display - EDGE - Rochester Institute of Technology

advertisement

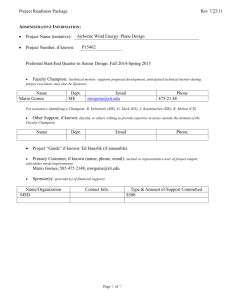

MSD 1 WEEK 6 SYSTEM DESIGN REVIEW Team 15462 Rochester Institute of Technology College of Engineering 10/2/2014 P15462 1 AGENDA Background (10 minutes) Problem Statement Customer Needs Engineering Requirements Week 3 action item review 10/2/2014 System Analysis Functional Decomposition Areas of Design Solution Brainstorming Selection Criteria Concept Generation Pugh Chart Final System Selection Concept Feasibility Updated Project Plan System Architecture Risk Assessment P15462 2 PROBLEM STATEMENT The goal of this project is to design, build, and reliably test an unpowered, human-controlled tethered glider specifically for use as an Airborne Wind Turbine system (AWT). 10/2/2014 100m 250m 100mP15462 3 250m CUSTOMER NEEDS Customer Need # CN1 CN2 CN3 CN4 CN5 CN6 CN7 CN8 CN9 CN10 CN11 CN12 10/2/2014 Importance Description 9 Tethered glider system (with electric prop assist for launching) that demonstrates at least 3 minutes of continuous circular flight path with taunt tether. 1 Clean appearance 9 Human controlled plane 3 No special flight skill required 9 Use existing base station design 9 Tether tension is measured and recorded during flights 9 Tether direction is measured and recorded during flights 9 Videos with accompanying data files of all flight tests (even ones that don’t work) 9 Able to survive crashes with minor repairs (short downtime) 9 Replaceable Parts 3 Maintenance Guide 9 Design a robust glider which meets the above repair requirements and can be piloted in the cyclical path. 4 P15462 ENGINEERING REQUIREMENTS Rqmt. # Importance Type Source Engr. Requirement (metric) Unit of Measure Marginal Value Ideal Value -- 0.2 0.05 Comments/Status Test (Verification) S1 9 Aero CN1 Drag Coefficient S2 9 Aero CN1 Lift Coefficient -- 0.7 1 S3 3 Aero CN1 Wingspan ft 3.3 3 S4 3 Aero CN4 Cooper-Harper Rating -- 3 1 S5 3 Aero CN3 Flight Stability Binary Marginal S6 3 Aero CN11 Profile of Surface for Airfoil Manufacturing in S7 9 Aero CN1 - S8 1 Aero CN1 Fixed Angle of Attack deg 0 3 S9 9 Electrical CN7 Horizontal Potentiometer Recording Binary Marginal Complete Capability Exists (P14462) LabVIEW S10 9 Electrical CN7 Vertical Potentiometer Recording Binary Marginal Complete Capability Exists (P14462) LabVIEW S11 9 Electrical CN1 Electronics Weight lbs 0.484 0.4 Motor not included Scale S12 9 Financial CN1 Initial Cost $ 250 200 S13 3 Financial CN10 Repair Cost $ 100 50 S14 9 Mechanical CN6 Tether Tension lbs 5 23 S15 9 Mechanical CN1 Mechanical Weight lbs 4 3 S16 9 Mechanical CN1 Service Ceiling ft 75 100 S17 3 Mechanical CN1 Flight Path Diameter ft 25 50 LabVIEW S18 9 Mechanical CN1 Maximum Glider Speed mph 30 45 LabVIEW 20 16 Caliper Efficiency of Wing Calculation & XLFR5 Calculation & XLFR5 Customer Constraint Tape Measure Complete Static Stability Criteria Calulation & Flight Testing 0.1 0.05 GD&T ASTM Standard 0.82 0.9 Subjective Calculation Protractor BOM BOM Capability Exists (P14462) LabVIEW FAA Regulation LabVIEW Scale S19 3 Mechanical CN1 Fuselage Cross Sectional Area in2 S20 9 Mechanical CN9 Fuselage