Exp.4: Rubber in Shear Apparatus

advertisement

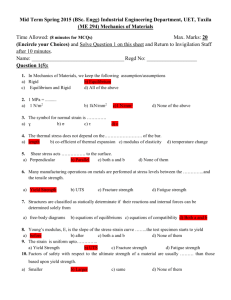

Exp.4: Rubber in Shear Apparatus Eng. Ahmed Y Manama Eng. Saeed A Shurab Eng. Ahmed Al Afeefy Objectives Measure the shear deformation of the block. Determine of modulus of rigidity. Introduction Rubber blocks in shear force are often used on engine and in equipment mounting to isolate vibrations. They do this by absorbing shock energy by deforming. This deformation leads to a decrease in cross-section as the block lengthens, an effect described by Poisson's Ratio. Introduction Shear Stress and Strain Introduction The force F acting at angle theta with respect to the horizontal , the force resolved to it’s component ( perpendicular and parallel to the surface area). The perpendicular component will produce an Axial Stress The parallel component will effect the rod by producing a Shear Stress. The units of both Axial and Shear Stress will normally be lb/in2 or N/m2 Introduction Shear Strain The shear stress produces a displacement of the rod which produces a shear strain. The edge of the rod is displaced a horizontal distance, from its initial position ,this displacement (or horizontal deformation) divided by the length of the rod L is equal to the Shear Strain. Introduction Introduction Tan γ = γ = δ / L Where : δ is the deformation γ shear strain L original length The shear strain is dimensionless. Shear Modulus (Modulus of Rigidity) The modulus of rigidity ( shear modulus) (denoted by G or sometimes S or μ,) is concerned with the deformation of a solid when it experiences a force parallel to one of its surfaces while its opposite face experiences an opposing force (such as friction). Shear modulus is usually measured in GPa or ksi (thousands of pounds per square. Shear Modulus (Modulus of Rigidity) It’s defined as the ratio of shear stress to the shear strain: where F is the force which acts A is the area on which the force acts Δx is the transverse displacement I is the initial length Equipment A rubber block 150 x 75 x 25mm is bonded to two aluminum alloy plates. Results Load (N) 0 10 20 30 40 50 60 70 80 90 100 110 120 Dial Gauge (mm) Deflection (mm)