STANDARD OPERATING PROCEDURE BIBBY STERILIN RE-100

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

Ref. No.

SOP/PD/317_02

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Valid for:

2 years from approval

Table of Contents

1.

Scope

2.

Objective

Page

2

2

3.

Definitions

4.

Responsibility

7.

References

2

2

5.

Procedure 3

5.1. Diagram of Bibby Sterilin

®

Rotary Evaporator RE-100 3

5.2. Installation

5.3. Operation

4

5

5.4. Maintenance

5.5. Troubleshooting

5.6. Flow Charts

6.

Precautions

7

8

9

15

15

8.

Appendices 15

9.

Revision History 16

Page 1 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

1.

Scope

This Standard Operating Procedure (SOP) applies to the staff and students using the Bibby Sterilin

®

RE-100 Rotary Evaporator in the laboratories of the

Pharmacy Department, University of Malta.

2.

Objective

To describe the procedure for the installation, operation and maintenance of the Bibby Sterilin

®

RE-100 Rotary Evaporator.

3.

Definitions

3.1.

Batch Operation: An operational process that is carried out using a fixed amount of material and terminates when this is used up.

3.2.

Chemical Etching: The formation of characteristic features on metal or glass surfaces after exposure to a chemical reagent.

3.3.

Continuous Feed Operation: An operational process that is continuously supplied with material and only terminates when the operator stops the supply of this material.

3.4.

Evaporating / Florentine Flask: The flask that contains the liquid to be evaporated and is continually rotated to increase the surface area of the liquid surface.

3.5.

Implosion: The inward collapse of a highly evacuated glass vessel.

3.6.

Receiving Flask: A round bottomed flask in which the distillate collects in.

3.7.

Rotary Evaporator: A distillation unit that incorporates a condenser with a rotary flask system that rotates to continually transfer a thin layer of liquid over the entire inner surface to increase the surface area for evaporation by heating.

4.

Responsibility

4.1.

The members of the Department of Pharmacy (staff and students) are responsible for following this SOP.

Page 2 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

4.2.

The designated Laboratory Officer or Laboratory Assistant is responsible for ensuring that this SOP is followed.

5.

Procedure

5.1.

Diagram of Bibby Sterilin

®

Rotary Evaporator RE-100

1. Stand

2. Drive Motor

3. Rotation Speed Control

4. Condenser

5. Rotating / Florentine Flask

6. Receiving Flask

7. Vapour Tube

8. Feed / Vacuum Release Adapter

9. Spherical Joint Clip

10. Conical Joint Clip

11. Vacuum Seal Assembly

(see SOP/PD/317_02/A1)

Page 3 of 17

12. Up/Down Lift Switch

13. Mains On Indicator

14. Manual Lift Clamp

15. Water Connections

16. Vacuum Line Connections

17. Motor Support Bracket

(see SOP/PD/317_02/A1)

18. Motor Support Rod

19. Condenser Reatining Cap and Spring

20. Glassware Angle Hand Clamp

21. Jack (see SOP/PD/317_02/A1)

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.2.

Installation

5.2.1.

Place the stand [ 1 ] on a level surface.

5.2.2.

Fit the motor bracket [ 17 ] to the top of the jack [ 21 ].

5.2.3.

Check that the fitting for the support rod is facing forward.

5.2.4.

Check that the bracket is angled downwards (see

SOP/PD/317_02/A1 fig1).

5.2.5.

Tigthen the allen screws with an allen key.

5.2.6.

Place the support rod [ 18 ] into its fitting.

5.2.7.

Tigthen the accompanying allen screw.

5.2.8.

Check that the end of the screw locates in the recess of the rod

(see SOP/PD/317_02/A1 fig 1).

5.2.9.

Place the motor assembly [ 2 ] onto the support rod [ 18 ].

5.2.10.

Tighten the hand clamp [ 4 ] to fix the motor assembly in position.

5.2.11.

Check that the speed control [ 3 ] is facing foward.

5.2.12.

Check that the clamp is located on the flat side of the rod.