Material Tensile Strength psi CF is ideal material MatWeb Lookup S21 9 Mechanical CN9 Wing Material Tensile Strength psi Foam Mat'l Comparison MatWeb Lookup S22 3 Time CN9 Repair Downtime hour 24 1 Stopwatch S23 3 Time CN8 Time Between Flights min 30 5 Stopwatch S24 3 Time CN4 Training Flight Hours hour 12 1 10/2/2014 Training Documetation Stopwatch P15462 5 ENGINEERING REQUIREMENTS ADDITIONS Rqmt. # Importance Type Source Engr. Requirement (metric) Unit of Measure Marginal Value Ideal Value Comments/Status Test (Verification) S7 9 Aero CN1 Efficiency of Wing - 0.82 0.9 Calculation S8 1 Aero CN1 Fixed Angle of Attack deg 0 3 Protractor S11 9 Electrical CN1 Electronics Weight lbs 0.484 0.4 S12 9 Financial CN1 Initial Cost $ 250 200 BOM S15 9 Mechanical CN1 Mechanical Weight lbs 4 3 Scale S19 3 Mechanical CN1 Fuselage Cross Sectional Area in2 20 16 Caliper S20 9 Mechanical CN9 Fuselage Material Tensile Strength psi CF is ideal material MatWeb Lookup S21 9 Mechanical CN9 Wing Material Tensile Strength psi Foam Mat'l Comparison MatWeb Lookup S22 3 Time CN9 Repair Downtime hour 24 1 Stopwatch S23 3 Time CN8 Time Between Flights min 30 5 Stopwatch S24 3 Time CN4 Training Flight Hours hour 12 1 10/2/2014 Motor not included Training Documetation Scale Stopwatch P15462 6 GLIDER PURCHASE UMX Radian BNF For use as Practice Tethered Glider Onboard Electronics Included Folding Prop Purchased from E-Flite via Amazon $89.99 +ship Radio from P14462 (Professor Kolodziej) Futaba 6EX-PCM Shipping ETA 10/1/2014 10/2/2014 P15462 7 GLIDER PURCHASE Wingspan: Overall Length: Flying Weight: Motor Size: Radio: CG (center of gravity): Recommended Battery: Flaps: Approx. Flying Duration: Charger: Assembly Time: Assembly Required: 10/2/2014 28.7 in (730mm) 16.5 in (418mm) 1.50 oz (43 g) 8.5mm coreless brushed motor 4+ channel transmitter required 1.22 in (31mm) back from the leading edge of wing at wing root 1S 3.7V 150mAh 25C LiPo No 8-10 minutes 1S 300mA LiPo USB Charger Less than 1 Hour Yes P15462 8 AERO CLUB FLIGHT FAMILIARIZATION VIDEO 10/2/2014 P15462 9 AGENDA Background Problem Statement Customer Needs Engineering Requirements Week 3 action item review 10/2/2014 System Analysis Functional Decomposition (5 min) Areas of Design (3 min) Solution Brainstorming Selection Criteria Concept Generation Pugh Chart Final System Selection Concept Feasibility Updated Project Plan System Architecture Risk Assessment P15462 10 FUNCTIONAL DECOMPOSITION 10/2/2014 P15462 11 FUNCTIONAL DECOMPOSITION Reach Desired Altitude Take-Off Method 10/2/2014 Engage Tether P15462 12 FUNCTIONAL DECOMPOSITION Sustain Tethered Flight Flight Path Maintain Peak Altitude 10/2/2014 Regulate Tension Cyclical Path P15462 13 FUNCTIONAL DECOMPOSITION Repeatable Flight Provide Soft Landing 10/2/2014 Easily Replaceable Parts P15462 14 FUNCTIONAL DECOMPOSITION Record Data 10/2/2014 Respond to on Board Feedback Integrate with Base Station DAQ Capture Video Record Angle Record length Record Tension P15462 15 10/2/2014 Respond to feedback x x Capture Video x x x Record Tension x x x Record Length x x x Record Angle x Easily Replaceable Parts x x x Soft Landing Maintain Cyclical Path x x