WS3 Gauglitz_ECRN_Ludwigshafen Nov_2007Gauglitz

advertisement

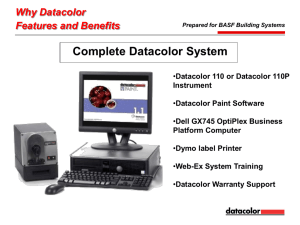

Success – BASF‘s Approach to Sustainability in Customer Interaction European Chemical Regions Network (ECRN) 29./30.11.07 Ludwigshafen Dr. Uwe Gauglitz The Four Strategic BASF Guidelines for Long-term Success Earn a premium on our cost of capital Form the best team in the industry Help our customers to be more successful Ensure sustainable development Responsible Care®: Part of Corporate Goals BASF assumes responsibility for safety, health and environment beyond what is required by legal regulations. The company asserts its claim to maintain and help shape the political background conditions that secure competitiveness. As the world’s leading chemical company, BASF sees itself as having a special responsibility to implement international strategies and standards within its own company. BASF`s environmental balance reflects the success of intelligent energy and waste disposal concepts that reduce CO2 emissions and conserve resources. One of the key challenges of Responsible Care® is… …the promotion of RC goals within the whole value chain Success – Adding Value through Sustainability Success bundles BASF‘s Responsible Care® expertise in the fields of sustainability management, health, safety, and environment. This expertise is based on decades of own strategic and operational experience, as well as more than 350 projects with customers and suppliers. Together with our products, we offer that expertise to our customers and suppliers. The goal of Success We want to… increase and spread sustainable development beyond our internal activities. help our customers to be more successful. create enduring customer partnerships by working together for sustainable development. Provide an additional differentiation factor and new market opportunities … create business value for both parties: a winwin situation Success Service areas PROCESS: “We assist you in optimizing your processes” Waste Management Wastewater Treatment Energy Consultancy Health and Safety at the Workplace Emergency Response PRODUCT: “We analyze your product potential“ Environmental trace analysis REACH Consultancy Hazardous Substance Management Toxicology and Ecology The Eco-Efficiency Label STRATEGY: “We support your strategies“ Sustainability Management Eco-Efficiency Analysis Energy Efficiency Climate Protection Examples of customer partnership projects Eco-efficient milk packaging Environmentally friendly wastewater treatment Reduction of odour nuisance Need Need Need A client from the automotive industry introduced a new coating process which caused an additional 150.000 liters of wastewater per day. A dairy producer is looking for the most ecological and profitable milk packaging solution. An Italian customer was faced with massive complaints from neighbours and the authorities about an odour nuisance arising from his plant. Our Contribution Our Contribution Our Contribution The BASF wastewater experts developed a system to solve the problem - as a result the automobile manufacturer could switch to the new coating process as scheduled. BASF‘s eco-efficiency analysis contributed to the political decision to exclude certain plastic containers from the deposit system. With BASF’s support technical and organizational improvements could be identified and implemented. The odour was eliminated and good relations with neighbours and authorities were restored. Conclusions Potential for further Success More than 350 projects since the beginning of the Initiative Broader customer interaction We spend more time with our customers and suppliers with a non product price related topic… better understanding of our customers and suppliers Promotion of Responsible Care® Strive the promotion of Responsible Care® through the value chain and translate it into business opportunities Contact information BASF Aktiengesellschaft Success-Info-Point D - 67056 Ludwigshafen Telephone: +49 621 60 79777 Fax: +49 621 60 6679777 Email: success-team@basf.com Web: http://www.basf.de/reach What are the main service areas within Success? Product Safety/ Chemical Policy, REACH Experimental Toxicology and Ecology Emissions, Ambient Air Concentrations, Environmental Analysis Waste Management Soil Protection and Ground Water Pollution Wastewater Energy Generation, Energy Conservation Emergency Response Distribution Safety Authorizations, Statutory Regulations Safety, Health at the Workplace Sustainability The REACH Approach REACH The new EU chemicals regulation for the Registration, Evaluation and Authorisation of Chemicals (REACH) came into force on June 1st 2007 REACH applies to all companies manufacturing, importing or using chemicals. The REACH System Objective: Used substances >= 1 t/a Registration of all existing substances on the market 1 t/a (approx. 30.000) within 11 years Registration • Technical dossier • for 10 t/a: Chemical Safety Reports Evaluation Known substances Authorisation Evaluation of the data by the central agency and national authorities Authorisation for special uses of CMR 1+2*, PBT*, vPvB* and other substances “of similar concern” (e. g. endocrine disruptors)* *CMR: carcinogenic, mutagenic, reprotoxic *PBT: persistent, bioaccumulative, toxic *vPvB: very persistent, very bioaccumulative *endocrine disruptors: influencing the hormonal system Timelines of REACH 1 June 200830 Nov 2008 Registr. Pre-registration Entry into force Evaluation Registration >/= 100 t/a Registration 1000 t/a, CMR 1+2 ( 1 t/a), R50-53 ( 100 t/a) End of „Phase-in“ Evaluation Registration Registration >/= 1 t/a Eval. Authorisation / Restriction 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 REACH services for customers as: manufacturers or importers If the customer is a manufacturer or importer of chemicals within the EU, all substances must first be preregistered, then registered. Applications of certain substances require authorisation. Information Assessment of current situation Examination of available documents e. g. Preregistration safety data sheets Registration Testing Authorisation Assessment Drawing up of the chemical safety report Drawing up of authorisation documents Implementation of a socio-economic analysis REACH services for customers as: downstream users As a downstream user of chemicals in the EU, it is usually sufficient to verify whether your use is covered in the extended safety data sheet. You must also adhere to the risk reduction measures described there (e. g. protective equipment, local exhaust ventilation) Assessment of current situation The downstream user decides whether he …. informs his supplier for assessing the use and including it in the safety data sheet; Communication with supplier and training if necessary Assistance for the supplier with fulfilling his REACH obligations or …. would like the use to be assessed independently of the supplier; Assessment of uses Support when communicating with authorities The Success - Team Dr. Uwe Gauglitz Head of Success Services Dr. Andreas Kicherer Success Team Leader Dr. Ana Alba Pérez Dr. Susanne Demharter Management Success Services Marketing REACH Services Monika Schreiber-Dünges Management Success Services Annette Kunde Head of Business Model Development (BMD) Eva Kratzer Business Model Develop. Peter Kölsch Marketing REACH Services Anne Haunhorst Business Model Develop. Tanja Dreyer Success-Info-Point Success provides BASF‘s EHS experts for external customers Business Unit A Success-team customer Administration, offer Business Unit B service Service Production site 2 Production site 1 Experts Experts Experts Coordination Experts EHS-Functional Unit