5.2.13.

Check that the motor is located as low as possible on the support rod.

5.2.14.

Plug the electrical connection of the motor into the socket at the rear end of the stand.

5.2.15.

Pass the plain end of the vapour tube [ 7 ] through the motor assembly.

5.2.16.

Push this vapour tube firmly into position until it locates firmly behind the spring clip.

5.2.17.

Check that the conical joint is on the right of the motor when viewed from the front (see SOP/PD/317_02/A1 fig 2).

5.2.18.

Place the defender, main vacuum seal and subseal onto the vapour tube.

5.2.19.

Slide these components of the vacuum seal down until they locate in the bearing housing (see SOP/PD/317_02/A1 fig 2).

5.2.20.

Check that all 3 elements of the vacuum seal are fitted in the correct sequence (see SOP/PD/317_02/A1 fig 2).

5.2.21.

Check that the spring loaded slide of the main seal is facing the bearing housing (see SOP/PD/317_02/A1 fig 2).

5.2.22.

Place the retaining cap [ 19 ] over the wide end of the condenser with the screw thread facing outwards.

5.2.23.

Retain cap in position with the circular spring (see

SOP/PD/317_02/A1 fig 3).

5.2.24.

Place the condenser over the vapour tube so that the wide end of the condenser squeezes up to the vacuum seal.

Page 4 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.2.25.

Check that the spherical joint is pointing downwards.

5.2.26.

Screw the retaining cap onto the bearing housing to secure tightly.

5.2.27.

To set the condenser to the required angle:

5.2.27.1.

Support condenser while loosening the hand clamp

[ 20 ].

5.2.27.2.

Position the condenser at the required angle.

5.2.27.3.

Hold it in place while re-tightening the hand clamp.

5.2.28.

Hold the receiving flask [ 6 ] in position and secure using the spherical joint clip [ 9 ].

5.2.29.

Place the rotating flask [ 5 ] onto the end of the vapour tube and secure using the conical joint clip [ 10 ].

5.2.30.

Remove plastic safety connectors from the condenser and fit into the hose.

5.2.31.

Secure the hose using a Jubilee clip.

5.2.32.

Fit the connectors and the hose to the water inlet and outlet connections on the condenser respectively (see

SOP/PD/317_02/A1 fig 4).

5.2.33.

Remove the grey plastic screwcap that is attaching the feed vacuum release adapter to the condenser.

5.2.34.

Assemble the screw cap onto the feed/vacuum release adapter

(see SOP/PD/317_02/A1 fig 5).

5.2.35.

Pass the tube that is attached to the feed/vacuum release adapter through the condenser and vapour tube.

5.2.36.

Check that the end of this tube is inside the rotating flask.

5.2.37.

Tigthen the grey screwcap onto the screw thread of the condenser.

5.3.

Operation

5.3.1.

Batch Operation

5.3.1.1.

Remove the rotating flask [ 5 ] from the vapour tube

[ 7 ].

5.3.1.2.

Fill the rotating flask with the liquid to be evaporated ensuring that it is not more than half full.

5.3.1.3.

Check that both the stop cock and vacuum release screwcaps are closed.

Page 5 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.3.1.4.

Check that water is flowing through the condenser at approximately 60L/hr.

5.3.1.5.

Check that the speed control [ 3 ] is set to 0.

5.3.1.6.

Switch on the electricity supply. The green “ mains on indicator ” will light up.

5.3.1.7.

Press and hold the [ UP ] switch until the glassware stops moving to raise the glassware assembly to the highest position.

5.3.1.8.

Place a suitable water bath directly below the rotating flask.

5.3.1.9.

Press and Hold the [ DOWN ] switch until the rotating flask is partially immersed in the water of the water bath.

5.3.1.10.

Set the speed control [ 3 ] to the required setting. A yellow lamp will light up on the speed control.

5.3.1.11.

Attach a vacuum line to the side arm of the condenser [ 16 ] if evaporation at reduced pressure is desired.

5.3.1.12.

