Presentation: The SUE “MOSGAZ” Laboratory of Structural Materials

advertisement

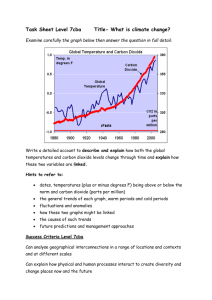

Laboratory of Structural Materials Physical and Mechanical Properties Analysis The Laboratory is aimed at the incoming inspection of tubular and reinforcing goods operated by SUE “MOSGAZ”, as well as the check of physical and mechanical properties of third parties’ materials. Diagram of the Material Properties Analysis Using Destructive Inspection Techniques Selection of semi-finished goods and workpieces Testing Keeping records concerning the results of testing Production of samples complying with the standards of semi-finished goods Quality control of produced samples Making finding reports containing further recommendations Basic Stages of the Metal Samples Preparation Process Milling Metal Cutting Grinding Gas Cutting Turning Basic Stages of the Plastic and Polymer Composite Samples Preparation Process Milling Metal Cutting Grinding Press tool moulding Quality Control of the Produced Samples Profiler (profilometer) Ultrasonic thickness gauge Adhesiometer Micrometer Electronic vernier calliper Distribution of Types of Testing between the Testing Machines Versatile testing machine Instron 3369 with heat chamber Types of Testing - testing of plastic and polymer tension at elevated temperatures (up to +250º С) and at lower temperatures (up to -70º С) (according to the allUnion State Standard (AUSS) 11262-80, AUSS 25.601-80, AUSS 25.603-82) - testing of plastic and polymer compression at elevated temperatures (up to +250º С) and at lower temperatures (up to -70º С) (according to AUSS 4651-82, AUSS 25.602-80); - testing of adhesion strength in case of detachment and displacement (according to AUSS 14760-69, AUSS 14759-69); - testing of detection of the metal-adhesion strength in case of exfoliation (according to AUSS 411-77); - testing of cylindrical metal samples tension at elevated temperatures (up to +250º С) and at lower temperatures (up to -70º С) (according to AUSS 1497-84, AUSS 6996-66, AUSS 9651-84, AUSS 11150-84); - testing wire stretching (according to AUSS 10446-80). Versatile testing machine Instron SATEC 600DX Types of Testing - testing of plastic and polymer samples compression at normal temperatures (according to AUSS 25.602-80, AUSS 4651-82); - slow-bend test of plastic and polymer samples at normal temperatures (according to AUSS 25.604-82, AUSS 4648-71); - testing of metal plate samples at normal temperatures (according to AUSS 1497-84, AUSS 6996-66); -testing of metal samples compression at normal temperatures (according to AUSS 25.503-97); - slow-bend test of metal samples at normal temperatures (according to AUSS 14019-2003, AUSS 6996-66); - bend-over test of metal pipes at normal temperatures (according to AUSS 3729-78); - flattening test of metal pipes at normal temperatures (according to AUSS 8695-75); - flattening test of metal samples at normal temperatures (according to AUSS 8818-73). Impact testing machine Instron SI-M1 Types of Testing - Charpy-Izod impact strength test of plastic samples at normal and lower temperatures (according to AUSS 464780, AUSS 19109-84); - Charpy-Izod impact strength test of metal samples at normal and lower temperatures (according to AUSS 945478); - Charpy non-instrumented impact strength test (according to ISO 1791:2000); Versatile testing machine Instron 8801 Types of Testing - testing on determination of the crack resistance properties of metals at a static loading (according to AUSS 25.506-85); - endurance strength test (according to AUSS 25.507-85, AUSS 25.502-79, AUSS 25.503-97); - low-cycle fatigue test (according to AUSS 25.50585); Structural Analysis of Materials Structural Analysis Sample Preparation • Dimension and direction determination of the plane under testing • Sample preparation using the Delta AbrasiMet cut-off machine, the SimpliMet 1000 automatic pressing machine and the Phoenix 4000 grinding-and-polishing machine Delta AbrasiMet SimpliMet 1000 Phoenix 4000 Structural Analysis of Materials The microprobes analysis is made on the prepared microsections with the help of the Axioimager M2m automatic upright microscope, the Axiovert 40 MAT POL inversion microscope, the Mikromet 5104 micro hardness-testing machine and the respective software. Tixomet Software System Grain point determination AUSS 5639-82 Fracture test Foliation assessment ASTM E 1268-01 Coat layers micro-hardness test Nonmetallic inclusions test Structure inhomogeneity test Macrostructure Analysis Heat-affected zone analysis Macrostructure of steel a) perpendicular to the rolling plane a) parallel to the rolling plane 33 mm Tube thickness Chemical Composition Determination ARC-MET 8000 Optical Emissive Analyzer CHEMICAL COMPOSITION – an elementwise determination of the alloying elements concentration GRADE GUIDE – based on adjustable tables, identified by the user PRINT IDENTIFICATION – comparison of the alloys based on the derived ultraviolet spectrums Nondestructive Test «VECTOR» Eddy-Current Flaw Detector ISONIC 2005 Ultrasonic Flaw Detector The Flaw Detection Methods and Options of Results Presentation of the ISONIC 2005 Ultrasonic Flaw Detector Test - standard display of the flaw detection in terms of a time scan (A-scan) Flaws display of an object in the sectional view using the ABIScan function Flaws display of an object in the plan view using the FloorMap function Flaws detection using the TOFD-method