FINAL REPORT

National Agricultural Innovation Project

(Indian Council of Agricultural Research)

Title of Sub-project:

BUSINESS PLANNING AND DEVELOPMENT UNIT

BUSINESS PLANNING AND DEVELOPMENT UNIT

CENTRAL PLANTATION CROPS RESEARCH INSTITUTE

INDIAN COUNCIL OF AGRICULTURAL RESEARCH

KASARAGOD-671124, KERALA

2013-14

Component-1

2013-14

FINAL REPORT

National Agricultural Innovation Project

(Indian Council of Agricultural Research)

BUSINESS PLANNING AND

DEVELOPMENT UNIT

CPCRI, KASARAGOD

Central Plantation Crops Research Institute

Kudlu (P.O), Kasaragod – 671124, Kerala

www.cpcri.gov.in

2013-14

Inside Cover Page

Printed on

: MARCH 2014

Component

: COMPONENT- 1

Citation

: Muralidharan K. 2013. Final report of NAIP sub project “Business

Planning and Development Unit”. CPCRI, Kasaragod

Copyright

Disclaimer

: © Indian Council of Agricultural Research (ICAR), All rights

reserved. Reproduction of material in this report for educational or

other non-commercial purposes is permitted provided the source is

fully acknowledged.

: The information presented here is contribution of the consortia

Published by

:

Edited by

: Dr. K. Muralidharan

Compiled by

: Nitin Srivastav, Augustya Barbora, Ajula Vishwanath, Trivikram

Shenoy, Baiju.C.M

Hindi translation

: Mrs. Sreelatha and Mr. Nitin Srivastav

Other Credits

: Photos: Mr. Shyama Prasad

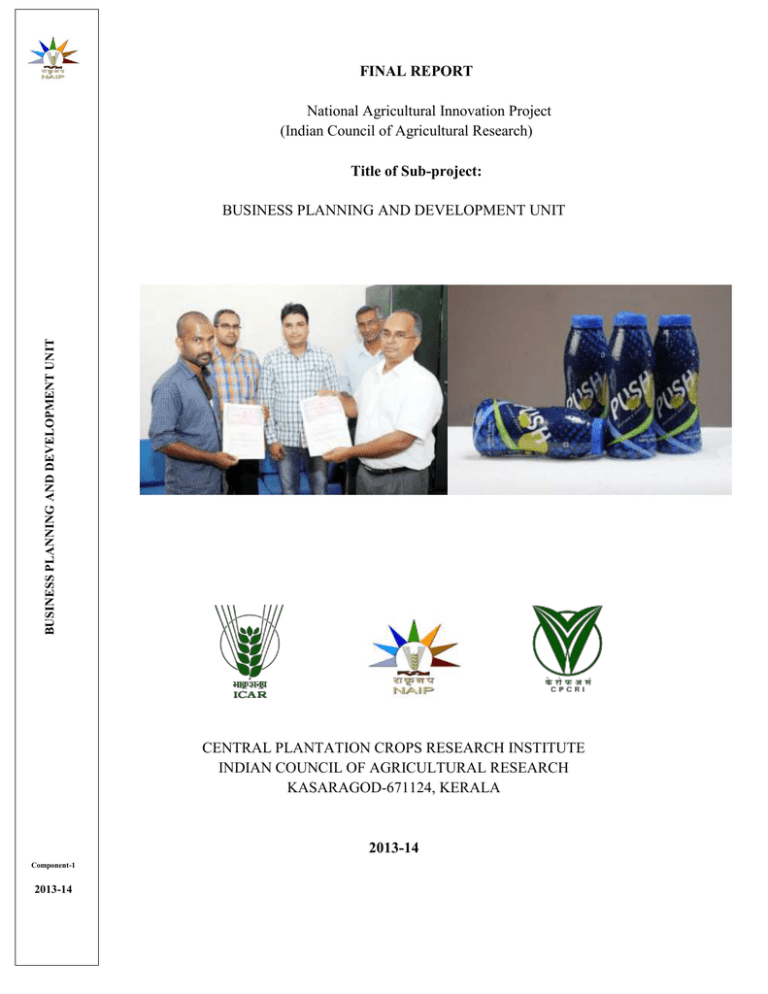

Cover page

photographs

: Coconut based products at CPCRI

Dr. George V. Thomas

Director,

Central Plantation Crops Research Institute,

Kasaragod-671124, Kerala

Phone: 04994 232333; Fax: 04994 232322

Email: directorcpcri@gmail.com,

georgethomas@yahoo.com;

www.cpcri.gov.in

______________________________________________________________________________

Printed at

CONTENTS

Foreword

Preface

Executive Summary/ Key words

Part-I: General Information of Sub-project

Part-II: Technical Details

1. Introduction

2. Overall Sub-project Objectives

3. Sub-project Technical Profile

4. Baseline Analysis

5. Research Achievements

6. Innovations

7. Process/Product/Technology Developed

8. Patents (Filed/Granted)

9. Linkages and Collaborations

10. Status on Environmental and Social Safeguard Aspects

11. Constraints, if any and Remedial Measures Taken

12. Publications

13. Media Products Developed/Disseminated

14. Meetings/Seminars/Trainings/Kisan Mela, etc. organized

15. Participation in Conference/ Meetings/Trainings/ Radio

talks, etc.

16. Foreign Trainings/Visits

17. Performance Indicators

18. Employment Generation

19. Assets Generated

20. Awards and Recognitions

21. Steps Undertaken for Post NAIP Sustainability

22. Possible Future Line of Work

23. Personnel

24. Governance, Management, Implementation and

Coordination

Part-III: Budget and its Utilization

Part-IV: Declaration

No. of pages

-by CL (1 page)

-by CPI (1 page)

3-4 pages

3-4 pages

2 pages

1 page

½ page

1 page

1 page

20-25 pages

1-2 pages

½ page

½ page

½ page

½ page

½ page

1 page

½ page

½-1 page

½-1 page

½ page

1 page

½ page

½-1 page

½-1page

½ page

½ page

1-2 pages

2-3 pages

1 page

1 page

1

Executive Summary

Executive Summary

Coconut is a vibrant and versatile palm tree grown in India and abroad. In India the major

cultivated areas being the southern part of the country. Coconut is cultivated in an area of over

1.89 million hectares in India with an annual production of 15 billion nuts and it contributes over

80,000 million rupees to the countries GDP. Owing to price fluctuation and increase in cost of

production, coconut farming has become non competitive in the recent years. Enterprise

diversification and networking for business opportunities is the key to development of the

coconut industry in India. The Business Planning and Development Unit was setup under the

NAIP component-1 as a catalyst to facilitate the coconut industry and the entrepreneurs involved

with logistic as well as technical support so that the palm crops potentials can be utilized and

diversified to the maximum level. The specific objectives of BPD unit are:

•

To promote entrepreneurship of selected business models using proven and potential

coconut value added products

•

To promote commercialization of selected technologies and their marketing

•

To provide training and consultancy in the area of coconut production and processing

technologies.

The project capitalizes on the following technologies and aims at dissemination of these

technologies for the socio economic development of the region and thrives towards sustainable

business setups for the entrepreneurs(i)

Virgin coconut oil (two methods: hot processing and fermentation)

(ii)

Coconut kernel based products (coconut chips, desiccated coconut etc.)

(iii)

Value addition to by products: Coconut water based beverages and vinegar; defatted

coconut meal based products

(iv)

Activated carbon from coconut shell

(v)

Coconut shell powder

(vi)

Coconut Milk

The project was implemented in CPCRI, Kasaragod and effective linkages were setup with

various organizations and institutions like NABARD, District Industries Centre, Coconut

Development Board, MSME, SFAC, VIA and many MOU’s were signed during the tenure.