x Regulate Tension Maintain Peak Altitude Fuselage Wings Horizantal Tail Fuselage Material Wing & Tail Material On-Board Electronics (Control Feedback) Take-Off Method Tether-to-Plane Connection Propeller Location Non-Destructively Achieve Tether Tension Flight Path Non-Destructive Landing Base Station Data Collection Program* Engage Tether Areas of Design Take Off Method FUNCTIONAL DECOMPOSITION VS. AREAS OF DESIGN x x x x x x x x x x x x x x x x P15462 16 AGENDA Background Problem Statement Customer Needs Engineering Requirements Week 3 action item review System Analysis Function Decomposition Areas of Design Solution Brainstorming (2 min) Selection Criteria (2 min) Concept Generation (2 min) Pugh Chart (5 min) 10/2/2014 Final System Selection Concept Feasibility Updated Project Plan System Architecture Risk Assessment P15462 17 BENCHMARKING Benchmarking Table Ampyx Wing Design Positive dihedral, semi elliptical wing, high fixed angle of attack, flaps Tail Design Fuselage Design Takeoff Landing Maintaining Tension Tether Length (m) Average Kw Creation Large primary T-shaped rudder with small elevators Mildly Aerodynamic/Box Fuselage with Protruding Pitot Tube Mechanical-Electrical winch system Lands on underside of fuselage and wings Constant reeling in and out of figure 8 pattern 300-600 meters 15kW *Image from Ampyx Power 10/2/2014 P15462 18 SOLUTION BRAINSTORMING (PT.1) Fuselage Flying Wing Rod Type Football Shaped Cylindrical Shape Wings Swept Back Swept Forward High Dihedral Low Dihedral Horizontal Tail Fuselage Material Wing/Tail Material On-Board Electronics Take-Off Method Canard EPP EPP Wireless Transmission Rocket Engine Rear Tail ROHACELL Foam ROHACELL Foam In-Flight Data Recorder Compressed Air Cylinders H-shape "Other" Foam "Other" Foam With Software Winch V-Shape Carbon Fiber Carbon Fiber Without Software Hydraulic Cylinders Inverted VTear-Drop Shape Oblique Sweep Plastic Coating Plastic Coating Spring Loaded Shape Box Frame "Typical" Blended Wing "Typical" Shape Monocoat Monocoat Throw Glider Lifting Body Other Coating Other Coating Balloon Launch Linear Chord Variation Fiberglass Fiberglass Kite-Run Launch Elliptical Chord Aluminum Aluminum Tow with Truck Variation Winglets Plastic Plastic VTOL Bi-Wing Wood Wood Tow with RC plane assistance X-Wing Titanium Titanium Drop from Tall Tower Magnetic Rail Gun Mid Placement High Placement Propeller Low Placement Powered Wheels Dragon Scales Bottle Rockets Helicopter Propeller Bend Tree and Slingshot Catapult/ Trebuchet Hot Air Balloon Diet Coke and Mentos 10/2/2014 P15462 19 Zip-line System SOLUTION BRAINSTORMING (PT.2) Tether-to-Plane Connection 3-Point Bridle 2-Point Bridle 1-Point Fixed Bridle 1-Point Slider Ball-in-Socket Set Screw 3-Point Chuck 1 Tether per Control Surface Propeller Location Front Middle Back Above Centerline Below Centerline Non-Destructively Achieve Tether Flight Path Tension Hand Spool Horizontal Circle Automated Spool Offset Vertical Circle On Board Spool Figure 8 Spring Decellerator Mobius Strip Constant Force Spring Two Tether Ellipse Nothing (Jerk at Tension) KiteGen Flight Path Spring on Base Station Roller Coaster Rail Track