Statistical Process Control

advertisement

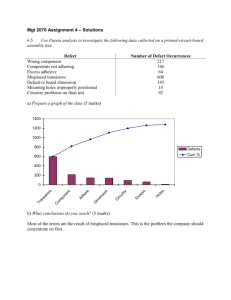

Quality Control Statistical Process Control (SPC) www.ePowerPoint.com www.ePowerPoint.com Step 5 – Control Statistical Process Control (SPC) Use data from the actual process Estimate distributions Look at capability - is good quality possible Statistically monitor the process over time www.ePowerPoint.com Quality Two types of variation www.ePowerPoint.com Two Types of Variation Common Cause Variation (low level) Common Cause Variation (high level) Assignable Cause Variation • Need to measure and reduce common cause variation • Identify assignable cause variation as soon as possible • What is common cause variation for one person might be www.ePowerPoint.com assignable cause to the other Detect Abnormal Variation in the Process: Identifying Assignable Causes Process Parameter Upper Control Limit (UCL) • Track process parameter over time - average weight of 5 bags - control limits - different from specification limits Center Line Lower Control Limit (LCL) Time www.ePowerPoint.com • Distinguish between - common cause variation (within control limits) - assignable cause variation (outside control limits) Statistical Process Control Capability Analysis Eliminate Assignable Cause Conformance Analysis Investigate for Assignable Cause Capability analysis • What is the currently "inherent" capability of my process when it is "in control"? Conformance analysis • SPC charts identify when control has likely been lost and assignable cause variation has occurred Investigate for assignable cause • Find “Root Cause(s)” of Potential Loss of Statistical Control Eliminate or replicate assignable cause www.ePowerPoint.com • Need Corrective Action To Move Forward Statistical process control (SPC) involves testing a random sample of output from a process to determine whether the process is producing items within a preselected range. www.ePowerPoint.com Statistical Process Normal Behavior Control (SPC) Charts UCL LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL www.ePowerPoint.com 1 2 3 4 5 6 Samples over time Control Limits are based on the Normal Curve x m -3 -2 -1 Standard deviation units or “z” units. www.ePowerPoint.com 0 1 2 3 z Control Limits Forming the Upper control limit (UCL) and the Lower control limit (LCL): UCL = Process Mean + 3 Standard Deviations LCL = Process Mean – 3 Standard Deviations UCL +3σ Process Average - 3σ LCL www.ePowerPoint.com time Control Chart Basics Special Cause Variation: Range of unexpected variability UCL Common Cause Variation: range of expected variability +3σ Process Mean - 3σ LCL time UCL = Process Mean + 3 Standard Deviations LCL = Process Mean – 3 Standard Deviations www.ePowerPoint.com Process Variability Special Cause of Variation: A measurement this far from the process average is very unlikely if only expected variation is present UCL ±3σ → 99.7% of process values should be in this range Process Mean LCL time UCL = Process Mean + 3 Standard Deviations LCL = Process Mean – 3 Standard Deviations www.ePowerPoint.com In-control Process A process is said to be in control when the control chart does not indicate any out-of-control condition Contains only common causes of variation If the common causes of variation is small, then control chart can be used to monitor the process If the common causes of variation is too large, you need to alter the process www.ePowerPoint.com Process In Control Process in control: points are randomly distributed around the center line and all points are within the control limits UCL Process Mean LCL time www.ePowerPoint.com Process Not in Control Out of control conditions: One or more points outside control limits 8 or more points in a row on one side of the center line 8 or more points in a row moving in the same direction www.ePowerPoint.com Process Not in Control One or more points outside control limits UCL Process Average Process