Twenty business incubates were registered out of which two are coconut farmers producer

company, one is e-commerce portal for small farmers, two women entrepreneurs, one incubate is

already registered with another BPD unit but benefited in marketing of products from our BPD.

Sixty eight walk –ins were entertained and more than 15 entrepreneurs or farmers will register

soon. The unit has been appreciated by District Industries Centre (DIC), Kasaragod for

preparation of Detailed Project Reports (DPRs) and is now recommending to all DICs in Kerala,

with five more DPRs under preparation on request of DIC Kannur and DIC Trivandrum.

The Business Planning & Development Unit has gained good recall from local industries as well

as prospective incubates from Karnataka, Tamil Nadu , Andhra Pradesh ,Goa, Maharashtra,

Gujarat, Uttar Pradesh, Bihar and Delhi. The incubation services requested are not only in

coconut sector, but also extending to Tea, Rubber, Cocoa, Coffee, Cashew, Dairy and animal

husbandry, Fish Processing, Exports, Areca Nut, Bio-Pesticides, vegetable farming with focus on

manufacturing, processing, marketing, revenue generation and branding activities. Seven

2

Farmers Producer companies were supported out of which two were formed by initiatives taken

by unit.

India’s first Coconut Business Incubator under NAIP-ICAR, in PPP mode was setup at Pollachi,

the coconut heartland of India, with support from Vanavarayar Institute of Agriculture, a

subsidiary of famous Mahalingam group in Tamil Nadu.

The proposed incubation centre is expected to help farmers in the Pollachi Taluk of Tamil Nadu

and Chittur Taluk of Kerala with entrepreneurial innovations and commercialisation on coconut

value addition. The MoA signing was carried out in a function at VIA, in the presence of over

200 coconut farmers representing the Farmer Producers Organization.

A seminar on “Bankable technologies in coconut sector” was organized under the plan and

delegates from various banks including NABARD and DIC attended the seminar and also gave

assurance of support in form of project acceptance and help in getting it funded upon quality

submission The Activated carbon plant for coconut shell charcoal was functional during the

tenure of the project and findings were validated in due course. A separate building for the BPD

unit was also constructed under the plan which will be available for the business units who want

to startup.

Two awareness camps on various coconut technologies and value added processingswere

organised in Trivandrum and Rajamundary , which was received well by participants and fair

number of participants are willing to undergo Business incubation at BPD-CPCRI

Two Entrepreneurship Development Programs on quality and exports were conducted at

Kasaragod and Rajamundary, which will soon bear good fruits in terms of quality incubatees.

Under the BPD mandate there has been many innovation by the incubatees at CPCRI. One of the

incubate was successful in utilization of steam instead of thermal liquid in the cooker during

production of virgin coconut oil. This innovation helped in bringing down the temperature of the

VCO cooker immediately which results in a colour less oil production thereby preventing change

in undesired colour of the oil.

Another incubate of BPD-CPCRI was successful in use of bio-preservative for a packaged

coconut water beverage. Innovative means of marketing the agricultural produce was also

developed by ecommerce means by one of the incubatees of the unit.

The Business Planning & Development Unit at CPCRI, Kasaragod was established with initial

financial outlay of Rs 160 lakhs and out of which Rs 128 Lakhs have been utilised till date. One

Incubatee received export order from Italy worth Rs 10 lakhs and another is awaiting the Letter

of Credit from the buyer.

Number of exhibitions, seminars ,mela were attended to promote products of the incubatees of

BPD.

3

1.

2.

3.

4.

5.

6.

7.

8.

Part-I: General Information of Sub-project

Title of the sub-project: BUSINESS PLANNING AND DEVELOPMENT UNIT

Sub-project code:

Component: COMPONENT 1

Date of sanction of sub-project: 21st May 2013

Date of completion:31st March 2014

Extension if granted

Total sanctioned amount for the sub-project: 160.16 lakhs

Total expenditure of the sub-project: 128.95 lakhs

1. Consortium leader:

Dr. George V. Thomas

Director,

Central Plantation Crops Research Institute,

Kasaragod-671124, Kerala

Phone: 04994 232333; Fax: 04994 232322

Email: directorcpcri@gmail.com,

georgethomas@yahoo.com;

www.cpcri.gov.in

2. List of consortium partners:

Name of CPI/ CCPI

with designation

CPI

Dr. K.Muralidharan

Name of organization and

Duration

Budget

(` Lakhs)

address, phone & fax, email

(From-To)

Head, Social Science Dept.

21/5/13

to 160.16

CPCRI, Kasaragod-671124

31/3/14

kmurali.cpcri@gmail.com

CPI-Consortia Principal Investigator; CCPI-Consortia Co-Principal Investigator

3. Statement of budget released and utilization partner-wise (` in Lakhs):

CPI/ CCPI Name,

Total

Fund released

Fund utilized

designation & address)

budget

(up to closing

(up to closing date)

sanctione

date)

d

128.95lakhs

128.95lakhs

Dr.K.Muralidharan

CPI

160.16

(Feb17

2014)

(Feb17 2014)

Head, Social Science Dept.

lakhs

CPCRI, Kasaragod-671124

kmurali.cpcri@gmail.com

Total

160.16

128.95

128.95

CPI-Consortia Principal Investigator; CCPI-Consortia Co-Principal Investigator

4

Part-II: Technical Details

1. Introduction

CPCRI has developed number of technologies having commercial importance. The institute has

transferred some of the technologies to entrepreneurs in the past. But it was observed that

entrepreneurs faced many constraints with regard to marketing, branding, availing credit,

technology backstop etc. while establishing their business. Many startup ventures were also

closed in the initial years itself for one or other reasons. To equip the startup entrepreneurs to

reduce their learning curve it was proposed to establish a Business Planning and Development

Unit (BPD) at CPCRI as part of National Agriculture Innovative Project (NAIP). Accordingly

NAIP sanctioned the project with the financial outlay of Rs.160.16 lakhs vide sanction no.

F.No.30 (1)2013/CPCRI/BPD/NAIP/O&M dated 21 May 2013.

The primary mandate of the BPD Unit, CPCRI is to promote Agribusiness in coconut, areca nut

and cocoa. With area coverage of over 1.89 million hectare and an annual production of over 15

billion nuts, the coconut sector provides ample opportunities for agribusiness. Every part of

coconut has a use and over 40 coconut products are traded globally. But in India the trade is

confined to copra, coconut oil and desiccated coconut.

The distribution of area under coconut cultivation shows that the major portion of coconut

production in the country rests with the western plains and Ghats regions comprising the states of

Kerala, Karnataka and Maharashtra followed Eastern coast plain and hilly regions comprising

Andhra Pradesh, Orissa, Tamil Nadu and Pondicherry. The entire quantum of coconuts produced

is not sold in the market.

The farmers generally retain a portion of their farm produce for

meeting seed requirement, direct consumption and payment of climber’s wages etc.

The

quantity of coconut converted to copra for milling purpose varies from state to state depending

upon the consumption pattern of coconut and its products. The Export and Import of coconut

products reveal grim situation in the country. However, it has been reported that India’s exports

earning from coconut products is increasing at the compound growth rate of 20.71% per annum

and the import of coconut and its products increases the trade deficit in the export earning of the

country. To make the country competitive globally, capacity building among small farmers,

Famer Producers Group and prospective entrepreneurs are to be attempted. Business Planning

5

and Deployment Unit, CPCRI would tap innovations in the sector, conceptualize business

opportunities, market validate and commercialize by capitalizing on its strong network among

the stakeholders.

