Ch_1_2_s01_605

advertisement

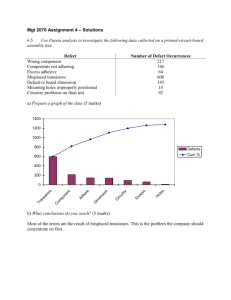

Quality and Education Business has made progress toward quality over the past several years. But I don’t believe we can truly make quality a way of life … until we make quality a part of every student’s education Edwin Artzt, Chairman and CEO, Proctor & Gamble Co., Quality Progress, October 1992, p. 25 1 Quality and Competitive Advantage • Better price – The better customers judge the quality of a product, the more they will pay for it • Lower production cost – It is cheaper to do a job right the first time than do it over • Faster response – A company with quality processes for handling orders, producing products, and delivering them can provide fast response to customer requests 2 Quality and Competitive Advantage • Reduced Inventory – When the production line runs smoothly with predictable results, inventory levels can be reduced • Improved competitive position in the marketplace – A customer who is satisfied with quality will tell 8 people about it; a dissatisfied customer will tell 22 (A.V. Feigenbaum, Quality Progress, February 1986, p. 27) 3 TQM Wheel Customer satisfaction 4 Customer-Driven Definitions of Quality • Conformance to specifications – Conformance to advertised level of performance • Value – How well the purpose is served at a particular price. – For example, if a $2.00 plastic ballpoint pen lasts for six months, one may feel that the purchase was worth the price. 5 Customer-Driven Definitions of Quality • Fitness for use – Mechanical feature of a product, convenience of a service, appearance, style, durability, reliability, craftsmanship, serviceability • Support – Financial statements, warranty claims, advertising • Psychological Impressions – Atmosphere, image, aesthetics – “Thanks for shopping at Wal-Mart” 6 Defectives and Defect • In the popular sense, a defect is some characteristic that makes a product unsatisfactory for its intended purpose • Technically, a defect is a failure to conform to some specification e.g., 0.140 0.003 in. • To avoid ambiguity, following words are suggested – Nonconformity or Nonconformance: defect – Nonconforming: defective 7 Quality Costs • Prevention costs – Customer requirements/expectations market research – Product design/development reviews – Quality education programs – Equipment and preventive maintenance – Supplier-rating program administration 8 Quality Costs • Appraisal costs – Testing/inspection equipment – Inspection costs – Audits 9 Quality Costs • Internal failure costs – Rework, scrap, repair • External failure costs – Returned goods, warranty costs, liability costs, penalties • Intangible costs – Customer dissatisfaction, company image, lost sales, loss of customer goodwill 10 Cost of detection (dollars) Costs of Detecting Defects Process Final testing Customer When defect is detected 11 Statistical Quality Control Introduction • • • • Control charts and sampling Simple X and R charts Variation Common and assignable causes 12 Control Chart Viewpoint • Variation due to – Common or chance causes – Assignable causes • Control chart may be used to discover “assignable causes” 13 Scientific Sampling • Inspection – Incoming materials, in-process products, finished goods • JIT inventory control makes formal sampling impractical except for quality audit purposes – The supplier performs sampling inspection and provides statistical evidence of conformance to specifications • 100% inspection may be impractical or uneconomical 14 Some Terms • Run chart - without any upper/lower limits • Specification/tolerance limits - not statistical • Control limits - statistical 15 Weakness of Plotting Individual Measurements against Specification/Tolerance Limits • If individual measurements are plotted against specification/tolerance limits, following problems may occur – If specification/tolerance limits are too wide, the systems may fail to detect some variations that are less likely to be caused by chance and more likely to be caused by some problems in the production system (see Example 1.1) – If specification/tolerance limits are too narrow, unavoidable random variations may be considered as defects and too many items may be rejected (see Example 1.2) 16 Control Charts • Take periodic samples from a process • Plot the sample points on a control chart • Determine if the process is within limits • Correct the process before defects occur 17 Types of Data • Variable data • Product characteristic that can be measured • Length, size, weight, height, time, velocity • Attribute data • Product characteristic evaluated with a discrete choice • Good/bad, yes/no 18 Process Control Chart Upper control limit Process average Lower control limit 1 2 3 4 5 6 Sample number 7 8 10 9 19 Constructing a Control Chart • • • • • • Decide what to measure or count Collect the sample data Plot the samples on a control chart Calculate and plot the control limits on the control chart Determine if the data is in-control If non-random variation is present, discard the data (fix the problem) and recalculate the control limits 20 Control Charts For Variables • Mean chart (X-Bar Chart) –Measures central tendency of a sample • Range chart (R-Chart) –Measures amount of dispersion in a sample • Each chart measures the process differently. Both the process average and process variability must be in control for the process to be in control. 