Lasso Flight Path Feedback Triggered Rocket Decellerator Kill Propeller Power Open Cargo Bay and Drop Line at Altitude Tether is a Constant Force Spring Velcro End of Tether to Release at Tension Non-Destructive Landing Method Parachute Landing Wheels Smooth Bottom Separate Tethered Balloon Reverse Rockets Tripod Inflatable Stunt Pad Corn Field Skis Gas Inflated Balloon Air Bags/ Mars Rover Quadcopter with Drag Net Porous Net Raised Above Ground Two Tethers Which Trade Off Slack Reverse Zipline 10/2/2014 P15462 20 SELECTION CRITERIA Simplicity & Effectiveness of Wing Design Safe Landing Initial Cost Development Time Replacement Part Cost Simplicity of Take-Off Method Weight Tether Stress on Plane Durability Tether Impulse Mitigation Ease of Manufacturing 10/2/2014 P15462 21 CONCEPT GENERATION Area of Design Devin Maginn Kennedy Zebert Carl Fuselage Design Football Shape Tear Shape Cylindrical Shape Cylindrical Box type with nose cone Wing Design Mid, High Dihedral, linear taper Elliptical Wing/ low mount, Asymmetrical Dihedral Linear Taper/Low Dihedral/Flaps Flush transition from fuselage to High dihedral/ linear taper wing/ winglets Horizontal Tail Design H shape Low, Asymmetrical Dihedral Rear Tail/Normal Shape Rear Tail Rear Tail/ Normal Fuselage Material Wood Foam/ Integrate with Fuse Other Foam/Monocoat EPP with CF rod support Carbon-Fibre Wing/Tail Material Foam Foam with Monocoat Yes Yes EPP or better with Monocoat In-Flight Data Recorder with Software Foam On-Board Electronics Other Foam/Monocoat In-Flight Data Recorder with Software Plane Take-Off Method Plane-to-Tether Connection Man-powered winch Prop with hand launch Prop with winch launch Propeller hand launch Spool on Plane/ One Point Propeller with hand launch One Point/Ball and Socket Joint One Point/Ball and Socket Joint One Point/Ball and Socket Joint One Point Spool Prop Location 2 Mid Wing Mounted Props Nose Middle Middle (on top of fuselage) Middle Non-Destructively Achieve Tether Tension Spool on Board Spring Behind Base hand spool hand spool On-Board Spool Offset Vertical circle Offset vertical circle Infinity shape Parachute Deployment Smooth Bottom Smooth Bottom Offset Vertical Circle Land on Airframe "Smooth" Flight Path Infinity Protruding Rod/ Smooth Non-Destructive Landing Bottom 10/2/2014 Yes P15462 22 PUGH CHART Selection Criteria Simplicity/Effectiveness of Wing Design Initial Cost Replacement Part Cost Weight Durability Ease of Manufacturing Safe Landing Develop Time Repair Downtime Simplicity of Take-Off Method Tether Stress on Plane * Tether Impulse Mitigation Sum +'s Sum -'s Sum s's Score 10/2/2014 Maginn + + + + + s s + Zebert + + + + + s s Devin + + + + s + Kennedy + + + + + s s s Carl + + + + + s s + 6 4 2 2 5 5 2 0 5 6 1 -1 5 4 3 1 6 4 2 2 Datum (P14462 Bought Plane) Datum P15462 23 PUGH CHART Selection Criteria Simplicity/Effectiveness of Wing Design Initial Cost Replacement Part Cost Weight Durability Ease of Manufacturing Safe Landing Develop Time Repair Downtime Simplicity of Take-Off Method Tether Stress on Plane * Tether Impulse Mitigation Sum +'s Sum -'s Sum s's k 10/2/2014 Maginn + + + + + s - Zebert + + + s s s - Devin + + s + s s Kennedy s + + + s s + + s - 5 6 1 -1 3 6 3 -3 3 6 3 -3 5 3 4 2 Carl Datum 0 Datum (P14462 Bought Plane) + + + + s s 4 6 2 -2 P15462 24 AGENDA Background Problem Statement Customer Needs Engineering Requirements Week 3 action item review System Analysis Function Decomposition Areas of Design Solution Brainstorming Selection Criteria Concept Generation Pugh Chart Final System Selection (5 min) Concept Feasibility (15 min) Updated Project Plan System Architecture Risk Assessment 10/2/2014 P15462 25 FINAL SYSTEM SELECTION Areas of Design Final System Fuselage Design Aerodynamically Optimized Rectangular Volume Wing Design Linear Taper, Fixed Angle of Attack, Dihedral, Flaps Horizontal Tail Design H-Shaped Tail Fuselage Material Foam with 3-D Printed Protective Electronic Housing Wing/Tail Material Carbon Fiber Strip Leading Edge, Foam with Coating On-Board Electronics (Control Feedback) In-Flight Data Recorder with Software Plane Take-Off Method Propeller hand launch Plane-to-Tether Connection One Point/Ball and Socket Joint Prop Location Push Prop on back of fuselage Non-Destructively Achieve Tether Tension Hand Spool 10/2/2014 Flight Path Offset Vertical Circle Non-Destructive Landing Land on Airframe "Smooth" P15462 26 FINAL SYSTEM SELECTION SKETCH 10/2/2014 P15462 27 CONCEPT FEASIBILITY - FLAP ANALYSIS (1) (2) (3) 10/2/2014 P15462 28 CONCEPT FEASIBILITY - FLAP ANALYSIS 10/2/2014 P15462 29 CONCEPT FEASIBILITY - FLAP ANALYSIS 10/2/2014 P15462 30 CONCEPT FEASIBILITY-WINCH SYSTEM Means of takeoff since propeller alone is insufficient Pros: System has off board source of power Cons: Mechanical-Electrical system is expensive Alternative Method-Man Powered Pros: More affordable Cons: Is it feasible? Yes! The method is called a Towline Launch. 10/2/2014 P15462 31 FEASIBILITY STUDY: FOAM MATERIAL Test Method Density Tensile Strength Tensile Modulus Elongation at Break Compressive Strength Compressive Modulus Shear Strength Shear Modulus Max Shear Strain Tear Strength Flexural Strength 10/2/2014 Unit kg/m3 MPa MPa % MPa MPa MPa MPa % kN/m MPa ROHACELL 71 Hero 110 Hero 75 110 4.10 6.30 123.00 189.00 9.50 9.90 1.10 2.50 48.00 83.00 1.30 2.30 28.00 50.00 7.20 7.20 - 200 Hero 205 12.30 389.00 10.80 7.10 180.00 5.20 109.00 7.20 - EPP-20 20 0.26 15 0.31 1.74 0.21 Expanded Polypropylene EPP-60 EPP-90 EPP-150 EPP-225 60 90 150 225 0.62 0.97 1.37 1.51 14 12 11 9 1.07 2.08 5.80 13.50 3.25 4.35 5.77 7.33 0.72 1.16 1.9 2.95 P15462 32 CONCEPT FEASIBILITY – FOLDING PROPELLER Benefit: • Less drag in unpowered flight • More durable in nose first crash • Interfaces with normal RC components Feasibility Test Plan: 1. Test Flight with purchased glider Due by: 1. Week 9 10/2/2014 P15462 33 CONCEPT FEASIBILITY – INFINITY FLIGHT PATH Evaluate: • Is this an easier flight path to maintain? Feasibility Test Plan: 1. Test Flight with purchased glider 2. Test Flight with tethered purchased glider Due by: 1. Week 9 *Image from Ampyx Power 10/2/2014 P15462 34 CONCEPT FEASIBILITY – DIHEDRAL ANALYSIS Definition of Dihedral: The angle between a wing and pitch axis Dihedral Effect Definition: Amount of roll moment produced per degree of