SWP_RotaryEvaporatorsv4

advertisement

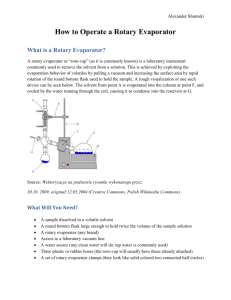

OHS026 1. Completed by: Dr. Pall Thordarson Safe work procedure Staff/Student number: The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form Faculty/Division: Faculty of Science Document number F10-SWP-170 School/Unit: School of Chemistry Initial Issue date: 13-May 2011 Current version: V1.1 Current Version Issue date: 31-August 2011 Next review date: 31-August 2013 2.Safe work procedure title and basic description of activity Title: Rotary Evaporator Description of activity: Proper usage of Rotary Evaporators 3.List Hazards and risk controls as per risk assessment Associated risk assessment number and location: Hazards: Physical injury due to spinning rotor Controls Proper training, proper and regular maintenance; avoid touching the rotating parts of the equipment, specially the connector between the distillation flask and the rotor. Avoid loose clothing or hair as this may get caught in any of the rotating parts of the equipment. F10-RA-170 See School of Chemistry Safety Page and Faculty of Science Database Physical injury due to handling or implosion or explosion of glass Proper training, proper and regular maintenance; ALWAYS check glassware for cracks, scratches and other imperfections (see also SWP for handling glassware). Use only heavy walled glass or Pyrex ® round bottom flask or specially manufactured flasks. Check plastic coating on condenser and receiving flask. Flasks larger than 1 L should be enclosed in tape or plastic mesh. If a cooling dewar is used, ensure it is also covered in tape, plastic mesh or in a metal container (see also SWP for cryogenic cooling). Use gloves preferably leather and other appropriate PPE such as protective safety glasses and a laboratory coat when handling glass ware. Check MSDS of chemical you are using for explosion risk – some chemicals may explode up on drying and fill in the corresponding School of Chemistry Risk assessment form. Burns from hot water / heating bath Proper training, proper and regular maintenance; Make sure that water bath is filled to the appropriate level (ca. 2/3 in most cases). NEVER test the temperature of water with your hand. Avoid touching heating bath. Spillage and contamination, from solvents and samples used Proper training; consult MSDS for the solvents and chemicals you are using and fill in the corresponding School of Chemistry Risk assessment form. Use gloves and other PPE at all times. Decant solvents when possible in a fume hood and dispose of solvents thoughtfully into the appropriate waste container – for noxious or highly toxic solvent such as thinoyl chloride, pyridines, organic acids and thiols this MUST be done in a fume hood. Ensure that vacuum exhaust is carried away by the buildings in-house vacuum system or to the back of a fume-hood. Flooding due to leaking hoses Proper training, proper and regular maintenance; Ensure that the correct type of hosing is used and that it is in good condition. Red Vacuum hosing should NEVER be used for water. Ensure all fittings are secured with a wire or cable ties. Ensure that all water taps are turned off immediately after use. Check that water taps have been closed when leaving the laboratory. If flooding does occur NEVER touch any part of the equipment until the power has been turned off the laboratory using the emergency cutoff switch (red button) for the laboratory (e.g.,, lF10-234). Potential electrical hazard Annual inspection of electrical equipment and ensure inspection tag is current. Ensure all precautions are taken to avoid flooding (see v) as water around the rotary evaporator equipment can results in electrocution. If flooding does occur NEVER touch any part of the equipment until the power has been turned off the laboratory using the emergency cutoff switch (red button) for the laboratory (e.g.,, lF10-234). _______________________________________________________________________________________________________________ Page 1 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 4.List resources required including personal protective clothing, chemicals and equipment needed Materials and Equipment • Rotary Evaporators (e.g., Buchi, Heidolph). Diaphragm vacuum pump. • Solvents that is to be removed (hexane, ethyl acetate, dichloromethane and methanol the most common ones) • The sample/product that the solvent is to be removed from. • Appropriate round bottom flasks or specially made rotary evaporation flasks Personal Protective Clothing and Equipment • Protective safety glasses • Laboratory coat • Gloves (choose according to chemical compatibility and/or physical hazard) 5.List step by step instructions or order for undertaking the task Operation • Only suitably trained persons may operate a rotary evaporator. • Before use, the rotary evaporator must be examined for signs of cracks in glassware and that water hoses are in good condition and properly secured with wire or cable ties. • The receiver flask should be empty and the glassware interior clean before use. • Check the water bath and refill with distilled / demi water (reduces scale build-up) if necessary but no more than about 2/3-3/4 or less if planning to use a large distillation flask. • NEVER fill the distillation flask. A level of no more than 2/3 is recommended – for solvents or solutions that can “bump” use less. Consider to add boiling chips if severe bumping is expected. • Open the air valve on the condenser to air. Turn on the cooling water and the vacuum source (a vacuum pump or the house vacuum). Ensure the exhaust hoses or system is open/on. If you are using the newer models of rotary evaporators with vacuum pump and a controller, select the target pressure according to the main solvent you are using (consult manual if necessary). • Check that you have the right adapters for your distillation flask, and if you want to use them, the correct size securing clips. • Mount the distillation flask on the rotary evaporator. Secure with clips if using them but note that they are not designed to hold the weight of a