2. Overall Sub-project Objectives

The Indian coconut sector has to be strengthened to withstand the competition from other

countries by increasing productivity and value addition. The price of coconut in India is

largely dependent on trade of coconut oil, which often experience volatile price fluctuations.

Broadening of coconut trade to other value added business would bring price stability, which

will be achieved by utilizing divergent coconut technologies.

Business Planning and

Development Unit, CPCRI, Kasaragod was set up to hasten the diversified growth of coconut

industry in India. The project has the following specific objectives.

To promote entrepreneurship of selected business models using proven and potential

coconut value added products

To promote commercialization of selected technologies and their marketing

To provide training and consultancy in plantation crops research and business

development.

3. Sub-project Technical Profile

Indicate briefly objective-wise work plan, monitoring indicators, expected output and

expected outcome)

3.1. To promote entrepreneurship of selected business models using proven and

potential coconut value added products

Work plan

Registration of incubatees and

graduation

Monitoring

indicators

Number of

incubatees

registered;

number of

technologies

sourced

Output

Outcome

20 incubatees

registered.

One Technology

from another BPD

commercialized.

6 Coconut

technology

sourced from

CPCRI,

10 incubatees

started operations.

One DPR approved

by DIC, Kasaragod

for land grant and

funding. Export

order worth Rs.9.5

lakhs was finalized

for an incubatee.

6

Popularization of technologies

Number of

technologies

popularized

Establishment of linkage

among Research, Development,

aligned government

departments, and credit

institutions.

Conducting

workshops;

participation in

meetings etc.

Connected to Traditional

coconut trade channel to

develop business for incubatees

organically.

Market survey

IIHR,CDB/DFRL. Helped 2

incubatees to create

own brands

Eight technologies:

Conducted 2

VCO (hot and

Business

fermented); Chips;

awareness

DC; Activated

programmes

carbon; coconut

Participated in 8

water beverages;

exhibitions

shell powder; palm

Prepared and

sugar.

distributed

literatures/brochur

es.

Disseminated 6

technologies to

more than 18

entrepreneurs.

Four workshops

conducted (Launching;

Bankers; stakeholders of

Neera; FPO)

Meeting with 8 agencies

(DIC, Coconut

Development Board, Coir

Board, NABARD, SFAC,

FORTIS, VIA

Surveyed Coimbatore,

Erode, Pollachi,Varanasi,

Rajmundary, Nagercoil,

Kannur,

Kasaragod,Mysore

districts for coconut .

Conducting EDP

Number of EDPs

conducted

One EDP conducted at

Kasaragod and One EDP

at Rajmundary

The BPD Unit,

CPCRI, Kasaragod

was recognized as

a credible source

for technology,

business plans, and

other incubation

services.

The credit

institutions

recommend

entrepreneurs to

get projects

prepared by BPD

Unit, CPCRI.

Connection

established with

among top coconut

traders in the area

surveyed

The participants

benefitted with

information on

regulations, quality

standards, and

marketing.

7

Mentoring

Number of

68 entrepreneurs; 6

entrepreneurs/FPO FPOs/community based

s mentored

organizations

Research and technology

backstopping

Establishing agribusiness

incubation centre at CPCRI

Number of

services provided

Establishing the

centre and equip

with facilities

Establish

processing

facilities for the

FPOs

Establishing coconut

incubation centre for FPO

Three incubatees placed

their demand

Work will be completed

by March 2014

Signed MOU with VIA,

Pollachi for establishing

coconut incubation centre

in PPP mode

The participants

were also guided in

general aspects of

Business Start-ups.

18 entrepreneurs

identified business;

Publicity for BPDCPCRI as genuine

centre for Business

Incubation in

Plantation Crops

Technologies are

being evolved.

Building

construction in

progress.

Building

construction in

progress

FPO formed,

legalization in final

stages.

Traders connected

to FPO, with

annual trade

assured of 1 Crore

Rupees for coconut

and coir based

products.

3.2. To promote commercialization of selected technologies and their marketing

Work plan

Preparation of business

plans for commercialization

of coconut technologies

Networking and establishing

of market channels

Monitoring

indicators

Number of

business plans

prepared

Output

Outcome

Six business plans

prepared

Number of

channels

established

Five trade channels

(Traditional, ecommerce, modern

Enquiries for

preparation of

business plans from

entrepreneurs, credit

institutions, and

government

departments

Increase in revenue

for the incubatees;

product exposure

8

retail, health care

retail, export)

3.3.

and branding.

Revenue generation

for BPD Unit

To provide training and consultancy in plantation crops research and business

development.

Work plan

Conduct training

programmes on coconut

technologies

Providing consultancy on

agribusiness management

Monitoring

indicators

Number of training

programmes

Output

Outcome

Five training

programmes

conducted;

Presentations were

also made in

programmes

organized by other

agencies like CDB,

Coir Board, SFAC.

Number of services

provided

Two beneficiaries

Skill development of

participants;

creation of

awareness for value

added coconut

technologies, and

backstopping for

technologies, scope

of BPD explained

for their Business

Incubation.

Enhanced revenue

for the clients.

Backup and

assistance

Brand Leveraging

for BPD-CPCRI

4. Baseline Analysis

The

major

socio-economic

feature

of

coconut farming in India

is

that

the crop is

predominantly cultivated in small and marginal holding and with medium resource to poor farm

environment having less marketable surplus. It has been reported that the national average

productivity of coconut in India is very low i.e. around 40 nuts per palm per year.

The low

productivity of coconut crop in the country has been on account of several reasons, i.e. lack of

adoption of scientific cultivation practices to enhance productivity, scientific cultivation

practices helps in bringing down the cost of production.

More than 90% area under and production of coconut in India is confined to the four southern

states viz., Kerala, Tamil Nadu, Karnataka and Andhra Pradesh. There is a distinct difference in

the pattern of distribution of this crop in the country: Except in Kerala, coconut is not grown

9

contiguously in other states but limited to only congenial belts accounting to an insignificant

portion of the total arable agricultural area.

The entire coconut production in the country is utilized for internal consumption, and only very

little quantity of coconut products is exported to other countries. The internal consumption

comprises mainly for oil extraction, direct consumption for edible purpose, religious offerings

and retention for seed purpose.

Till recently copra making and processing (for coconut oil) was the dominant commercial

activities in the sector. Off late desiccated coconut is also catching the attention of consumers.

Owing to scientific reports on coconut as a healthy food and growing demand for natural food,

other products like Virgin Coconut Oil, coconut chips, coconut milk, and tender coconut water

(natural as well as packaged), are also finding increased consumer base.

5. Research Achievements with Summary

5.1. Preparation of business plans

Based on primary data collected from entrepreneurs and/or also using the data available at

CPCRI, Kasaragod, business plans for Virgin Coconut Oil (VCO), coconut chips, unfermented

coconut sap, and palm sugar were prepared. For preparation of business plans of Desiccated

Coconut (DC), and coconut shell powder, data collected from entrepreneurs, by personal

interview as well as secondary data were used.

5.1.1. Business plan for VCO

Virgin Coconut Oil technology is exclusively developed and marketed in India by Central

Plantation Crops Research Institute, Kasaragod Kerala. The entrepreneur will be requiring 2

cents of land with good road connectivity and proximity to coconut procurement area.

The financial analysis of the investment for VCO unit indicated that the

project has a margin money component of 30% with the Rate of Interest on

term loan and working capital as 12% and 10% respectively. There is

enough Profit Margin on the product at a selling of Rs.450/l.

