PowerPoint

advertisement

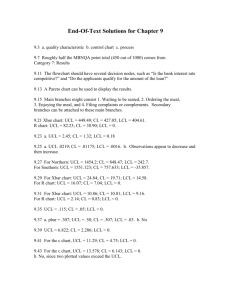

Process Capability and Statistical Process Control 1. 2. 3. Explain what statistical quality control is. Calculate the capability of a process. Understand how processes are monitored with control charts for both attribute and variable data How many paint defects are there in the finish of a car? How long does it take to execute market orders? How well are we able to maintain the dimensional tolerance on our ball bearing assembly? How long do customers wait to be served from our drive-through window? LO 1 Assignable variation: caused by factors that can be clearly identified and possibly managed ◦ Example: a poorly trained employee that creates variation in finished product output Common variation: variation that is inherent in the production process ◦ Example: a molding process that always leaves “burrs” or flaws on a molded item LO 1 When variation is reduced, quality is improved However, it is impossible to have zero variation ◦ Engineers assign acceptable limits for variation ◦ The limits are know as the upper and lower specification limits Also know as upper and lower tolerance limits LO 1 LO 1 Traditional view is that quality within the range is good and that the cost of quality outside this range is constant Taguchi views costs as increasing as variability increases, so seek to achieve zero defects and that will truly minimize quality costs Taguchi argues that tolerance is not a yes/no decision, but a continuous function Other experts argue that the process should be so good the probability of generating a defect should be very low LO 2 Process limits Specification limits How do the limits relate to one another? LO 2 LO 2 Capability index (Cpk) shows how well parts being produced fit into design limit specifications X LT L UT L- X C pk = min or 3 3 Also useful to calculate probabilities Z LTL LO 2 LTL X ZUTL UTL X Data ◦ Designed for an average of 60 psi Lower limit of 55 psi, upper limit of 65 psi ◦ Sample mean of 61 psi, standard deviation of 2 psi Calculate Cpk C pk x LSL USL x min , 3 3 61 55 65 61 min , 3 2 3 2 min1, 0.6667 0.6667 LO 2 Less than 55 psi X X 55 61 Z 3 2 P( Z 3) 0.00135 More than 65 psi X X 65 61 Z 2 2 P( Z 2) 0.02275 LO 2 P( Z 3 or Z 2) 0.00135 0.02275 0.02410 LO 2 We are the maker of this cereal. Consumer Reports has just published an article that shows that we frequently have less than 15 ounces of cereal in a box. Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. Upper Tolerance Limit = 16 + .05(16) = 16.8 ounces Lower Tolerance Limit = 16 – .05(16) = 15.2 ounces We go out and buy 1,000 boxes of cereal and find that they weight an average of 15.875 ounces with a standard deviation of .529 ounces. Specification or Tolerance Limits ◦ Upper Spec = 16.8 oz ◦ Lower Spec = 15.2 oz C pk Observed Weight ◦ Mean = 15.875 oz ◦ Std Dev = .529 oz X LTL UTL X Min ; 3 3 15.875 15.2 16.8 15.875 C pk Min ; 3(.529) 3(.529) C pk Min.4253; .5829 C pk .4253 LO 2 An index that shows how well the units being produced fit within the specification limits. This is a process that will produce a relatively high number of defects. Many companies look for a Cpk of 1.3 or better… 6-Sigma company wants 2.0! LO 2 Attribute (Go or no-go information) ◦ Defectives refers to the acceptability of product across a range of characteristics. ◦ Defects refers to the number of defects per unit which may be higher than the number of defectives. ◦ p-chart application Variable (Continuous) ◦ Usually measured by the mean and the standard deviation. ◦ X-bar and R chart applications LO 3 Statistical Process Normal Behavior Control (SPC) Charts UCL LCL 1 2 3 4 5 6 UCL Samples over time Possible problem, investigate LCL 1 2 3 4 5 6 UCL Samples over time Possible problem, investigate LCL 1 LO 3 6 2 3 4 5 Samples over time x m -3 -2 -1 Standard deviation units or “z” units. LO 3 0 1 2 3 z We establish the Upper Control Limits (UCL) and the Lower Control Limits (LCL) with plus or minus 3 standard deviations from some xbar or mean value. Based on this we can expect 99.73% of our sample observations to fall within these limits. 99.73% LCL LO 3 UCL x Created for good/bad attributes Use simple statistics to create the control limits T otalnumber of defectsfromall samples p Number of samples Sample size sp p 1 p n UCL p zs p LCL p zs p LO 3 LO 3 1 – 2- 5- 7 Rule 1 point above UCL or 1 point below LCL 2 consecutive points near the UCL or 2 consecutive points near the LCL 5 consecutive decreasing points or 5 consecutive increasing points 7 consecutive points above the center line or 7 consecutive points below the center line LO 3 T otalnumber of defectsfromall samples 91 p 0.03033 Number of samples x Sample size 3,000 sp p 1 p 0.030331 0.03033 0.00990 n 300 UCL p 3s p 0.03033 30.00990 0.06003 LCL p 3s p 0.03033 30.00990 0.00063 LO 3 LO 3 In variable sampling, we measure actual values rather than sampling attributes Generally want small sample size 1. Quicker 2. Cheaper Samples of 4-5 are typical Want 25 or so samples to set up chart LO 3 UCLX X zs X LCLX X zs X where s s X St andard deviationof samplemeans n s St andard deviationof theprocessdist ribution n Sample size X Averageof samplemeansor a target value set for theprocess z Number of standarddeviationsfor a specificconfidencelevel LO 3 X Chart UCLX X A2 R LCLX X A2 R R Chart UCLR D4 R LCLR D3 R LO 3 LO 3 LO 3 LO 3