large/full distillation flask. For this reason, hold the flask at all times with one hand until you have closed the air valve on the condenser and a vacuum has formed holding the flask in place. Then let slowly go off the distillation flask but keep it still under the flask. Turn on the rotary motor – if the flask stays on after it starts to rotate, take your hand away from the distillation flask. • Lower the flask carefully to the water bath using the “lift” on your equipment (different configurations on different models – consult manual if necessary). Take care not to slam the rotating glass connector or distillation flask on to the rim of the water bath. Take note of the water level as you lower the flask so that the water doesn’t overflow. • Turn on the water bath and adjust the temperature. For manual system a temperature of at least 20 degrees below the atmospheric boiling point is recommended. Temperatures above 60 degrees should be avoided but if you think it absolutely necessary, ensure to check the water level regularly and that the resulting steam created does not create hazards or inconveniences for people in the surroundings. • Check the rotary evaporator regularly while it is running. Check the water bath levels, and the water hoses and condensers for leaks. Check that the exhaust is working properly. • When the distillation is finished, turn off the water bath and the rotary motor. Carefully raise the “lift” from the water bath. With one hand ready to support the flask (CAREFUL – GLASSWARE MIGHT BE HOT!), release the vacuum by opening the air valve on the condenser. Carefully take the distillation flask off by slight twist and then down-wards movement. If the joint is stuck, a slight twist often undoes it. If the joint is “frozen” consult SWP for frozen glass joint. • Turn off the vacuum source and exhaust system (if applicable). • Turn off the cooling water. • Empty the receiver flask into the appropriate (waste) container. Rinse the glass joint using a damp wipe, both on the outside and inside. In extreme cases a spray bottle with acetone or ethanol may be required – in that case, use a beaker to collect the rinse / excess solvent. The rotary can also be cleaned by “distilling” 50-100 mL of acetone or ethanol. In extreme cases the condenser may have to be disassembled for cleaning – consult operation manual. Regular maintenance • Check water hoses, wiring of hoses and connectors. Replace hoses regularly. • Check glassware for cracks and other sign of wear. • Check vacuum connectors and hoses. • Check electrical connections for wear and tear. They also need to be tested regularly. _______________________________________________________________________________________________________________ Page 2 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 • The “O-ring” seal between the condenser and the rotor needs to be checked regularly. To do this you need to carefully remove the condenser assembly – consult the equipment manual (n.b. if the rotary evaporator is not as effective as it used to be and no other sources of vacuum leaks or problem can be identified, the O-ring seal is usually the culprit). 6.List emergency shutdown procedures Turn off power at power point. If unable or unsafe to do so, use the emergency cut-off switch (red button) for the laboratory (e.g., lF10-234) usually located on the wall near the entrance to the lab. After turning off power, turn the water and house vacuum (if in use) off if it safe to do so. 7.List Emergency procedures for how to deal with fires, spills or exposure to hazardous substances Contain the fire or spillage if safety of all personnel is not compromised, otherwise shutdown the power using the emergency cut-off switch (red button) for the laboratory (e.g.,, lF10-234) and call the security for emergency (x56666). 8.List Clean up and waste disposal requirements If a distillation flask or a receiver flask breaks or their contents are somehow otherwise spilled, take all necessary steps to avoid contact with broken glass or hazardous chemicals and solvents. Ensure others around you are warned about the hazard. Clean up the spill but only if it safe to do and dispose of glass and chemicals in the appropriate waste containers. A chemical spill may be treated with Vermiculate or by rinsing with copious amounts of water – consult MSDS for advice. In the event of a significant spill that cannot be safely contained, ask everyone to evacuate the laboratory. Contact the Laboratory Manager, Supervisor or another Senior Person for assistance. If the spill might be threatening to others in the building or the environment, call the security for emergency (x56666). 9.List legislation used in the development of this SWP NSW OHS Act 2000, NSW OHS Regulation 2001, Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.3:2006 Safety in Laboratories Part 7 Electrical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance 10a.List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: All personnel operating this equipment must have training and instructions on the safe use of the equipment and they must be assessed as competent. 10b. List competency of Assessor Academic supervisor, post-doctoral fellow or senior PhD student (minimum 1 year into PhD). 11.Supervisory approval, And review Note: Local supervisor must determine appropriate authorisation and final sign off when this document is downloaded. Supervisor: Responsibility for SWP review: Signature: Date of review: 12.SWP Sign off sheet SWP name and version: _______________________________________________________________________________________________________________ Page 3 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011 In signing this section the assessor/ authorisor agrees that the following persons are competent in following this SWP Name Signature Date Competent Name of Assessor/Authoriser Assessor/Authoriser signature _______________________________________________________________________________________________________________ Page 4 of 4 OHS026 safe work procedure Current Version: 3.0, 04/03/2011