10

For this project, the main financial indicators calculated for a period of 10 years of the

investment are as under:

Net Present Value Rs. 9.65 Lacs

Internal Rate of Return (IRR) = 20 %

Benefit Cost Ratio ( BCR) = 1.09

Principle amount + interest repayment time = 6-8 years

5.1.2. Coconut chips

Coconut chips are prepared by removing the moisture content of the coconut kernel partially by

osmotic dehydration using osmotic media. The dehydrated coconut chips is

in ready-to-eat form and can be used as snacks. It could also be used at any

time just like fresh kernel after rehydration of the chips.

The entrepreneur will be requiring 2 cents of land with good road

connectivity and proximity to coconut procurement area. He or she will be

provided with 25% subsidy and has to provide 30% of initial project cost as

margin money. Rest 45% of the project cost has to be sourced through

banks, funding agencies or angel investors. The project has a payback

period of 6 years.

Detailed project report for coconut chips was prepared and the financial

indicators are as follows:

Investment cost of 16 lacs

NPV of 5.04 lac,

IRR equal to 19%

BCR being 1.06.

5.1.3. Unfermented coconut sap

Unfermented coconut sap (Neera) is obtained by tapping the unopened spadix/inflorescence of

the coconut palm. Is highly nutritive and a good digestive agent. Fresh neera is sweet, oysterwhite and translucent, with a nearly neutral pH. It is a rich source of ascorbic acid and

carbohydrate. Contains minerals, proteins, high amounts of essential elements such as N, P, K,

Mg and micronutrients (B, Zn, Fe, Cu).

The detailed project report for fresh coconut sap was made and it was found that by harvesting

sap from 150 trees per day, there is a production of 82125litres per year. There is a 100%

11

recovery for the final product which can be sold @ Rs.10/200ml. With these economic figures

the unit can fetch a net income of 10.68lakhs.

5.1.4. Coconut palm sugar

Obtained by boiling freshly harvested toddy/sap in moderate heat to evaporate the water. Has a

high potential for use as natural sweetener. Contains more amount of nitrogen, phosphorus,

potassium, magnesium, sodium, chlorine, sulfur, boron, zinc and copper compared to refined

cane or brown sugar. Hence, it is more nutritious than commonly used sugar products. Good

for both diabetics and non-diabetics. Has a low glycemic index (GI). Coconut palm sugar helps

in preventing obesity.

The detailed project report for palm sugar was made and it was found that by harvesting sap

from 150 trees per day, there is a production of 82125litres per year. There is a 15% recovery for

the final product which can be sold @ Rs.350/kg. With these economic figures the unit can fetch

a net income of 10lakhs.

5.1.5. Desiccated coconut

Desiccated coconut is coconut meat which has been shredded or flaked and then dried to remove

as much moisture as possible. There are a number of different styles of desiccated coconut used

around the world, and availability of this coconut product varies, depending on the region where

one is shopping. First step in the manufacture of desiccated coconut is the selection of coconuts.

The quality of desiccated coconut depends upon the quality of coconuts used. Fully matured

coconuts of about 12 months are used for the preparation of desiccated coconut. Fully matured

nuts are stored with the husk for about one month so that the water inside the kernels is absorbed.

This also facilitates coconut kernels to get separated from shell walls. The coconuts are dehusked

and their shells are removed. The brown portion of nuts called testa is removed by scrapping it

off. About 10-15% of the kernel goes as paring by this process. These parings can be pressed out

after drying to get oil which can be used for soap making. De-shelled coconuts are broken into

pieces, washed properly and disintegrated into powders of various grades. The powder is then

dried in a drier by spreading it out uniformly in trays. The temperature in the drying chamber is

maintained at about 180 F and the powder is stirred occasionally during the drying process to

ensure uniform drying. Great care should be taken during drying. When powder is dried, it is

12

cooled and passed through a vibratory screen having different sizes (12, 14 and 16 mesh). The

segregated material is packed in oil proof, moisture proof polythene lined plywood boxes of 25

kg. It may also be packed in poly bags of 250 gm., 500 gm. and 1kg for retail sale. During the

process of manufacturing desiccated coconut, a number of byproducts such as coconut shell,

parings, and husks are obtained which may be converted into various items of great importance.

It has been worked out that 100 kg. of desiccated coconut is obtained from 1000 coconuts.

Breakeven point = 20147.43

Breakeven sales= 23.16lakhs

NPV= 2.30crores

IRR= 25%

Benefit cost ratio= 1.11

5.1.6. Coconut shell powder

Coconut shell powder is manufactured from residue shells of the matured coconuts. The

manufacture of coconut shell powder is not an organized industry in India. The product finds

extensive use in plywood and laminated board industry as a phenolic extruder and as filler in

synthetic resin glues, mosquito coils, break liners and the manufacture of agarbathis. Coconut

shell powder is preferred to be an alternate material available in the market such as bark powder,

furfural and peanut shell powder because of its uniformity in quality and chemical composition,

better properties in respect of water absorption and resistance to fungal attack.

Sales Realisation for the first year when the plant capacity attains 75% is Rs 320.59 lakhs. Net

Profit for the first year of operation is 2.75 Lakhs after Tax. The profitability is improved when

the capacity is increased and the average net profit ratio is 3.43 %. Internal Rate of Return for the

Project is 18 % and average Return on Capital employed over a period of 10 years of the project

is 12%. The Project breaks even at 86% at the first year. Debt Service Coverage Ratio during the

first seven years average to 1.92. All the above indicators support the viability of the Project.

Net profit 1st year at 75% efficiency= Rs.320.59lakhs

Internal Rate of Return= 18%

Payback period= 10years

13

5.2 Identified trade channel for coconut

There are huge areas of coconut plantation in southern part of India, although the prices for

coconut is determined by the trade of coconut oil. It was very important to broaden the horizons

of coconut trade in the country and the only way to do it was by involving more and more people

in coconut processing and introducing value added products and trade channels. BPD was

instrumental in introducing new products to the industry and thereby involving new entrants in

the market who were involved in value addition. Hence the coconut trade was channelized in an

organized manner between southern part of the country and the northern and western regions of

India. E-commerce were utilized to channelize the coconut produced and buying and selling was

done online.

5.3 Identified trade channels for other crops

Apart from coconut, BPD has strived towards developing a trade channel for other crops like tea,

cocoa and arecanut. A trade channel for tea is in the process of establishment between Assam

and Kerala. The tea from Assam would be channelized and distributed into the geographies of

the southern states. A trade channel for arecanut is in the process of establishment in Kerala

where the produce will be channelized for value addition.

5.4 Formation of FPO

Two FPOs where setup under the BPD unit in Kerala, Tamil Nadu and other places in order to

assist the coconut farmers in channelizing and locating their produce. The FPOs will be

instrumental in maintaining a steady price for coconut and also an assured income for the group.

It will bring assured supply of resources and raw material for the group and it is believed that

such kind of organized groups for farmers are beneficial in uplifting their socio economic

condition.

5.4 International Presence

It was found that the International Energy Drink segment is still missing the natural energy drink

products like tender coconut water, more people are gradually realizing the ill-effects of

14

sweetened carbonated beverages and turning to natural alternatives to refresh themselves. One

such opportunity was found out in European Union, first in Italy and second in Serbia and

Germany. The products have already been shipped to Italy, and expecting good response of

sampling activity in Belgrade. These two opportunities itself can provide such an opportunity

that within two months the annual produced of our Incubatee can be consumed, thus providing

the necessary impetus and encouragement to other fellow incubatees

International market for Virgin Coconut Oil was researched and Belgium was found to be most

promising, currently the negotiations are under process between our incubatee and the buyer

based in UK / Belgium .

