to presentation ()

Approved system Integrator

• Operator display system

• DCS and PLC controllers

• AC/DC Drives

•

LV control

• Weighing systems

Trading since 1983

Standards:

Member of British Standards

Quality Assured to ISO9001

Employee Training Provider

-Health & Safety Passports

-Continued Technical training

-CSCS Accredited training

DCS Programming &

Configuration

Operator display construction

Level 2 communication

Electrical design

Control Loop

Logic control

AC/DC drives

Field bus engineering

Installation Design

-Layouts, Cabling, containment

Site services

CUSTOMER REFERENCES:

•

ABB UK & ABB SWEDEN

•

CORUS all main sites

•

OTTOKUMPO

•

CAPARO

• CO-STEEL SHEERNESS

• GEORGIA PACIFIC

• SHEFFIELD FORGEMASTERS

•

NORTHERN LIGHTHOUSE

BOARD

•

MERSEY DOCKS AND

HARBOUR

COMPANY

• IPSENS BIOPHARM

• KCCL OF UGANDA

• SWEDISH NATIONAL

PROPERTY BOARD

•

MANCHESTER SHIP

CANAL COMPANY

• SCOTTISH NUCLEAR

• CEREAL PARTNERS

• BRITISH ENERGY

•

EPR GLANFORD

• PHARMAGRAPH

• ACQUISITION SYSTEMS

• NATIONAL BLOOD SERVICE

• DAVID BROWN TEXTRON

SYSTEM ENGINEERING

• Ship unloading

• Materials handling

• Blast Furnace

• BOS Plant

• Concast

• Rolling Mill

• Power Station

•

Light house

• AC/DC Drives

• Machine Automation

• Weighing Systems

CONTROL PANEL &

DESK MANUFACTURE

• Electrical design Service

• MCC Suites

• Controller and PLC Cubicles

• Remote I/O Cubicles

•

Drive Panels

• Instrument Panels

• Desks and Consoles

• Pneumatic Controls

SITE SERVICES

• Ship unloader control upgrading

• Crane control upgrading

• DC Drive rebuilds

• AC Drive replacements

• Environmental monitoring installation

• Control system & Drive maintenance

•

Electrical Installations

• Site Inspection & Testing

• Portable appliance testing

ELECTRONIC ENGINEERING

REPAIR OF FOLLOWING EQUIPMENT:

• Industrial PC’s

•

DCS & PLC units

•

Processor cards

•

Memory cards

•

Communication cards

•

Power supplies

•

Drives & Drive modules

•

Weighing systems

•

Instrument processing

•

Controllers

ELECTRONIC

ENGINEERING

DIAGNOSTIC TOOLS:

•

Clip over back driving component testing machines

• VI signature analysis machines

• Passive components measuring instrument

• Network and field bus analysis equipment

• High accuracy test equipment

TESTING STATIONS

-ADVANT 400; S100 I/O; S800I/O; S400I/O

-MP200/1; MP200; MP100W; MP100

-MV820; MV830/1; MV850; MV850/1

-TYRAK MIDI; DCS 500; DCS600; BBC

-AC800M

OTHER

-GEM80; SQUARE D; ALLEN BRADLEY

-ROCHESTER INSTRUMENTS; IMO

DRIVES

ELECTRONIC ENGINEERING

UPGRADING/ REPLACEMENT

SERVICE

ADVICE SUPPORT AND SITE

SERVICE TO

UPGRADE/REPLACE

• Controllers

•

Operator process panel

•

AC drives

• DC drives

•

Weighing systems/modules

•

Display systems

• Network components

•

Engineering stations

•

Power supplies

ELECTRONIC ENGINEERING

Design and build of electronic product

• Wide spectrum LED LUMINAIRE

• Keyboard solutions

• Obsolete product replacement

In Alliance with

Crane

Division sweden

SHIP UNLOADING AND

CRANE CONTROL

• Power network distribution

• LV distribution

• AC/DC Drive control

- Body; Trolley: Hoist; Grab;

Gantry; Conveyor

• Crane view system

•

Crane maintenance system

• Camera display system

• Crane controllers

•

Weighing

• Retrofits a speciality

MATERIALS HANDLING

• Operator screen construction

• Object design of material routes

• Sequence control of process

• Object control of material reception

• RFID TAG identification

BLAST FURNACE

CONTROL

• System topology design

• Electrical / Instrument Design

•

Operator screen construction

• Controller programming

• Furnace top / Stock house weighing

• In haul of materials

• Installation / Commissioning

•

Swap over on down days

BOS PLANT (BASIC

OXYGEN STEELMAKING)

• Converter weighing system

• Ladle weighing system

•

Level 2 communication

• Operator interface

• Material object design

• Production reporting

• Maintenance and calibration facilities

CONCAST ENGINEERING

• Slab weighing

• Ladle weighing

• Tundish weighing

• Tundish level control

• Radio telemetry system

• Communication to level 2

• Maintenance

ROLLING MILL CONTROL

• Operator screen construction

•

Programming and configurations of controllers

• Level 2 Linking TCP/ IP

• IBA Logging connection using TCP/IP

• PROFIBUS Integration

•

REMOTE I/O

• FIELDBUS linking to drives

• Schedule modifications

• Stand Assembly / Disassembly control

• Technical training

POWER STATION CONTROL

• Raw materials handling

• ID fan drive

• Boiler control

• Interfacing to generator

• MV/HV metering

• Radio Telemetry

• Penstock control

•

Synchronising relay interfacing

• Transformer interfacing

• Switching control

LIGHTHOUSE AUTOMATION

• Solar- Battery regulation

• Optic- Lamp Driver Control

• Optical control-Normal / Emergency

• Optical Monitoring System

• Pedestal Rotation-Monitoring

System

• Bouy Monitoring

•

Battery Housings & Distribution

AC/DC DRIVES

• DC Rebuilds retaining power components

• DC Rebuilds using modules

• DC Drive design/build/install/commission

• DC/AC Field bus interfacing to controllers

• AC MV Drives

• AC 690V Drive systems

•

AC Multidrives

• AC Drives general

• Drives Maintenance

MACHINE AUTOMATION

• Scaleable Solutions

• Operator Interfaces

-Process Panels/ Operator displays

• Safety Evaluation

• Controller programming in five languages

• Field bus solution to minimise installation wiring

•

SIL rated controllers

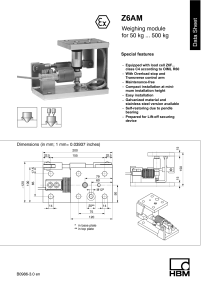

WEIGHING SYSTEMS

Engineering of system for such applications as:-

•

HOPPER

•

RAIL (Loco, Torpedo cars)

• SLAB

• TUNDISH

• SILO

•

CRANE

• STOCKHOUSE

• FURNACE TOP

• LADLES

• RADIO TELEMETRY LINKS