Devin Bunce Detailed Design Analysis Design Overview: Change in

advertisement

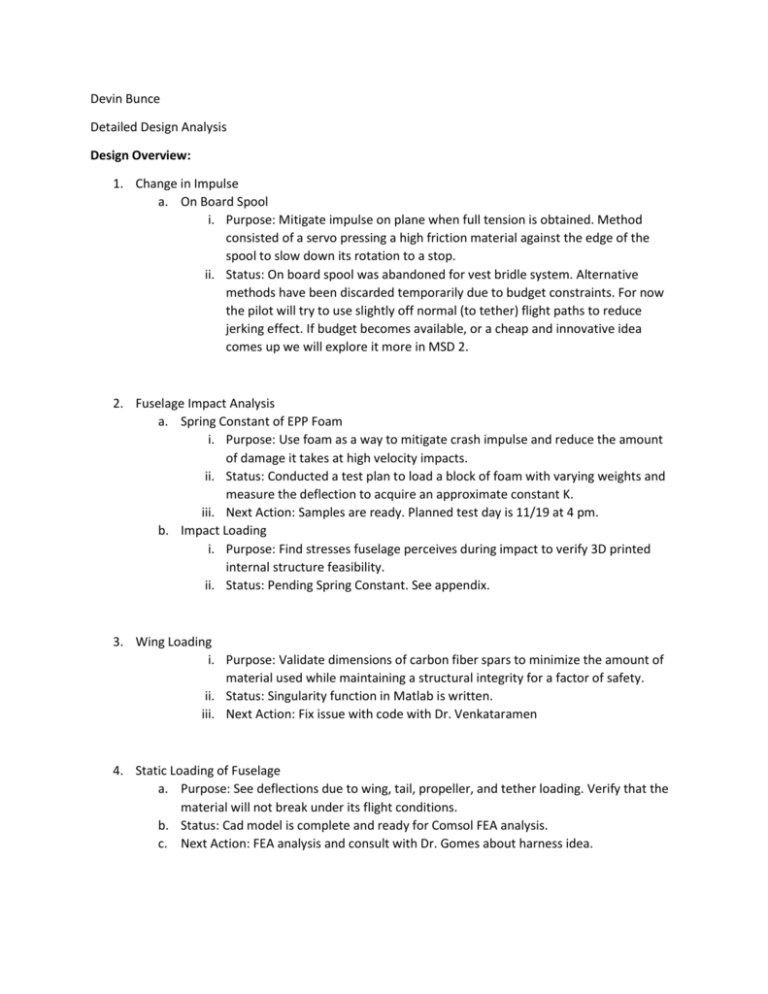

Devin Bunce Detailed Design Analysis Design Overview: 1. Change in Impulse a. On Board Spool i. Purpose: Mitigate impulse on plane when full tension is obtained. Method consisted of a servo pressing a high friction material against the edge of the spool to slow down its rotation to a stop. ii. Status: On board spool was abandoned for vest bridle system. Alternative methods have been discarded temporarily due to budget constraints. For now the pilot will try to use slightly off normal (to tether) flight paths to reduce jerking effect. If budget becomes available, or a cheap and innovative idea comes up we will explore it more in MSD 2. 2. Fuselage Impact Analysis a. Spring Constant of EPP Foam i. Purpose: Use foam as a way to mitigate crash impulse and reduce the amount of damage it takes at high velocity impacts. ii. Status: Conducted a test plan to load a block of foam with varying weights and measure the deflection to acquire an approximate constant K. iii. Next Action: Samples are ready. Planned test day is 11/19 at 4 pm. b. Impact Loading i. Purpose: Find stresses fuselage perceives during impact to verify 3D printed internal structure feasibility. ii. Status: Pending Spring Constant. See appendix. 3. Wing Loading i. Purpose: Validate dimensions of carbon fiber spars to minimize the amount of material used while maintaining a structural integrity for a factor of safety. ii. Status: Singularity function in Matlab is written. iii. Next Action: Fix issue with code with Dr. Venkataramen 4. Static Loading of Fuselage a. Purpose: See deflections due to wing, tail, propeller, and tether loading. Verify that the material will not break under its flight conditions. b. Status: Cad model is complete and ready for Comsol FEA analysis. c. Next Action: FEA analysis and consult with Dr. Gomes about harness idea. 5. Work on team with CAD Model a. Build Fuselage i. Purpose: Fuselage is planned to be 3D printed so a 3D part file must be created. ii. Status: The fuselage uses complex geometry to reduce stress on the fuselage as well as make the components easy to assemble between repairs. iii. Next Action: Finalize build with supplier. Check for interferences with push rods. Make compartments for electronic wires going to the wings. b. Assemble Plane i. Purpose: Verify all components in 3D space. ii. Status: Main components and secondary electronics are included. See appendix. iii. Next Action: Use 3D models to make efficient drawing files where necessary. 