Launch workshop of the project on 7 Jun 2013

Sri. Apoorvanathan, CGM, NABARD

addressing the bankers

Signing of MOU between CPCRI and VIA for

establishing coconut incubation centre at

Pollachi

Signing of the first MOU between an

entrepreneur and CPCRI

15

Meeting organized at Pollachi in connection

with the formation of FPO

Stakeholders meet on ‘business opportunities

of neera’

Mass media used for publicity

Participation in exhibitions

6. Innovations

One of the incubates improvised and successfully utilized steam instead of thermal liquid for

indirect heating of VCO cooker. This innovation helped in bringing down the temperature of the

VCO cooker quickly so that the color of the product from different batches oil is uniform.

Thereby the byproducts were utilized and saved for further purposes.

Another incubate of BPD-CPCRI was successful in use of bio-preservative for packaged tender

coconut water benefitted him to receive export orders as well as market in Gujarat , Delhi, Orissa

and Uttar Pradesh. The incubatee has almost reached the Maximum production capacity of the

16

plant, there by finding scope to increase time efficiency in processing , hence re-working the

capacity of the plant to new high level.

7. Process/ Product/Technology Developed

(List partner-wise major Process/ Product/Technology developed and their outcome in

quantifiable terms)

Nil

8. Patents (Filed/Granted): Nil

S.

No.

Title of Patent

Inventor(s) (Name &

Address)

Filed/Published/

Granted

(No./Date)

Responsible

Partner

9. Linkages and Collaborations

S. No.

1.

Linkages developed

(Name & Address of Organization)

2.

District industries centers of Kasaragod,

Malappuram, Kozhikod & Kannur

NABARD-Kerala, Tamil Nadu

3.

District Lead Bank, Kasaragod

4.

Coconut Development Board

5.

6.

Vanavarayar Institute of Agriculture,

Pollachi, Coimbatore

All banks in Kasaragod district

7.

Coir Board, India-Kochi

8.

Fortis Healthcare-New Delhi

9.

SFAC, Kerala

10.

Other BPDs (ICRISAT, IISR, IIHR,

Date/Period

From-To

Responsible Partner

June 2013Present

June 2013Present

June 2013Present

June 2013Present

July 2013Present

October 2013Present

October 2013Present

October 2013 Present

January 2014Present

September

CPCRI, Kasaragod

-do-do-do-do-do-do-do-do-do17

11.

12

13

14

15

16

17

18

19

20

21

22

23

IIVR, IVRI, NDRI, GAU, TNAU)

Farmer Producer Organization – Seven

FPO in Kasaragod, Kannur, Kojhikode,

Alleppy, Mysore, Pollachi

Indian Consulate, Milan( Italy )

Italian Embassy, New Delhi

Italian Trade Platform, Mumbai

Agri-Input Distributor in Bihar, Uttar

Pradesh , Tamil Nadu for an existing

incubatee of BPD-IIHR

Consultant- Jakarta Future Exchanges,

To initiate our plantation Crops Business

Incubation Centre in Indonesia to cater

South Asia Pacific- Djakarta

Belgrade Music Festival- 5,00,000

footfall event, Great opportunity for our

incubatee in Packed tender coconut water

Modern Retail- Big Bazaar, Namdhari,

Café Coffee Day-Mumbai, Bangalore

Uttar Pradesh Government Procurement

Department –Agri Inputs, lucknow

Coconut Traders- Varanasi, Rajmundary,

Coimbatore, Karur, Erode, Kannur

NRIs from Goa, Kerala, Karnataka,

Tamil Nadu currently in USA, Dubai and

Africa

Coconut Processing Plant Manufacturers

in Salem

World Bank, Sri Lanka Office- New

Delhi

Entrepreneurs from Canada , Korea and

China

Government of Uttaranchal, Ministry of

Education

2013- Present

October 2013Present

-do-

November

2013- Present

-do-

October 2013Present

-do-

December

2013-Present

-do-

January 2014Present

-do-

December

2013-Present

February 2013Present

October 2013Present

September 2013

- Present

-do-

November 2013

– Present

October 2013 Present

January 2014 Present

November 2013

– Present

-do-

-do-do-do-

-do-do-do-

10. Status on Environmental and Social Safeguard Framework

(Please see NAIP website for clarity on the subject)

Nil

11. Constraints, if any and Remedial Measures Taken

18

Nil

12. Publications (As per format of citation in Indian Journal of Agricultural Sciences)

A.

Research papers in peer reviewed journals

S.

No.

B.

S.

No.

Authors, Title of the paper,

Name of Journal, Year, Vol. & Page No.

NAAS

Ratings

Responsible

Partner

Books/ Book chapters/ Abstracts/ Popular articles, Brochures, etc.

Authors, Title of the papers

Name of Book/ Seminar/ Proceedings/Journal, Publisher,

Year, Page No.

Responsible Partner

13. Media Products Developed/Disseminated

S.

No.

1

2

3

4

5

CD, Bulletins, Brochures,

etc. (Year wise)

Leaflet for TNAU exhibition

English Posters for TNAU

exhibition

English Posters for SYMSAC

VIII exhibition, Madikeri

Hindi Posters for Kissan 2013

exhibition at Pune

Hindi and English Bilingual

Leaflet for Kisan 2013, Pune

No. of Copies

Distribution

200

5

Responsible

Partner

CPCRI

CPCRI

3

CPCRI

3

CPCRI

10000

CPCRI

14. Meetings/Seminars/Trainings/Kisan Mela, etc. organized

S.

Details of

Duration

No. of

Budget

No.

Meetings/Seminars/

(From-To)

Personn

Trainings, etc.

el

Trained

th

1. Introductory

7 JUNE’13

20

workshop on

coconut technology

Organizer

(Name & Address)

CPCRI

19

2. Coconut Stake

Holders Meeting

held at VIA Pollachi

3. Stakeholder’s

interface programme

on “Production and

Marketing of Neera

as a health drink:

Prospects

and

Challenges

on

4. Workshop

Bankable

Technologies

in

Coconut Sector

5. Awareness camp and

training programme

on

coconut

technology

at

pollachi

Signing

6. MoU

programme between

CPCRI and VIA

7. Formation meeting

conducted for

coconut farmers

FPO of Kottur

Malayandipattinam

in Tamil Nadu

8. Formation meeting

conducted for

coconut farmers

FPO of

Meenakshipuram in

Kerala

9. Business Awareness

Camp at Trivandrum

10. Formation meeting

conducted for

coconut farmers

from Kottur

Malayandipattinam

in Tamil Nadu

11. Entrepreneurship

Development

Program

12. Business Awareness

16 August, 2013

27

VIA, Pollachi, CPCRI

02

September,2013

38

CPCRI

08 October,

2013

26

CPCRI

30th November

2013

200

CPCRI

30th November

2013

200

CPCRI

28th January

2014

15

CPCRI

5th February

2014

30

CPCRI

7th Feb 2014

100

CPCRI

28th Jan 2014

15

CPCRI

3rd March 2014

20

CPCRI,Kasaragod

10th March 2014

100

CPCRI

20

Camp at

Rajamundry

13. Entrepreneurship

Development

Program

14. Agri –Business

Export web

enabled( video

conferencing)

Workshop

20th March 2014

20

Rajmundary, Andhra

Pradesh

28th March 2014

30

CPCRI

15. Participation in Conference/ Meetings/Trainings/ Radio talks, etc.

S.

No.

Duration

1.

9-12 July, 2013

2.

12-14 August, 2013

3.

1-2 September, 2013

Details of

Meetings/Seminars/

Trainings/Radio

talk, etc.(Name

&Address)

Organized

by

CTCRI, Trivandrum

in completion of

their 50 years

Training on various

aspects of EDP for

BPD

Exhibition at

TNAU, Coimbatore

in connection with

World Coconut Day

Vibrant Gujarat

Agricultural Summit

4.

9-10 September, 2013

5.

3-5 October, 2013

Exhibition

“Machathalon 2013”

6.

24-26 October, 2013

7.

27-29 November, 2013

Orientation

Workshop and

Hands on training

programme for BPD

units in NARS SYMSAC VII

Organizer: CIFT,

Cochin

Venue

Participant

(Name & Address)

Mascot Hotel,

Trivandrum

CIFT, Cochin

TNAU,

Coimbatore

Gandhinagar,

Gujarat

LBS College

of

Engineering,

Kasaragod

NAARM,

Hyderabad

Hotel Crystal

Court,

Madikeri,

Karnataka

21

8.

9

10

13-17 December, 2013

th

th

15 January -19

January 2014

9th February – 13th

February 2014

Exhibition Kissan,

2013

Exhibition

Kasaragod Fest 2014

Krishi Vasant 2014,

Pune

Kasaragod

Central

institute for

Cotton

Research,Nag

pur ,

Maharashtra

16. Foreign Trainings/Visits:

S.

No.

Name,

Designation,

Address of

the Person

Visit/Training/Seminar

its Place, Organization

and Duration (FromTo)

Dates of

Seminar

Delivered and

Report

Submitted on

Return

Follow up

Action

Total Cost

(`)

17. Performance Indicators

(As per the enclosed format in Appendix-1: Component-wise; and Sub-component-wise)

S. No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Indicator

No. of production technologies released and/or adopted

No. of processing technologies released and/or adopted

Number of technologies/products commercialized based on

NAIP research

No. of new rural industries/enterprises established/ upgraded

No. of product groups for which quality grades developed and

agreed

Total no. of private sector organizations (including NGOs)

participating in consortium

No. of farmers involved in consortia activities

Total number of farmers’ group developed for marketing and

processing

Number of patent/intellectual property protection applications

filed based on NAIP research

Number

of

patents/intellectual

property

protections

granted/published based on NAIP research

Number of scientists trained overseas in the frontier areas of

Total Numbers

1

Nil

1

1

4

200

2

Nil

Nil

Nil

22

13.

14.

15.

science

Number of scientists trained overseas in consortium-based

subject areas

No. of scientists participated in conference/seminar etc. abroad

Success stories

Incremental employment generated (person days/year/HH)

17.

Increase in income of participating households (Rs. Per annum)

Nil

19.

20.

Number of novel tools/protocols/methodologies developed

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Nil

12.

Nil

Nil

5

Nil

16.

18.

Nil

Nil

Nil

Nil

Nil

Nil

1

6

Nil

10,200

2

18. Employment Generation (man-days/year)

S. No.

1.

Type of Employment

Generation

Employment of 200 farmers in

the

Farmer

Producer

Organisation in Pollachi

Employment Generation up

to End of Sub-project

200

Responsible

Partner

CPCRI,VIA

19. Assets Generated

(i)

Equipment

23

S.

No.

1.

Equipments

for

VCO

processing

Equipments

for

chips

processing

Equipments for desiccated

coconut

Laptop,

Desktop,

Photocopying Machine

2.

3.

4.

(ii)

S.

No.

1.

(iii)

S. No.

1.

2.

3.

4.

5.

6.

7.

Name of the Equipment

with Manufacturers

Name, Model and Sr. No.

Year of

Purchase

Total cost

(`)

Responsible

Partner

2013

17,67,549.50 CPCRI

2013

6,12,820

CPCRI

2013

26,93,250

CPCRI

2013

2,58,982

CPCRI

Works

Particulars of the Work,

Year of

Name and Address of

Work Done

Agency Awarded the

Work

Construction

of

BPD 2013-14

building

with

electrification

Revenue Generated

Source of Revenue

Mr. V.S. Nayak

Vishal Enterprise, Thindal, Erode,

Tamil Nadu

Mr. MA Haris

Mullaria House, PO Mullaria,

Kasaragod

Mr. Kunhabdullah A.

Nafeesa

Manzil,

Padne,

Kadappuram, Kasaragod

Mr. Joy Cyriac, Chunnus Products,

Muttithadi, Trissur, Kerala

Mr.

AM

Abdul

Kader,

Chottumkuzhi, Hidiyath Nagar,

Kasaragod

Mr. Mohammed Sinan

PO Adhur, Kasaragod

VS Shankar Bhatt

Total

Cost

(`)

Responsible

Partner

40,20,865 Sri. TM Faize, Sri.

Sajith Lal, CPCRI

Year

Total amount

(`)

Responsible

Partner

21/10/13

2000

CPCRI

28/10/13

2000

CPCRI

28/10/13

2000

CPCRI

12/11/13

2000

CPCRI

9/12/13

2000

CPCRI

24/12/13

2000

CPCRI

7/1/14

2000

CPCRI

24

8.

SHAMATHMIKA, Vadya, PO

Kabaka, Puttur Taluk, Karnataka

Mrs. Arunima Krishnan

Kasaragod

Mr. Madhu K.C, Chinku Sweets,

Thalasary

Mr.

Safwan

M.M,Global

Associates,

Manjeshwar,

Kasaragod

Mr. Samuel P.E, Wayanad

13/1/14

2000

CPCRI

27/1/14

2000

CPCRI

30/1/14

2000

CPCRI

31/1/14

2000

CPCRI

Mr. P Nagendra Babu, Hi7 Agri 1/2/14

Bio, Bangalore

Mr.

Thalicherry

Govindam, 4/2/14

Kanhangad

Mr. Damodaran M, Kannur

10/2/14

2000

CPCRI

2000

CPCRI

2000

CPCRI

2000

CPCRI

16.

Mr. Yaseer T, Tenhippalam, 11/2/14

Calicut

Mr. Kaleshan T,Puthiyangadi

11/2/14

2000

CPCRI

17.

Mr. Siby Mathew, Kasaragod

2000

CPCRI

18.

Mr.

Baiju

Nedumkery, 14/2/14

KAVPRAD,Ernakulam

Meenakshipuram FPO

January

2014

Malayandipatnam FPO

January

2014

TOTAL

2000

CPCRI

Revenue

sharing Plan

Revenue

Sharing Plan

36,000/-

Formed by CPCRI

9.

10.

11.

12.

13.

14.

15.

19.

20.

12/2/14

Formed by CPCRI

20. Awards and Recognitions

S. No.

Name,

Designation,

Address of

the Person

Award/ Recognition (with

Date)

1.

Dr. K.

Muralidharan

Award for setting up India’s

first Coconut Business

Incubator

Institution/

Society

Facilitating

(Name &

Address)

ABIICRISAT

Responsible Partner

ICRISAT

25

21. Steps Undertaken for Post NAIP Sustainability

a) Establishment of Coconut Business Incubator in PPP mode with Vanavarayar Institute of

Agriculture, Pollachi , with 30:70 profit sharing ratio in between CPCRI : VIA.

b) Regularization of BPD staff under CPCRI.

c) Registration of Incubates and revenue sharing ( 1% annually ) in between Incubatee and

CPCRI in form of MoA.

d) Uptake of Short term consultancy services for companies, entrepreneurs, social groups

and incubates.

e) Preparation of Detailed Project Report for District Industries Centres, Kerala.

f) Liasoning with credit agencies like Nationalised Banks to provide them market ready

business concepts and prepared entrepreneurs for loans.

g) Start of Lease manufacturing facility for value added coconut products in CPCRI

campus.