Average LCL LCL Eight or more points in a row moving in the same direction UCL Process Average LCL www.ePowerPoint.com Eight or more points in a row on one side of the center line UCL Out-of-control Processes When the control chart indicates an out-of-control condition (a point outside the control limits or exhibiting trend, for example) Contains both common causes of variation and assignable causes of variation The assignable causes of variation must be identified If detrimental to the quality, assignable causes of variation must be removed If increases quality, assignable causes must be incorporated into the process design www.ePowerPoint.com Types of Statistical Sampling Attribute (Go or no-go information) Defectives refers to the acceptability of product across a range of characteristics. Defects refers to the number of defects per unit which may be higher than the number of defectives. (good or bad, function or malfunction, 0 or 1) p-chart application Variable (Continuous) Usually measured by the mean and the standard deviation. X-bar and R chart applications www.ePowerPoint.com Example of Constructing a p-Chart: Required Data Sample No. of No. Samples 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 www.ePowerPoint.com 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Number of defects found in each sample 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 Statistical Process Control Formulas: Attribute Measurements (p-Chart) Given: sp = T o ta l N u m b e r o f D e fe c tiv e s p = T o ta l N u m b e r o f O b s e rv a tio n s p (1 - p) n UCL = p + z sp LCL = p - z sp Where p is the fraction defective, s p is the standard deviation, n is the sample size, z is the number of standard deviations for a specific confidence. Typically, z 3 (99.7 percent confidence) or z 2.58 (99 percent confidence) Compute control limits: www.ePowerPoint.com Example of Constructing a p-chart: Step 1 1. Calculate the sample proportions, p (these are what can be plotted on the p-chart) for each sample www.ePowerPoint.com Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 n 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Defectives 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 p 0.04 0.02 0.05 0.03 0.06 0.04 0.03 0.07 0.01 0.02 0.03 0.02 0.02 0.08 0.03 Example of Constructing a p-chart: Steps 2&3 2. Calculate the average of the sample proportions 55 p = 1500 = 0.036 3. Calculate the standard deviation of the sample proportion sp = p (1 - p) = n www.ePowerPoint.com .036(1- .036) = .0188 100 Example of Constructing a p-chart: Step 4 4. Calculate the control limits UCL = p + z sp LCL = p - z sp .036 3(.0188) UCL = 0.0924 LCL = -0.0204 (or 0) www.ePowerPoint.com Example of Constructing a p-Chart: Step 5 5. Plot the individual sample proportions, the average of the proportions, and the control limits 0.1 0.09 0.08 0.07 0.06 p UCL LCL 0.05 0.04 0.03 0.02 0.01 0 1 www.ePowerPoint.com 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Some notes for p-charts The size of the sample must be large enough to allow counting of the attribute. A rule of thumb when setting up a p chart is to make the sample large enough to expect to count the attribute twice in each sample. The assumption is that the sample size is fixed. If the sample size varies, the standard deviation and upper and lower control limits should be recalculated for each sample. www.ePowerPoint.com Some notes for p-charts T o ta l N u m b e r o f D e fe c tiv e s p = T o ta l N u m b e r o f O b s e rv a tio n s UCL = p + z sp LCL = p - z sp nn www.ePowerPoint.com sp = p (1 - p) n Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 www.ePowerPoint.com n 100 50 100 100 75 100 100 50 100 100 100 100 100 100 100 Defectives 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 p 0.04 0.04 0.05 0.03 0.08 0.04 0.03 0.14 0.01 0.02 0.03 0.02 0.02 0.08 0.03 Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 www.ePowerPoint.com n 