7. - General Plan

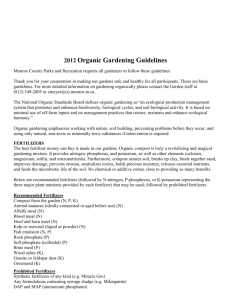

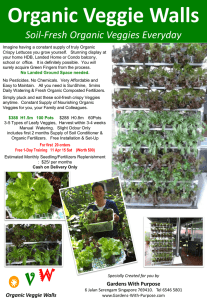

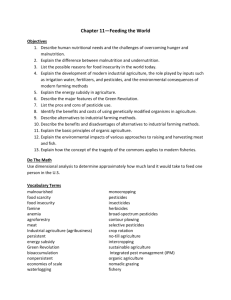

advertisement