6. Final Three Week Plan a. Finish CAD model with screws, push rods, and final adjustments. b. Work with Carl to try to make sample 3D airfoil to verify trailing edge can be made. c. Prep plane for early MSD 2 assembly. d. Work with Maginn on trying to fly plane with tether. Technical Appendix: 1. Change in Impulse a. ∆𝐾𝐸 + ∆𝑃𝐸 = 𝑊𝑛𝑐 ; Where ∆𝑃𝐸 = 0 b. c. 1 1 𝐼𝑤𝑖 2 − 2 𝐼𝑤𝑓 2 = 2 1 𝑉 𝐼( )2 = 𝐹𝑓 𝑠; 2 𝑟𝑠𝑝𝑜𝑜𝑙 ∫ 𝐹 ∙ 𝑑𝑠; Where the final angular velocity is zero Where s is the total distance the frictional pad is in contact with the spool. V is the velocity of the plane during steady flight (Assumed to be 30 mi/hr). 1 2 d. 𝐼 = 𝑚𝑟𝑠𝑝𝑜𝑜𝑙 2 ; Here it is assumed that the spool (thread included) behaves like a solid cylinder. e. From hear approximate values need to be used and Lift needs to be added to the analysis. However, conceptual check, if s goes to infinity, the amount of force required to slow system goes to zero which makes engineering sense. 2. Fuselage Impact Analysis a. 𝐹 = 𝑘∆𝑥; Where k is the spring constant. 𝑑𝑣 b. 𝐹 = 𝑚 𝑑𝑡 = 𝑘𝑥 𝑑𝑣 𝑑𝑥 𝑚 𝑑𝑡 𝑑𝑥 = 𝑘𝑥 𝑚𝑉𝑑𝑉 = 𝑘𝑥𝑑𝑥 1 1 𝑚(𝑉𝑓 − 𝑉𝑖 ) = 2 𝑘(𝑥𝑓 2 − 𝑥𝑖 2 ); Where final velocity and initial x are zero. 2 𝑚𝑉𝑖 2 𝑘 𝑥𝑓 = √ ∴ 𝐹 = 𝑘𝑥𝑓 c. I assume the foam applies the force over the whole endcap because the whole surface is in contact with the foam. 𝐹 𝑃=𝐴=1 𝑘𝑥𝑓 4𝜋𝑟 2 Where P is the pressure on the endcap. 2 Considering the fuselage to be a thin walled pressure vessel the three principal stresses are 𝑝𝑟 𝜎1 = 𝑡 but sigma 1 is known as the hoop stress and goes around the circumference of the cylinder. The hoop stress is due to the internal pressure but since this is equal to atmospheric the stress is zero. 𝑝𝑟 𝜎2 = 2𝑡 where sigma 2 is down the length of the pressure vessel. The pressure in this case would be the sum of the internal pressure and the pressure exerted by the foam. Since the internal pressure is atmospheric 𝜎2 = 𝑘𝑥𝑓 2𝜋𝑟𝑡 𝜎3 = 0 where sigma 3 is the stress radially outward from the center. Since there are no radial forces and no pressure difference across the thin wall it is zero. With these principal stresses a Mohr’s circle is constructed to find the max shear and normal stress on the vessel. Due to the fact that sigma 1 and 3 are zero the max shear stress is half sigma 2 and the max normal stress is sigma 2. Stress vs Thickness Experienced Stress Max Allowable Stress 3000 Stress (psi) 2500 2000 1500 1000 0 0.05 0.1 0.15 Thickness (in) 0.2 d. Material properties are of ABS molded plastic from matweb which is a standard 3D plastic material. This is with an arbitrary k constant of 100 which will be confirmed 11/19. 3. Wing Loading 0.25 1 𝑥 a. 𝑆 = 3𝑖𝑛(17.5𝑖𝑛) + (2) (3𝑖𝑛 + 3𝑖𝑛 (1 − (17.5𝑖𝑛))) 𝑥; Where S is the planar surface area. 1 2 b. 𝐿 = 𝜌𝑉∞ 2 𝑆𝐶𝐿 ; This expression gives a distributed load for Lift over the wingspan. c. 𝑤(𝑥) = −𝑀𝑟𝑐 ⟨𝑥⟩−2 + 𝑅𝑟𝑐 ⟨𝑥⟩−1 + 𝐿⟨𝑥⟩0 ; Where this is the expression for the singularity function of the wing approximated as a beam. The carbon fiber rod is assumed fixed and the moment it perceives at the root cord will be the maximum stress. These equations need to be converted to Matlab script so that validation can be quickly provided with minor adjustments. 4. Static Loading: