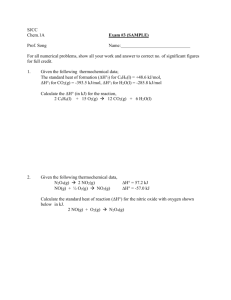

troubleshooting amine plants using mass transfer rate

advertisement

Simulation of Amine Plants: Fundamental Models and Limitations 2das Jornadas Técnicas Sobre Acondicionamiento del Gas Natural 30 de Septiembre al 3 de Octubre de 2008 El Calafate, Argentina Jenny Seagraves INEOS Oxide GAS/SPEC Technology Group IAPG 2008 Topics of Presentation General history and overview of fundamental models refer to paper and references in papers for more details Case Studies Important considerations or ideas for designing or optimizing an amine plant IAPG 2008 History and Fundamentals of Amine Simulation Models IAPG 2008 Improved simulation model are developed as solvent technologies evolve and amine plant become more complex…. TEA 1930 MEA DEA 1940 DGA 1950 MDEA Simple Models (Hand Calculations) IAPG 2008 Specialty Amine 1960 1970 1980 & Beyond…. DIPA Complex Computer Models Simulation of MDEA and newer specialty solvents... MDEA-based and specialty solvents more difficult to simulate contain MDEA and sometimes blends of chemicals that yield specific treating characteristics have components with different reaction kinetics MDEA solvent have different temperature profile than MEA or DEA. Simplified computer calculations are dangerously misleading for MDEA and specialty amine designs IAPG 2008 Improved Simulation is Needed as Amine Plant Designs Evolve... While 20 trays absorber & regenerator designs are still most common …. We now are designing amine plants with multiple feeds and side draws Complex multi-staged flash to reduce energy New mass transfer devices to get more capacity » new packing material or trays » or a combination of the two. IAPG 2008 Example of Amine Plant with Multi-feeds and Flash CO2 Lean Amine T = 130 F (50 C) Absorber Semi-lean Regenerator Syngas IAPG 2008 Rich Amine Reboiler Definitions Vapor Liquid Equilibrium (VLE) Defines the solution chemistry / chemical species present model determines the maximum limit of H2S and CO2 absorbed Reaction Rates Defines how quickly H2S and CO2 are absorbed H2S react instantaneously with amines and CO2 react at various rates depending on type of amine. Mass Transfer Rate Define the surface area and how quickly the surface area is refreshed for H2S and CO2 absorption IAPG 2008 Vapor Liquid Equilibrium IAPG 2008 ionization of water 2 H2O H3O+ + OH- (eq. 1) dissociation of hydrogen sulfide H2O + H2S H3O+ + HS- (eq. 2) dissociation of bisulfide H2O + HS- H3O+ + S2- (eq. 3) dissociation of carbon dioxide 2 H2O + CO2 H3O+ + HCO3- (eq. 4) dissociation of bicarbonate H2O + HCO3- H3O+ + CO32- (eq. 5) dissociation of protonated alkanolamine H2O + RR’R’’NH+ H3O+ + R’R’R’’N (eq. 6) carbamate reversion to bicarbonate RR’NCOO- + H2O RR’NH + HCO3- (eq. 7) Vapor Liquid Equilibrium The equations governing chemical equilibria for equations 1 to 7 may be written as: K = i (xi i )i (eq. 8) where, K is the equilibrium constant xi is the mole fraction of species i i is the activity coefficient of species i i is the stoichiometric coefficient IAPG 2008 Chemical Kinetics and Mass Transfer Ni = Ei k°i,L a (yi interface - yi Bulk) (eq 8) NI = transfer rate Ei = enhancement factor (accounts for chemical reaction) k°i,L = Mass transfer coefficient a = interfacial area yi interface= acid gas conc. at interface (from Henry’s law) yi bulk = acid gas conc. in bulk (from VLE) IAPG 2008 Evolution of Amine Simulation Pre 1980s - Equilibrium Stage Approach was only method Uses simplified estimates More rigorous Estimate chemical species in solution Calculate exact chemical species present in solution Uses tray efficiencies lump reaction and mass transfer rates Calculate reaction and mass transfer rates Adequate for simulation of MEA and DEA Accurate for MEA, DEA, MDEA, and Specialty amine solvents Not accurate for MDEA, specialty solvents, and complex amine mixtures Still used in many commercial simulators today IAPG 2008 After 1980s - Mass Transfer Rate Based Approach Can be extended to systems with heat stable salts and other components if data is available Used in only a few simulators History of Mass Transfer Rate Based Simulation Approach Idea to combine mass transfer with chemical reactions in amine simulation came about as a result of works by Astarita, Weiland, Katti, and others. In early 1980s, GAS/SPEC funded a series of research projects to developed the first amine simulator that combined rigorous vapor-liquid-equilibrium (VLE) modeling with mass transfer and chemical reactions calculations Mass Transfer Rate-based simulation has been used and refined over the last 20+ years by the GAS/SPEC group Available in certain simulators such as GAS/SPEC APS Simulator (proprietary simulation program) IAPG 2008 Commercially available ProTreat Simulator (Optimized Gas Treating Inc.) What is mass transfer rate-based? IAPG 2008 Example of GAS/SPEC APS Simulation IAPG 2008 Most Basic Amine Simulation Models Use tray efficiencies to account for •mass transfer •reaction rates Tray Efficiency Properties Simulation Efficiencies are empirically derived Ignore tower internals •use equivalent stages to represent a given number of trays or packing height IAPG 2008 Material Balance Phase Equilibrium Predicted Plant Performance Mass Transfer Rate-based Simulations More detailed approach Avoid the use of efficiencies Considers differences in reaction rates of H2S and CO2 Consider Mass Transfer rate of absorption in different tower internals (trays, packing, etc.) IAPG 2008 Mass Transfer (Tower internals) Reaction Kinetics Properties Simulation Material Balance Phase Equilibrium Predicted Plant Performance Advantages of MT Rate-based Models Makes more rigorous and accurate prediction inside column Example of Actual vs Predicted 21 temperature profile identify trouble area in the column » equilibrium limits » areas of corrosion concerns due to high temperatures 17 Tray Number reaction or absorption zone ProTreat Actual 19 15 13 11 9 7 5 3 1 100 110 120 130 140 Temperature (F) IAPG 2008 150 Equilibrium Stage Approach No one-to-one correspondence of theoretical stage with position in column 3 trays per stage ? Or 4 trays per stage?…etc. Top Tray Stage 3 Difficult to locate exact temperature and composition of feeds and side draws Tray location? Stage 2 Stage 1 Feed IAPG 2008 Tray location? Temp? Composition? M.T. Rate-based Approach Know temperature and composition on every actual tray Can accurately locate optimum points for feeds and side draws Top Tray Tray is known Tray is known Temp is known Feed IAPG 2008 Case Studies IAPG 2008 Case Study 1 High pressure coal bed methane gas requires CO2 removal only plant have ability to treat a portion of the natural gas and blend to meet 3 mol% CO2 spec IAPG 2008 Case 1 - Flow Diagram TREATED GAS REFLUX CONDENSER LEAN AMINE REFLUX ACCUMULATOR REGEN ABSORBER FILTER TRAIN FEED AMINE COOLER REBOILER RICH AMINE LEAN /RICH CROSS-EXCHANGER IAPG 2008 Benchmark Performance Tests Test 1 Test 2 Test 3 Raw Gas Flow (Nm3/h) Temperature (oC) Pressure (kPa) CO2 (mol%) 235500 40 6881 4.29 232100 40 6881 4.29 200900 40 6881 4.21 Lean Solvent Flow (m3/h) Temp (oC) Wt% MDEA 227 40 48 186 43 48 227 39 48 IAPG 2008 Performance Compared to Simulation Solvent Rate (m3/h) Gas Rate (Nm3/h) Treated Gas Measured CO2 (mol%) Predicted CO2 (mol%) Lean Amine Actual mol/mol Predicted mol/mol Rich Amine Predicted mol/mol IAPG 2008 Test 1 227 235500 Test 2 186 232100 Test 3 227 200900 1.54 1.57 1.98 1.95 1.20 1.20 0.008 0.0075 0.008 0.0059 0.007 0.0046 0.310 0.403 0.294 Performance Compared to Simulation Solvent Rate (m3/h) Gas Rate (Nm3/h) Treated Gas Measured CO2 (mol%) Predicted CO2 (mol%) Lean Amine Actual mol/mol Predicted mol/mol Rich Amine Predicted mol/mol IAPG 2008 Test 1 227 235500 Test 2 186 232100 Test 3 227 200900 1.54 1.57 1.98 1.95 1.20 1.20 0.008 0.0075 0.008 0.0059 0.007 0.0046 0.310 0.403 0.294 Actual versus Simulation Predicted Temperature Test 2 - Absorber Test 3 - Absorber 21 21 