Statistical Process Control

advertisement

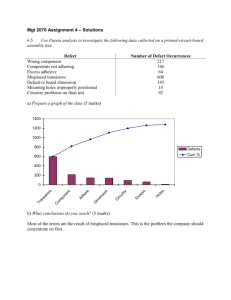

Tech Math 2 Notes Section 22.5 Page 1 of 4 Section 22.5: Statistical Process Control Statistics can be used to monitor and control manufacturing processes to ensure that quality products are being produced. There are two types of control employed: one in which a quantity, or variable, is measured (like the diameter of tires made on an assembly line), and another in which a characteristic, or attribute, is counted (like how many parts are defective). Control of a variable 1. Take a series of multiple measurements of the variable being measured. 2. Calculate the mean ( x )for each group. 3. Calculate the range (R) of each group. 4. Calculate the mean of the means ( x ) (i.e., average up all your averages). 5. Calculate the mean of the ranges ( R ) (i.e., average up all the ranges). 6. Calculate the upper control limit for the variable x ( UCL( x ) ) using the formula UCL( x ) = x + A2 R , where A2 comes from Table 22.2. 7. Calculate the lower control limit for the variable x ( LCL( x ) ) using the formula LCL( x ) = x – A2 R , where A2 comes from Table 22.2. 8. Make an “ x chart” by plotting the mean for each group vs. each group’s number. Draw a solid horizontal line at the value of x and dashed horizontal lines at the values of UCL( x ) and LCL( x ). This chart shows how every group of measurements deviates from the overall average and which group of measurements are outside the acceptable range. 9. Calculate the upper control limit for the range R ( UCL(R) ) using the formula UCL(R) = D4R, where D4 comes from Table 22.2. 10. Calculate the lower control limit for the range R ( LCL(R) ) using the formula LCL(R) = D3R, where D3 comes from Table 22.2. 11. Make an “R chart” by plotting the range for each group vs. each group’s number. Draw a solid horizontal line at the value of R and dashed horizontal lines at the values of UCL(R) and LCL(R). This chart shows how the range of every group of measurements deviates from the average range and which groups of measurements have ranges that are unacceptable. Practice these steps on the data on the following page. Tech Math 2 Notes Section 22.5 Page 2 of 4 Tech Math 2 Notes Section 22.5 Page 3 of 4 Control of an Attribute 1. Take a series of data by counting the portion that are defective (or whatever) out of a large group. 2. Calculate the proportion p that are defective for each group by dividing the count by the sample size. 3. Calculate p , the mean of the proportions. 4. Calculate p, the standard deviation using the formula p p 1 p n , where n is the size of each sample group. 5. Calculate the upper control limit for the proportion p ( UCL(p) ) using the formula UCL(p) = p + 3p. 6. Calculate the lower control limit for the proportion p ( LCL(p) ) using the formula LCL(p) = p – 3p. 7. Make a “p control chart” by plotting the proportion for each group vs. each group’s number. Draw a solid horizontal line at the value of p and dashed horizontal lines at the values of UCL(p) and LCL(p). This chart shows how the proportion for every group deviates from the average proportion, and which proportions are outside the acceptable range. Practice these steps on the data on the following page. Tech Math 2 Notes Section 22.5 Page 4 of 4