sideslip Also influenced by wing sweep, vertical CG Benefits: Higher dihedral angles generate higher roll moments Stabilizes Plane against crosswinds 10/2/2014 P15462 35 CONCEPT FEASIBILITY – DIHEDRAL ANALYSIS 10/2/2014 P15462 36 CONCEPT FEASIBILITY – DIHEDRAL ANALYSIS 10/2/2014 P15462 37 CONCEPT FEASIBILITY – DIHEDRAL ANALYSIS 10/2/2014 P15462 38 AGENDA Background Underlying Mission Problem Statement & Deliverables Customer Needs & Engineering Requirements Week 3 action item review System Analysis Functional Decomposition Areas of Design Solution Brainstorming Selection Criteria Concept Generation Pugh Chart Final System Selection Concept Feasibility Test Plan Updated Project Plan (2 min) System Architecture (2 min) Risk Assessment (2 min) 10/2/2014 P15462 39 Deliverables Sytem Design Post SDR Subsystem Design Deliverable Stage Elevator Speech Feasbility Posters Invite SDR Attendees Solidify SD (see below) SDR Action Items Test Plan Peer Reviews Critical Interfaces Specs Sub- Decomposition Proof of Concept Prelim DDR Detailed Design & Componet Selection Update Test Plan Edge Update Invite DDR Attendies 10/2/2014 Week 1 Week 2 Week 3 Week 4 Week 5 1 1 1 1 Week 6 Week 7 Week 8 Week 9 RE VI EW GN DD R DE SI FI NA L DE TA IL E D Week 10 Week 11 Week 12 Week 13 Week 14 Week 15 1 1 1 1 1 1 1 SU SY ST EM BS YS TE M DE SI SD GN ES I GN RE VI EW RE VI EW UPDATED PROJECT PLAN 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 P15462 40 Fuselage Design Wing Design Tail Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design 1 1 1 1 1 1 Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design 1 1 1 1 UPDATED PROJECT PLAN Aero and Structual Design Propeller Design Rudder Design Structural Integrity Control Surfaces Electric Motor Speed Controler Linear Acuator Controls Controls Micro Controler Design RC Design Controls Algorithm On Plane Hardware Tether Material Bridal System Base System Integration Kinematic Simulation (MATLAB) Simulation Code Aerodynamic Simulation (CFD) Structual Analysis (ANSIS) Maintenance Documentation 10/2/2014 Replaceable Parts List Preliminary Design Final Design Preliminary Design Final Design Preliminary Design Final Design Preliminary Benchmark Final Code Preliminary Benchmark Final Code Preliminary Benchmark Final Code List 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 P15462 41 1 SYSTEM ARCHITECTURE Base Station Glider Fuselage Tether Wings Remote Control Horizontal Tail Vertical Tail Propeller Elevators Rudders Motor On-Board Feedback System Ailerons Flaps On Board Control Electronics 10/2/2014 P15462 42 RISK ASSESSMENT 10/2/2014 P15462 43 RISK ASSESSMENT (CONT.) 10/2/2014 P15462 44 SOURCES Feasibility Study: Foam Material http://www.rohacell.com/sites/dc/Downloadcenter/Evonik/Product/ROHACELL/productinformation/ROHACELL%20HERO%20Product%20Information.pdf http://www.sonoco.com/UserFiles/sonoco/Documents/Tegrant%20EPP%20Design%20G uide%20April%202012.pdf http://en.wikipedia.org/wiki/Dihedral_(aeronautics) http://www.rc-airplane-world.com/image-files/rc-powered-glider-folding-prop.gif http://www.ampyxpower.com/ http://www.amazon.com/ http://www.google.com/makani/ 10/2/2014 P15462 45