21 Example: Control Charts for Variable Data Sample 1 2 3 4 5 6 7 8 9 10 Slip Ring Diameter (cm) 1 2 3 4 5.02 5.01 4.94 4.99 5.01 5.03 5.07 4.95 4.99 5.00 4.93 4.92 5.03 4.91 5.01 4.98 4.95 4.92 5.03 5.05 4.97 5.06 5.06 4.96 5.05 5.01 5.10 4.96 5.09 5.10 5.00 4.99 5.14 5.10 4.99 5.08 5.01 4.98 5.08 5.07 5 4.96 4.96 4.99 4.89 5.01 5.03 4.99 5.08 5.09 4.99 X R 4.98 0.08 5.00 0.12 4.97 0.08 4.96 0.14 4.99 0.13 5.01 0.10 5.02 0.14 5.05 0.11 5.08 0.15 5.03 0.10 50.09 1.15 Normal Distribution Review • If the diameters are normally distributed with a mean of 5.01 cm and a standard deviation of 0.05 cm, find the probability that the sample means are smaller than 4.98 cm or bigger than 5.02 cm. 23 Normal Distribution Review • If the diameters are normally distributed with a mean of 5.01 cm and a standard deviation of 0.05 cm, find a lower value and an upper value of the sample means such that 97% sample means are between the lower and upper values. 24 Normal Distribution Review • Define the 3-sigma limits for sample means as follows: 3 3(0.05) Upper Limit 5.01 5.077 n 5 3 3(0.05) Lower Limit 5.01 4.943 n 5 • What is the probability that the sample means will lie outside 3-sigma limits? 25 Normal Distribution Review • Note that the 3-sigma limits for sample means are different from natural tolerances which are at 3 26 Constructing a Range Chart UCL R D4 R ( 2.11)( 0.115) 2.43 LCLR D3 R (0)( 0.115) 0 where R R / k 1.15 / 10 0.115 k number of samples 10 R range (see p. 29 or Text Table D, App. for the values of D3 , D4 ) Note: The control limits are only preliminary with 10 samples. It is desirable to have at least 25 samples. 27 Constructing A Mean Chart UCL X X A2 R (5.01) 0.58(0.115) 5.077 LCL X X A2 R (5.01) 0.58(0.115) 4.943 where X X / k 50.09 / 10 5.01 R R / k 1.15 / 10 0.115 k number of samples 10 R range (see p. 29 or Text Table D, App. 3 for the value of A2 ) 28 3-Sigma Control Chart Factors Sample size n 2 3 4 5 6 7 8 X-chart A2 1.88 1.02 0.73 0.58 0.48 0.42 0.37 R-chart D3 0 0 0 0 0 0.08 0.14 D4 3.27 2.57 2.28 2.11 2.00 1.92 1.86 29 Common Causes 30 Assignable Causes Average (a) Mean Grams 31 Assignable Causes Average (b) Spread Grams 32 Assignable Causes Average (c) Shape Grams 33 The Normal Distribution = Standard deviation Mean -3 -2 -1 +1 +2 +3 68.26% 95.44% 99.74% 34 Control Charts Assignable causes likely UCL Nominal LCL 1 2 Samples 3 35 Control Chart Examples Variations UCL Nominal LCL Sample number 36 Control Limits and Errors Type I error: Probability of searching for a cause when none exists UCL Process average LCL (a) Three-sigma limits 37 Control Limits and Errors Type I error: Probability of searching for a cause when none exists UCL Process average LCL (b) Two-sigma limits 38 Control Limits and Errors Type II error: Probability of concluding that nothing has changed UCL Shift in process average Process average LCL (a) Three-sigma limits 39 Control Limits and Errors Type II error: Probability of concluding that nothing has changed UCL Shift in process average Process average LCL (b) Two-sigma limits 40 Process Capability • Range of natural variability in process – Measured with control charts • Process cannot meet specifications if natural variability exceeds tolerances • 3-sigma quality – specifications equal the process control limits. • 6-sigma quality –specifications twice as large as control limits 41 Natura l control limits Design specs PROCESS Process cannot meet specifications PROCESS PROCESS Process Capability Natural control limits Process can meet specifications Natural control limits Design specs Process capability exceeds specifications 42 Process Capability • If the R chart shows control, estimate the standard deviation of items as R d • If the R chart does not show control, remove the ones that showed lack of control, calculate a revised R and new control limits for R. Repeat the process as long as it is needed. Estimate standard deviation of items as shown above. X LSL USL X x x , • Process capability C pk min 3 3 43 Process Capability • By computing C pk we can conclude whether the mean has shifted towards upper/lower specification limit and if it has shifted at all. If both the numbers are equal, the mean is at the center. If the first number is smaller, the mean has shifted towards LSLx. If the second number is smaller, the mean has shifted towards USLx. • If C pk 1 then the process is capable of producing 99.74% items within the specification limits. Else, either the process needs improvement or the specification limits must be widened. 44 Text Exercise 2.2: Is the following process capable?: Sample size, n 4 Number of samples, k 20 X 41.340, R 0.320 Specification limits are 2.050 0.020 45 Reading and Exercises • Chapter 1: – pp. 3-24 • Chapter 2: – pp. 37-54 – Problems 2.5, 2.6, 2.10 46