100 50 100 100 75 100 100 50 100 100 100 100 100 100 100 n-bar 91.66666667 UCL LCL Defectives 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 sum defects 55 0.101401806 -0.021401806 p 0.04 0.04 0.05 0.03 0.08 0.04 0.03 0.14 0.01 0.02 0.03 0.02 0.02 0.08 0.03 p-bar 0.04 sp 0.020467 0.16 0.14 0.12 0.1 p UCL LCL 0.08 0.06 0.04 0.02 0 1 2 3 www.ePowerPoint.com 4 5 6 7 8 9 10 11 12 13 14 15 Process Control With Variable Measurements: Using X-bar and R Charts Size of the samples (keep the sample size small, 4-5 is preferred) the sample needs to be taken within a reasonable length of time the larger the sample, the more it costs to take. Number of samples (25 or so samples is suggested to set up the chart) Frequency of samples Control limits www.ePowerPoint.com Example of x-bar and R Charts: Required Data Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Obs 1 10.68 10.79 10.78 10.59 10.69 10.75 10.79 10.74 10.77 10.72 10.79 10.62 10.66 10.81 10.66 www.ePowerPoint.com Obs 2 10.689 10.86 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 Obs 3 10.776 10.601 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 Obs 4 10.798 10.746 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 Obs 5 10.714 10.779 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 Example of x-bar and R charts: Step 1. Calculate sample means, sample ranges, mean of means, and mean of ranges. 3 4 5 6 7 8 9 10 11 12 13 14 15 10.78 10.59 10.69 10.75 10.79 10.74 10.77 10.72 10.79 10.62 10.66 10.81 10.66 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 Averages www.ePowerPoint.com 10.759 10.727 10.724 10.705 10.735 10.624 10.710 10.732 10.748 10.768 10.733 10.783 10.692 0.171 0.221 0.119 0.143 0.274 0.669 0.132 0.179 0.163 0.250 0.349 0.158 0.103 10.728 0.220400 Example of x-bar and R charts: Step 2. Determine Control Limit Formulas and Necessary Tabled Values E.L.Grant and R.Leavenworth computed a table, where n is the number of observations in subgroup, A2 is the factor for X-bar chart, D3 and D4 are factors for R chart. x Chart Control Limits UCL = x + A 2 R LCL = x - A 2 R R Chart Control Limits UCL = D 4 R LCL = D 3 R www.ePowerPoint.com n 2 3 4 5 6 7 8 9 10 11 A2 1.88 1.02 0.73 0.58 0.48 0.42 0.37 0.34 0.31 0.29 D3 0 0 0 0 0 0.08 0.14 0.18 0.22 0.26 D4 3.27 2.57 2.28 2.11 2.00 1.92 1.86 1.82 1.78 1.74 Example of x-bar and R charts: Steps 3&4. Calculate x-bar Chart and Plot Values UCL = x + A 2 R 10.728 - .58(0.2204 ) = 10.856 LCL = x - A 2 R 10.728 - .58(0.2204 ) = 10.601 10.900 UCL 10.850 Means 10.800 10.750 10.700 Central Line LCL 10.650 10.600 10.550 1 2 www.ePowerPoint.com 3 4 5 6 7 8 Sample 9 10 11 12 13 14 15 Example of x-bar and R charts: Steps 5&6. Calculate R-chart and Plot Values UCL = D 4 R (2.11)( 0.2204 ) 0.46504 LCL = D 3 R (0)( 0.2204 ) 0 0 .8 0 0 0 .7 0 0 0 .6 0 0 0 .5 0 0 R UCL 0 .4 0 0 0 .3 0 0 0 .2 0 0 R 0 .1 0 0 LCL 0 .0 0 0 1 2 www.ePowerPoint.com 3 4 5 6 7 8 S a m p le 9 10 11 12 13 14 15 The R Chart Monitors variability in a process The characteristic of interest is measured on a numerical scale Is a variables control chart Shows the sample range over time Range = difference between smallest and largest values in the subgroup www.ePowerPoint.com The R Chart 1. Find the mean of the subgroup ranges (the center line of the R chart) 2. Compute the upper and lower control limits for the R chart 3. Use lines to show the center and control limits on the R chart 4. Plot the successive subgroup ranges as a line chart www.ePowerPoint.com The X Chart Shows the means of successive subgroups over time Monitors process average Must be preceded by examination of the R chart to make sure that the variation in the process is in control www.ePowerPoint.com The X Chart Compute the mean of the subgroup means (the center line of the X chart) Compute the upper and lower control limits for the X chart Graph the subgroup means Add the center line and control limits to the graph www.ePowerPoint.com