Supplier Quality Material Report - L

advertisement

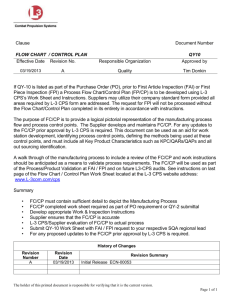

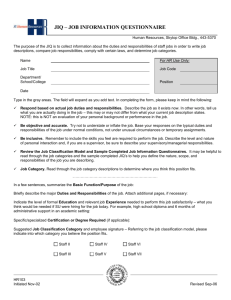

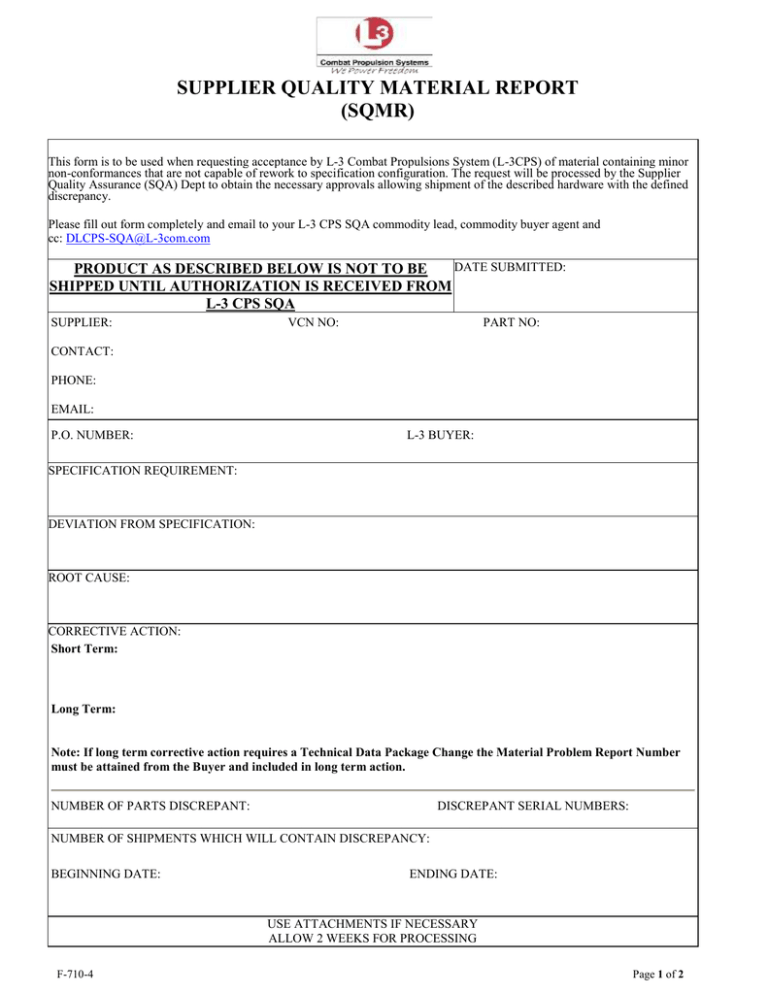

SUPPLIER QUALITY MATERIAL REPORT (SQMR) This form is to be used when requesting acceptance by L-3 Combat Propulsions System (L-3CPS) of material containing minor non-conformances that are not capable of rework to specification configuration. The request will be processed by the Supplier Quality Assurance (SQA) Dept to obtain the necessary approvals allowing shipment of the described hardware with the defined discrepancy. Please fill out form completely and email to your L-3 CPS SQA commodity lead, commodity buyer agent and cc: DLCPS-SQA@L-3com.com DATE SUBMITTED: PRODUCT AS DESCRIBED BELOW IS NOT TO BE SHIPPED UNTIL AUTHORIZATION IS RECEIVED FROM L-3 CPS SQA SUPPLIER: VCN NO: PART NO: CONTACT: PHONE: EMAIL: P.O. NUMBER: L-3 BUYER: SPECIFICATION REQUIREMENT: DEVIATION FROM SPECIFICATION: ROOT CAUSE: CORRECTIVE ACTION: Short Term: Long Term: Note: If long term corrective action requires a Technical Data Package Change the Material Problem Report Number must be attained from the Buyer and included in long term action. NUMBER OF PARTS DISCREPANT: DISCREPANT SERIAL NUMBERS: NUMBER OF SHIPMENTS WHICH WILL CONTAIN DISCREPANCY: BEGINNING DATE: ENDING DATE: USE ATTACHMENTS IF NECESSARY ALLOW 2 WEEKS FOR PROCESSING F-710-4 Page 1 of 2 SQMR FORM INSTRUCTIONS FOR COMPLETING 1. SUPPLIER 2. VCN NO. 3. PART NO. 4. P.O. NUMBER 5. L-3 BUYER 6. CONTACT 7. PHONE NO. 8. E-MAIL ADDRESS 9. SPECIFICATION REQUIREMENT 10. DEVIATION FROM SPECIFICATION 11. ROOT CAUSE 12. CORRECTIVE ACTION Enter the name of your company Enter the "Supplier Number" from the top of the Purchase Order (PO) enter the L-3 CPS Part Number of the material being submitted Enter the PO number Enter the L-3 BUYER AGENT Enter the name of the person in your organization who is knowledgeable of the issue and may be contacted if necessary to answer questions concerning the request. Enter the complete phone no. for the contact (incl ext) Enter the E-Mail address for the contact State the drawing/spec requirement (with tolerance) If more than one use alpha designators State the out of tolerance condition for each designator. State the cause for the out of tolerance condition for each designator Short Term Explain the immediate correction to preclude additional product from containing the same discrepancy associated with each designator Long Term Describe the systemic closed loop correction (include implementation dates) associated with each designator. Note: If long term corrective action requires a Technical Data Package Change the Material Problem Report Number must be attained from the Buyer and included in long term action. 13. QUANTITY OF PARTS DISCREPANT 14. SERIAL NOS OF DISCREPANT PARTS 15. NUMBER OF SHIPMENTS WHICH WILL CONTAIN DISCREPANCY 16. BEGINNING DATE 17. ENDING DATE F-710-4 For each designator, list the quantity of parts discrepant Enter the serial nos.of the discrepant parts if applicable If at all possible, it is preferred the discrepant lot be shipped as a single shipment. Enter the anticipated date of the first shipment of discrepant material. Enter the anticipated date of the final shipment of discrepant material. NOTE: If approved for shipment, discrepant material must be shipped as its own lot and not co-mingled with conforming material. Page 2 of 2