21 19 19 19 17 17 17 15 15 15 Tray Number 13 13 11 13 Tray Number Tray Number Test 1 - Absorber 11 9 7 9 7 11 9 7 5 5 3 3 3 1 38 1 38 1 38 49 60 71 Temperature (°C) 49 60 71 Temperature (°C) Actual temperature measurements Simulated Temperatures IAPG 2008 82 5 49 60 Temperature (°C) Significance of Temperature Profile Concern with Temperature Profile because higher and broader profile have corrosion implications outlet gas temperature increase load on downstream dehydration equipment high temperature may limit capacity or cause plant to go off spec difficult to absorb CO2 » near equilibrium loading IAPG 2008 Tower Temperature Profiles Broad temperature profile throughout Poor liquid distribution GAS/SPEC technical service engineers use these temperature scans of towers to troubleshoot amine plant. This is a method to monitor performance IAPG 2008 Options for More Capacity Customer wants more capacity out of the plant However CO2 level in inlet gas is rising! Option 1 - Continue to treat with MDEA Treat to just below 3% CO2 specification Option 2 - Upgrade to a Specialty Solvent Treat CO2 to low levels of < 1000 ppm then blend with untreated gas to meet 3% CO2 specification IAPG 2008 Max Capacity with MDEA 600000 Pipeline Max Treated Gas Flow, Nm3/h 500000 Bypassed Combined 400000 300000 200000 100000 0 3.5 4 4.5 5 Inlet CO2, mol% IAPG 2008 5.5 6 6.5 Max Capacity with Specialty Solvent Gas Flo w, Nm3/h 900000 800000 Treated 700000 Bypassed Pipeline Max 600000 Combined 500000 400000 300000 200000 100000 0 3.5 4 4.5 5 Inle t CO2, mol% IAPG 2008 5.5 6 6.5 Results after Conversion Flow to Absorber (Nm3/h) Inlet CO2, mol% Outlet CO2, mol% Amine Flow, Nm3/h MDEA 235500 4.29 1.54 227 CS-2010 232100 4.5 < 0.1 202 Max Total Gas Capacity (Nm3/h) 446400 502200 Currently IAPG 2008 limited by capacity of downstream pipeline Conclusions - Case 1 Demonstrates use of simulation tool to accurately predict temperature and CO2 in the column. identify opportunities for optimization of existing plant make decision on how to best utilize assets for present and future treating conditions IAPG 2008 Case Study 2 Offshore natural gas application H2S and CO2 removal Simulations used to design original plant modify plant to adapt to changing process conditions IAPG 2008 Case 2 - Flow Diagram TREATED GAS REFLUX CONDENSER LEAN AMINE REFLUX ACCUMULATOR REGEN ABSORBER FILTER TRAIN FEED AMINE COOLER REBOILER RICH AMINE LEAN /RICH CROSS-EXCHANGER IAPG 2008 Original Design Treating Conditions IAPG 2008 Inlet Gas Flow (Nm3/h) Inlet Gas Pressure (kPa) Inlet Gas Temp (°C) 502200 7419 49 Gas Composition: CO2 (mol%) H2S (mol%) 3.25 1.35 Treated Gas Specification: CO2 (mol%) H2S (ppmv) <1 <4 Key Design Decisions Prior to INEOS involvement, customer decided on 30 tray absorber (3.35 meters diameter with 10 cm weir height) design based on generic MDEA plant was already designed with “Equilibrium Stage”-based simulator Use of 30 trays is unusual in an offshore application due to weight consideration IAPG 2008 Simulation - Design Rate Gas Flow (Nm3/h) Feed Tray from Top MDEA Conc. (wt% ) Circulation Rate (m3/h) 502200 30 50% 545 Treated Gas CO2 (mol%) H2S (ppmv) 0.92 < 1 ppm Lean Loadings / Rich Loadings H2S (mol/mol) 0.0002 / 0.13 CO2 (mol/mol) 0.005 / 0.23 IAPG 2008 Variations operating conditions were also simulated... IAPG 2008 Simulations for Changing Condition Limited heat source at certain times 57% of design duty available Plant will operate at reduced rate Increased CO2 pickup at reduced rate How to operate plant to minimize CO2 pickup IAPG 2008 Alternatives for Operating at Reduced Rates Scenario 1 502200 Nm3/h Reboiler Duty = X 30 trays CO2 Out = 0.92 mol% Scenario 2 IAPG 2008 30 trays 279000 Nm3/h 340 m3/h of 50wt% MDEA Reboiler Duty = 0.57 X CO2 Out = 0.59 mol% 19 trays 279000 Nm3/h 340 m3/h of 50 wt% MDEA Reboiler Duty = 0.57X CO2 Out = 0.99 mol% Outcome of Simulations Feed points added to trays 30, 24, 19 to allow for flexibility under changing conditions