22. Possible Future Line of Work

a) Consultancy Project for Private companies operating in (Agri) Food processing,

Marketing , Branding, Revenue channel Establishment, Market survey and penetration.

b) Establishment of self sustaining sales outlet in New Delhi, Mumbai, Chennai, Bangalore

and Hyderabad for display and sales of products from incubates of Business Planning &

Development Unit-CPCRI.

c) Initiation of Business Incubation services for Tea, Coffee , Cashew , Rubber in India.

d) Establishment of Agri-Business Incubation units in SAARC countries, European Union,

Japan, Korea, Dubai, Indonesia and Singapore.

e) Marketing support for all other Business Planning & Development units under ICARNAIP.

f) Commercialization of NAIP generated technologies.

23. Personnel

(Staff of Lead Centre & Partner-wise, their Name, Designation, Discipline and Duration)

From – To (DD/MM/YYYY)

Research Management (CL)

1. DR. GEORGE V. THOMAS

Scientific (CPI, CCPI, others)

2. DR. K. MURALIDHARAN

3. DR. C. THAMBAN

4. DR. AC MATHEW

5. DR. K. HEBBAR

6. DR. MURLI GOPAL

21/5/2013 - Present

21/5/2013 - Present

21/5/2013 - Present

21/5/2013 - Present

21/5/2013 - Present

21/5/2013 - Present

26

7. MR.S. JAYASHEKHAR

Contractual

8. NITIN SRIVASTAV, BM

9. AUGUSTYA BARBORA, RA

10. AJULA VISHWANATH

11. TRIVIKRAM SHENOY

12. ASHOK KUMAR

21/5/2013 - Present

24/8/13-Present

13/8/13- Present

5/8/13- Present

1/8/13- Present

15/10/13- Present

24. Governance, Management, Implementation and Coordination

A. Composition of the various committees (CIC, CAC, CMU, etc.)

S. No.

Committee Name

Chairm

Members

an

(From-To)

(FromTo)

1.

CIC

IMPLEMENTATION

1)Nitin Srivastav, BM

COMMITTEE

2)Augustya Barbora, RA

3)Ajula Vishwanath, RA

4)Trivikram Shenoy, Pilot Plant

Supervisor

2.

CAC

ADVISORY BOARD

1)Dr. K. Muralidharan, Head,Dept of SS

2)Dr. A.C. Mathew, Senior Scientist

3) Dr. K. Balachandra Hebbar, Head,

Division of PB & PHT

4) Dr. C. Thamban, Principal Scientist

(Agrl Extension)

5) Dr. Murali Gopal, Principal Scientist

Microbiology

6) Mr. S. Jayasekhar, Scientist (SS)

3.

CMU

MANAGEMENT

1) Dr. George V. Thomas, Director,

CPCRI

2) Dr. K. Muralidharan, Head Dept. of SS

3) Dr. A.C. Mathew, Senior Scientist

27

4) Dr. K. Balachandra Hebbar, Head,

Division of PB & PHT

5) Dr. C. Thamban, Principal Scientist

(Agrl Extension)

6) Dr. Murali Gopal, Principal Scientist,

Microbiology

7) Mr. S. Jayasekhar, Scientist (SS)

A.

List of Meetings organized (CIC, CAC, CMU, etc.)

S. No. Details of the meeting

Date

1.

2.

3.

CIC

Meeting is conducted on a Weekly

weekly basis with the PI,

CoPI and other members

CAC

Advisory Board Meeting

25/10/13

CMU

Management Committee

25/10/13

Place & Address (Where meeting

was organized)

CPCRI, Kasaragod

Committee Hall, CPCRI

CPCRI, Kasaragod

28

Part-III: Budget and its Utilization

STATEMENT OF EXPENDITURE (Final)

(Period from 21/5/13to31/3/14)

(Date of start)

(Date of completion)

Sanction Letter No- 30(1)/2013/CPCRI/BPD/NAIP/O&M

Total Sub-project Cost `160.16 LAKHS

Sanctioned/Revised Sub-project cost (if applicable) `_______________

Date of Commencement of Sub-project- 21st MAY

Duration: From 21/5/13to 31/3/14

Funds Received in each year

I Year `128.95 LAKHS

II Year `__________________

III Year ` _________________

Bank Interest received on fund (if any) ` NIL

Total amount received ` 160.16

Total expenditure ` 128.95

Expenditure Head-wise:

Sanctioned Heads

Funds

Funds Released

Expenditure Incurred

Alloca 1st Year 2nd 3rd

1st

2nd

3rd

ted (*)

Ye

ar

Year

Year

Year

Year

Total

Expend

iture

Balance

as on

date

Requirement

of additional

funds

Remarks

A. Recurring

Contingencies

(1) TA

2.50

1.25

(2) Workshops

6.00

3.00

(3) Contractual

19.60

9.80

Services/RA/SRF

(4) Operational

25.00

12.50

expenses

Sub-Total of A (1-4)

53.10

26.55

B. HRD Component

(5) Training

1.50

1.50

(6) Consultancy

4.00

2.00

Sub-Total of B (5-6)

5.50

3.50

C. Non-Recurring

(7) Equipment

55.25

55.25

(8) Furniture

(9) Works (new

40.00

40.00

renovation)

(10) Others (Animals,

1.00

1.00

Books, etc.)

Sub-Total of C (7-10)

96.25

96.25

D. Institutional

5.31

2.65

Charges*

Grand Total

160.16 128.95

8.165

8.165

(A+B+C+D)

** All values are in LAKHS

* Institutional charges will be 10% of the recurring contingencies for the Lead Consortium and 5% for Consortia Partners.

Name & Signature of CPI :

Name & Signature of Competent Financial authority:

Date:__________

Date:__________

Date:_________

Signature, name and designation of Consortia Leader

29

PART-IV: DECLARATION

This is to certify that the final report of the Sub-project has been submitted in full

consultation with the consortium partners in accordance with the approved objectives and

technical programme and the relevant records, note books; materials are available for the same.

Place:_________

Date:_________

Signature of Consortium Principal Investigator

Signature & Date

Consortium Co-Principal Investigator

Signature & Date

Consortium Co-Principal Investigator

Signature & Date

Consortium Co-Principal Investigator

Signature & Date

Consortium Co-Principal Investigator

Comments & Signature of Consortium Leader

Date:

30

Appendix-1

Performance Indicators for Component-1: ICDS

S.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Indicator

Total No.

No. of hits on the sub-project website per month

Number of knowledge products developed:

a. e-courses

b. e-learning modules

Digitization of number of:

a. Ph. D. Theses

b. Historical publications

Enhanced knowledge sharing and public awareness activities carried

out

Development of linkages with

a. National organisations -6

b. International organisations-1

No. of articles downloaded from CeRA subscribed publishers

Training of critical mass (no. of experts trained)

Number of scientists trained overseas in the frontier areas of science

Number of scientists trained overseas in consortium-based subject

areas

No. of scientists participated in conference/seminar etc. abroad

Number of novel tools/protocols/methodologies developed

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

7

1

10,200

31

Performance Indicators for Component-1: BPD

S.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Indicator

No. of technologies commercialised

No. of entrepreneurs incubated/enrolled

No. of incubates graduated

No. of entrepreneurs supported/ trained

Client servicing (commitment/delivered)

Revenue generated for the BPD

Amount of funding mobilized for incubates

No. of consultancy assignments undertaken

Farmers directly benefitted with value addition

No. of local employment generated (direct) through incubates

No. of mergers & acquisitions, joint ventures, tie-ups made

BPD surplus fund (` lakhs)

Total No.

