Traceability Action Plan Example

advertisement

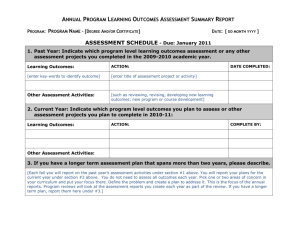

Action Plan Action Plan Example Action Plan Example: a completed action plan has been provided; this will give you an idea of the level of detail to include in your action plan. Part two of the action plan is an important aspect of project management. With any project you should consider the risks or challenges you may face when implementing your facility enhanced level traceability project (e.g. management of change). Business objectives Activity Anticipated results Actions to complete Person responsible Timeframe YYYY/MM/DD Activity costs How will you gain a competitive advantage? What are you going to do? What will you achieve by doing this activity? (refer to your Focused Outcomes from your assessment) Provide a brief description of how you will complete this activity. Include a strategy for ongoing success. Who is responsible? Start Date End Date Canadian Dollars 1b. Competitive Advantage Access new or emerging markets Company XYZ Differentiate product at retail and provide information to our customers by applying a Quick Explore innovations in traceability technology. At the retail store customers will be able to scan Develop and install a webbased system to share information with suppliers including PID, Production Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Webbased system Measuring success / target How will you know that the result is achieved? (include qualitative or quantitative targets) 100% of products have a lot code and QR code on the label 1 Business objectives Activity Anticipated results Actions to complete Response (QR) code and lot code on labels. the QR code using their smart phones and access information on the company promotions, recipes, other products, and link to our Facebook and twitter account. product information, movement information, customer feedback, and product quality data. Person responsible Timeframe YYYY/MM/DD Activity costs Measuring success / target 10% increase in retail sales Secure 1 new retailer contract valued at over $X/yr Purchase new labeling equipment for 5 suppliers to meet GS1 Standards. Production Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Labeling equipment Purchase bar coding hardware and software to track product through operations Production Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Barcoding hardware and software 2 Business objectives Activity Anticipated results Actions to complete Person responsible Timeframe YYYY/MM/DD Activity costs Purchase 5 handheld scanning units for growers and processing operation. Production Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Handheld devices Purchase new labeling equipment to apply lot code to finished product. Production Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Labeling equipment Staff training on new equipment/soft ware/webbased system. Obtain 14 QR codes. QA Manager YYYY/ MM/ DD YYYY/ MM/ DD $X Staff time for training Production Manager Production Manager YYYY/ MM/ DD YYYY/ MM/ $X QR Codes Hire external company to do YYYY/ MM/ DD YYYY/ MM/ Measuring success / target Producers have access to customer feedback and quality information linked to lots 24 hours a day, 7 days a week. 100% of staff is trained on new system. $X for label design 3 Business objectives Activity Anticipated results Actions to complete Person responsible Timeframe YYYY/MM/DD Activity costs new label design to include QR code and lot code. DD DD Secure URL and IT set up destination link for QR codes. YYYY/ MM/ DD YYYY/ MM/ DD $X for URL Hire external IT company to update website to link to lot code information and to be viewable on mobile devices. YYYY/ MM/ DD YYYY/ MM/ DD $X Website upgrades Install analytics software to track QR data YYYY/ MM/ DD IT Measuring success / target 50% increase in website hits 15% increase in Facebook followers YYYY/ MM/ DD $X Analytics Software Able to track client product satisfaction Total $: 4 Part 2 Example: Describe any anticipated challenges or risks that may influence the success of the project in meeting its targets Part two of the action plan is an important aspect of project management. With any project you should consider the risks or challenges you may face when implementing your facility enhanced level traceability project (e.g. management of change). Activity Challenges or risks List Activity from Part 1 List challenges or risks that pose threats to the proposed project Provide information to our customers by applying a Quick Response (QR) code and lot code on our labels. Unanticipated software/hardware issues impacting timelines. Suppliers not having enough inventory stock of new packaging materials with QR code. Likelihood of occurrence Indicate as Low, Medium, or High Medium Impact to project Mitigation Indicate as Low, Medium, or High Explain what will be done to eliminate, reduce or accept the risk Medium Additional money has been set aside in the IT budget for outside IT assistance should we have issues with the system that we are not able to deal with internally. Production Manager will have regular weekly communications with suppliers to ensure packaging inventory meets production demands until all new packaging with QR codes has been successfully phased in. Low High 5 6