Tray 30 ABSORBER Tray 24 Tray 19 Feed IAPG 2008 Prior to Startup Plant needed lower CO2 level Minimize corrosion in downstream pipeline Old spec 1% CO2 ; New spec 1000 ppmv CO2 In order to maximize CO2 removal, customer has 2 options Option 1 - Continue with MDEA » Higher amine circulation rate, L/V » Use all 30 trays Option 2 - Specialty amine solvent » Treat with less trays and less circulation Customer decide to proceed startup with MDEA and then upgrade to a specialty solvent. IAPG 2008 After Startup After startup, the plant experienced foaming Plant had difficulty treating at high capacity Not making the 1% CO2 spec with MDEA Problem was caused by Hydrocarbon coming into the plant High amine flow and high tray count required by MDEA seem to worsen foaming problem » operate with only 19 trays » over-circulate to keep the CO2 level down IAPG 2008 Conversion to Specialty Solvent After operating with MDEA for 5 months, customer converted to GAS/SPEC* CS-2000 solvent Running conversion. Now plant treating at full capacity of 450 MMSCFD Meeting < 1000 ppmv CO2 spec Only the bottom 19 trays were needed Reduction in foaming tendency » better separation / filtration » higher loading decrease HC solubility IAPG 2008 Conclusions - Case 2 Ideally want to design a plant with fewer trays and higher rich loadings to reduce capital cost to minimize hydrocarbon absorption Simulation used to determined alternative feed points to improve plant flexibility Simulations helped adapt plant to new treating requirements with a specialty solvent IAPG 2008 Case Study 3 Natural gas plant plant faced with rising CO2 composition Originally 7.8 mol% CO2 is now over 10% Plant operation was unstable because high outlet CO2 caused coldbox to freeze Goal is to increase capacity and stabilize plant operations IAPG 2008 Operating Conditions versus Simulated Flow (Nm3/h) Temperature (°C) Pressure (kPa) Inlet CO2 (mol%) Actual CO2 Out (ppm) Predicted CO2 Out (ppm) IAPG 2008 34600 11 4440 10.2 10 10 Lean Solvent Flow (m3/h) Temperature (°C) Wt% GAS/SPEC CS-2020 82 48 50 Rich Solvent Temperature (°C) Predicted Temp (°C) 79 to 81 81 Operating Conditions versus Simulated Flow (Nm3/h) Temperature (°C) Pressure (kPa) Inlet CO2 (mol%) Actual CO2 Out (ppm) Predicted CO2 Out (ppm) IAPG 2008 34600 11 4440 10.2 10 10 Lean Solvent Flow (m3/h) Temperature (°C) Wt% GAS/SPEC CS-2020 82 48 50 Rich Solvent Temperature (°C) Predicted Temp (°C) 79 to 81 81 Effect of Rate on CO2 Concentration CO2 in Vapor, ppmv 1 10 100 1 3 5 Tray # (Top down) 7 9 11 13 15 17 19 21 23 IAPG 2008 36800 Nm3/h 35700 Nm3/h 34600 Nm3/h 1000 10000 100000 Effect of Rate on CO2 Loadings Loading, mol/mol 0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 1 3 36800 Nm3/h 5 35700 Nm3/h Tray # (Top down) 7 34600 Nm3/h 9 11 13 15 17 19 21 23 IAPG 2008 Little CO2 absorption Effect of Rate on Column Temperature Temperature, °F 120 1 Tray # (Top down) 140 150 160 170 180 190 200 36800 Nm3/h 3 35700 Nm3/h 5 34600 Nm3/h 7 9 11 13 15 17 19 21 23 IAPG 2008 130 210 Outcome - Case 3 Plant personnel confirmed maximum rate of 34600 Nm3/h Client considering upgrading pumps and exchangers in order to increase/maintain capacity as inlet CO2 rises IAPG 2008 Conclusions - Case 3 MT Rate based simulation gave insight on effect of gas rate on treat and temperature profile Allows plant to make informed decisions for future IAPG 2008 Conclusions Discussed the advantages of Mass Transfer Rate Based Simulation over other simulation methods Case studies have shown accuracy of column temperature/composition prediction effect of mass transfer (tray count) on performance how to use simulator to design/modify in changing conditions the importance in considering temperature effects IAPG 2008 Acknowledgement Ulises Cruz - INEOS Andy Sargent - INEOS Ralph Weiland - Optimized Gas Treating, Inc. * GAS/SPEC and CS-2000 are trademarks of INEOS Oxide TM ProTreat is a trademark of Optimized Gas Treating, Inc. IAPG 2008 QUESTIONS? IAPG 2008