8

2

2

1

36,000

1

2

200

1

a. Number of applications filed for patent

b. Number of patents granted

Number of scientists trained overseas in the frontier areas of science

Number of scientists trained overseas in consortium-based subject

areas

No. of scientists participated in conference/seminar etc. abroad

Number of novel tools/protocols/methodologies developed

1

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

32

Performance Indicators for Component-1: L&CB

S.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Indicator

Number of scientists trained overseas in frontier areas of science

Number of scientists trained overseas in consortium based subject

areas

No. of national trainings involving international resource persons

Number of NARS scientists trained by the overseas trainees after

return

Number of user manuals developed

Number of workshops conducted for capacity building

Number of scientists participated for capacity building workshops

No. of scientists participated in conference/seminar etc. abroad

Increase in number of linkages formed with KVKs and

Communication Information Centres (CICs)

Number of novel tools/protocols/methodologies developed

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Total No.

3

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

33

Performance Indicators for Component-1: PGAV

S.

No.

Indicator

Total No.

Annual no. of visioning & policy analysis/ market intelligence/

1. technology forecasting events organized through or in association

with NAIP

Annual no. of people attending visioning & policy analysis, market

2. intelligence and /or technology forecasting events organized and

attended through or in association with NAIP

3. Revenue received from carbon trading

Increase in number of responded queries from public and private

4.

organizations, NGOs per month

5. Number of scientists trained overseas in the frontier areas of science

Number of scientists trained overseas in consortium-based subject

6.

areas

7. No. of scientists participated in conference/seminar etc. abroad

8. Number of novel tools/protocols/methodologies developed

9. Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

34

Performance Indicators for Component-1: RFPS

S.

No.

1.

2.

3.

4.

5.

6.

7.

Indicator

Total No.

Number of weeks for the procurement cycle of high threshold

goods

Number of ICAR institutes where FMS/MIS implemented

Number of personnel trained overseas in the frontier areas of

science

Number of personnel trained overseas in consortium-based subject

areas

No. of scientists participated in conference/seminar etc. abroad

Number of novel tools/protocols/methodologies developed for

RFPS

Publications if any

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

35

Performance Indicators for Component- 2

S.

Indicator

No.

21. No. of production technologies released and/or adopted

22. No. of processing technologies released and/or adopted

Number of technologies/products commercialized based on NAIP

23.

research

24. No. of new rural industries/entreprises established/ upgraded

25. No. of product groups for which quality grades developed and agreed

Total no. of private sector organizations (including NGOs) participating

26.

in consortium

27. No. of farmers involved in consortia activities

28. Total number of farmers’ group developed for marketing and processing

Number of patent/intellectual property protection applications filed based

29.

on NAIP research

Number of patents/intellectual property protections granted/published

30.

based on NAIP research

31. Number of scientists trained overseas in the frontier areas of science

32. Number of scientists trained overseas in consortium-based subject areas

33. No. of scientists participated in conference/seminar etc. abroad

34. Success stories

35.

Incremental employment generated (person days/year/HH)

36.

Increase in income of participating households (` per annum)

37.

38.

Number of novel tools/protocols/methodologies developed

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

Total No.

Baseline Final

Baseline Final

36

Performance Indicators for Component-3

S.

No.

Indicator

Total No.

6.

Number of new technologies developed and introduced in the project

area

Number of improved technologies introduced in project areas

Number of improved technologies adopted in these areas

Number of farmers involved in consortia activities

Increase in agriculture services and processing enterprises in project Baseline Final

area

Baseline Final

Increase in income of participating household (Rs/Annum)

7.

Number of farmer groups involved in consortia activities

8.

Incremental employment generated (person days/year/HH)

9.

No. of farmers/area in addtion to project beneficiary farmers adopting

introduced technologies

1.

2.

3.

4.

5.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Baseline Final

Farmers

(No.)

Area

(ha)

Number of patent/intellectual property protection applications filed

based on NAIP research

Number of patents/intellectual property protections granted/published

based on NAIP research

Number of scientists trained overseas in the frontier areas of science

Number of scientists trained overseas in consortium-based subject

areas

No. of scientists participated in conference/seminar etc. abroad

Success stories

Amount of sustainability fund corpus created (` Lakh)

Number of novel tools/protocols/methodologies developed

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

37

Performance Indicators for Component-4

S.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Indicator

Total No.

Number of new technologies released and/or adopted based on NAIP

research

Number of technologies commercialized based on NAIP research

No. of novel tools/ protocols/ methodologies developed

No. of patents/other IPRs based on NAIP funded research

a) Number of molecular resources augmented/ submitted to GenBank

b) Patent applications filed

c) Patent granted

d) Application for other IPR filed

e) Other IPR granted

No. of Registrations of products/reference materials made (w.r.t.

standards for commerce or academic reference, etc. e.g. for

Biopesticides/other

standards,

depository

for

Taxonomic

Classification, elite germplasm registration, etc.)

Number of scientists trained overseas in the frontier areas of science

Number of scientists trained overseas in consortium-based subject

areas

No. of scientists participated in conference/seminar etc. abroad

Publications

Articles in NAAS rated journals

Articles in other journals

Book(s)

Book chapter(s)

Thesis

Popular article(s) (English)

Newspaper article(s)

Seminar/Symposium/Conference/Workshop Proceedings

Technical bulletin(s)

Manual(s)

CDs/Videos

Popular article(s) in other language

Folder/Leaflet/Handout

Report(s)

Success stories

38

General Instructions and Guidelines

1)

2)

3)

4)

5)

6)

7)

The CPI will send the consolidated report to PIU-NAIP after compiling the progress reports

received from all the consortium partners. The report should also list the constraints (if any)

being faced by consortia partners.

The Final Report should not be a mere repetition of Annual Reports. The purpose of the

final report is to link all findings from the sub-project so that the overall achievements are

discussed in terms of scientific accomplishments, contributions to scientific, human capital

development, the relevance of findings to development, and how the information

technology is to be disseminated.

The Executive Summary should review and summarize the entire Sub-project. The

Executive Summary should clearly place sub-project accomplishments in the overall

context of agricultural development.

Summary in Hindi must be included.

Final Report should be of A-4 size and the total number of pages must not exceed 50-60 in

any case.

The text of the Final Report should be in the following format:

MS Word document

Line spacing: 1.15

Font: Times New Roman

Main headings: 12 point bold

Running text: 12 point normal

Following colour schemes to be used for cover page (front & back) by sub-projects under

different components

Component-1:

Light Orange

#F79646

Component-2:

Light Pink

Component-3:

Light Green

Component-4:

Light Blue

#FF99CC

#33CC33

#66CCFF

8)

Ten hard bound printed copies of Final Report should be submitted. Also, soft copy of the

Final Report in MS Word document (2003) should be sent in the CD in duplicate.

9) The details of performance indicators claimed in the listing should be submitted as soft

copy in CD in MS Word Format. A copy of each publication, film, knowledge products,

patent application to be attached in a separate folder.

10) CPIs must strictly follow the guidelines while composing and printing the sub-project Final

Report.

11) The draft of Final Report in soft copy be sent 15 days before sub-project closing date to

concerned National Coordinator. Final printing be done after getting comments/suggestions

on draft report.

39

40