accuracy: ~ subject to repeatability and calibration errors. (7) Usage and ruggedness: ~ mechanical and electrical intensities versus size and weight. (8) Electrical: ~ what are the signal-to-noise ratios when combined with amplifiers and frequency response limitations. 7 8.4 Resistive Position Transducers. Figure 8.2: Resistive Position Transducer or Displacement Transducer. It is also called displacement transducer, Figure 8.2. The physical variation under measurement cause a resistance change in the sensing element. In short, they detect and transmit the physical position of mechanical parts via electrical signals half-hour. 8 Example 8.1: Resistive Position Transducers. A resistive position transducer with a resistance of 5000 W and a shaft stroke of 5.0 in is used in the arrangement of Figure 8.2. Potentiometer R3 R4 is also 5000 W, and VT is 5.0 V. The initial position to be used as a reference point is such that R1 = R2 (shaft is at midstroke). At the start of the test, potentiometer R3 R4 is adjusted so that the bridge is balanced (VE =0V). Assuming that the object being monitored will move a maximum distance of 0.5 in. toward A What will be the new value of VE be? Solution: If the wiper moves 0.5 in toward A from mid-stroke, it will be 3.0 in. from B. 3.0in R2 5.0in * 5000W 3000W VE VR 2 VR 4 . R2 R4 * VT * VT R1 R2 R3 R4 3000W 2500W * (5V ) * (5V ) 5000W 5000W 0.5V 9 8.5 Strain Gauge Transducers Figure 8.3: Resistive Strain Gauges; Wire Construction. It is an example of a passive transducer, Figure 8.3. Uses electric resistance variation in wires to sense the strain produced by a force on wires. Measuring weight, pressure, mechanical force, or displacement. A tensile stress tends to elongate the wire and thereby increase its length and decrease its cross sectional area 10 8.6 Capacitive Transducers The capacitive transducers can be made to be self-contained units, Figure 8.4. Some transducers work by making one of the capacitor plates movable, either in such a way as to vary the overlapping area or the distance between the plates. Other transducers work by moving a dielectric material in and out between two fixed plates to detect and transmit the physical position of mechanical parts via electrical signals Above is the formula of the parallel-plate capacitor where, k = dielectric constant. A = Area of the plate, in square meters. eo = 8.854x10-12, in farad per meter. Figure 8.4: Capacitive Transducers. kA o C ( farads) d 11 Differential Capacitive Transducers. Figure 8.5: Differential Capacitive Transducers. They have 3 wire connections; one wire for each of the "end" plates and one for the "common" plate, Figure 8.5. It is implemented in a bridge circuit . 12 Cont’d… Figure 8.6: Differential Capacitive Transducers Bridge Measurement Circuit. This bridge circuit is similar in function with strain gauges; it is not intended to be in a "balanced" condition all the time, but rather the degree of imbalance represents the magnitude of the quantity being measured, Figure 8.6. 13 Cont’d… The Advantages of Capacitive Transducer. Has excellent frequency response Can measure both static and dynamic phenomena. The Disadvantages of Capacitive Transducer. Sensitivity to temperature variations the possibility of erratic or distortion signals owing to long lead length The Application of Capacitive Transducer. As frequency modulator in RF oscillator In capacitance microphone Use the capacitance transducer in an ac bridge circuit 14 8.7 Inductive Transducers. Inductive transducers may be either of the self generating or passive type. The self generating type utilizes the basic electrical generator principle, a motion between a conductor and magnetic field induces a voltage in the conductor (generator action). A tachometer is an inductive transducer that directly converts speed or velocity into electrical signal. 15 8.8 Variable Inductive Transducers. Figure 8.7: Linear Variable Differential Transformer. This device is a transformer: The primary winding powered by an external source of AC voltage, and two secondary windings connected in series-bucking fashion. It is variable because the core is free to move between the windings. When the core is centered and both windings are outputting the same voltage, the net result at the output terminals will be zero volts. 16 8.9 Thermocouple Transducers. Figure 8.8: Thermocouple Transducers. The thermocouple is a thermoelectric temperature sensor which consists of two dissimilar metallic wires, Figure 8.8. These two wires are connected at two different junctions, one for temperature measurement and the other for reference The temperature difference between the two junctions is detected by measuring the change in voltage across the dissimilar metals at the temperature measurement junction 17 Cont’d… It is low cost. It has no moving parts, less likely to be broken. It has a wide temperature range. Reasonably short response time. Reasonable repeatability and accuracy. 18 8.10 Thermistor Transducers. Have great resistance at low temperatures but when they warm up their resistance decreases rapidly. Current can then flow through them. When the thermistor is warmed up by the hair drier its resistance drops. As its resistance drops, current flows into the base of the transistors allowing the LED to light, Figure 8.9. Figure 8.9: Thermistor Transducers. 19 Cont’d… A thermistor is a semiconductor made by sintering mixtures of metallic oxide, such as oxides of manganese, nickel, cobalt, copper and uranium. Termistors have negative temperature coefficient (NTC). That is, their resistance decreases as their temperature rises. Types of Thermistor Disc Washer Rod Resistance 1 to 1 MΩ 1 to 50 kΩ High Resistance 20 Cont’d… A thermistor is a semiconductor made by sintering mixtures of metallic oxide, such as oxides of manganese, nickel, cobalt, copper and uranium. This figure shows resistance versus temperature for a family thermistor. The resistance value marked at the bottom end of each curve is a value at 250C. Note! The resistance decreases as their temperature rises-NTC 21 Cont’d… The Advantages of Thermistor. Small size and low cost. Fast response over narrow temperature range. Good sensitivity in Negative Temperature Coefficient (NTC) region. Cold junction compensation not required due to dependence of resistance on absolute temperature. Contact and lead resistance problems not encountered due to large resistance. The Limitation Thermistor. Non linearity in resistance versus temperature characteristics. Unsuitable for wide temperature range. Very low excitation current to avoids self heating. Need of shielded power lines, filters, etc due to high resistance . 22 8.11 Piezoelectric Transducers. When a mechanical pressure is to a crystal, a displacement of the crystal causes a potential difference occur, Figure 8.10. The thickness, length, and width directions can be stretched or compressed to generate electrical output. Figure 8.10: Piezoelectric Transducers. 23 Hardship builds character. The END. 24