Set the temperature of the water bath to the desired temperature.

5.3.1.13.

Wait for the evaporation process to be complete.

5.3.1.14.

Unscrew the vacuum release screwcap.

5.3.1.15.

Set the rotation speed control to 0.

5.3.1.16.

Press and hold the [ UP ] switch to raise the glassware out of the water bath.

5.3.2.

Continuous Feed Operation

5.3.2.1.

Attach a length of flexible tubing to the sidearm of the feed/vacuum release adaptor [ 8 ].

5.3.2.2.

Repeat steps 5.3.1.3 to 5.3.1.9.

5.3.2.3.

Immerse the free end of the flexible tubing into the container holding the liquid to be evaporated.

5.3.2.4.

Attach a vacuum line to the side-arm of the condenser [ 16 ].

5.3.2.5.

Slowly open the stopcock on the feed/vacuum release adapter [ 8 ] to draw liquid into the rotating flask by the created vacuum.

5.3.2.6.

Close the stopcock when sufficient liquid has entered the flask.

Page 6 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.3.2.7.

Set the speed control [ 3 ] to the required setting. A yellow lamp will light up on the speed control.

5.3.2.8.

Set the temperature of the water bath to the desired temperature.

5.3.2.9.

Re-open the stopcock when further quantities of liquid will need to be added during the evaporation.

5.3.2.10.

If receiving flask requires emptying during the operation:

5.3.2.10.1.

Raise glassware out of the water bath.

5.3.2.10.2.

Wait until boiling ceases and distillate

stops dripping into the receiver flask.

5.3.2.10.3.

Stop rotation and release the vacuum.

5.3.2.10.4.

Remove the receiving flask.

5.3.2.10.5.

Empty the receiving flask.

5.3.2.10.6.

Re-attach the receiving flask.

5.3.2.10.7.

Lower the glassware into water bath.

5.3.2.10.8.

Set the speed control to the required

Setting to continue the process.

5.3.2.11.

Repeat steps 5.3.1.14 to 5.3.1.16 when evaporation process is complete.

5.4.

Maintenance

5.4.1.

Isolate unit from the mains electricity, water and vacuum supplies before commencing with any maintenance procedures.

5.4.2.

Wash the vacuum seal with distilled water and allow to dry naturally.

5.4.3.

Clean all glassware with distilled water and examine for scratches, cracks and signs of chemical etching.

5.4.4.

Replace any damaged parts before further use.

5.4.5.

Clean the main stand and the motor with a mild cleaning agent.

Page 7 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

5.5.

Troubleshooting

Fault Cause/s

Faulty vacuum pump

Vacuum seal inserted wrong

Poor Vacuum way round

Dirty vacuum seal

Worn vacuum seal

Loose condenser screw cap

Dirty Quickfit joints

Scratched Quickfit joints

Loose vacuum connection

-

Split „O‟ ring vacuum connector

Check that stopcock and vacuum release screwcap are closed

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

Solution/s

Check vacuum pump

Arrange accordingly

Remove and clean

Replace

Check and fasten tightly

Clean

Check and replace

Check and tighten

Check and replace

Noisy Operation

Inoperative drive motor

N/A

N/A

N/A

Remove vapour tube and apply vacuum grease to the inner ground surface

Check plug fuse and the fuses in the rear of the stand

Check fuse in plug and the fuses in the rear of the stand

Inoperative lift

Page 8 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.6.

Flow Charts

5.6.1.

Installation

Start

Place stand [ 1 ] on level surface

Fit motor bracket [ 17 ] to top of jacket [ 21 ]

Check that fitting for support rod is facing downwards

Check that bracket is angled downwards

Tighten allen screws with allen key

Place support rod [ 18 ] into its fittings

Check that end of screw locates in recess of rod

Place motor assembly [ 2 ] onto support rod [ 18 ]

Tighten hand clamp [ 4 ]

to fix motor in position

Check that speed control [ 3 ]

is facing forwards

Check that clamp is located on flat side of rod

Check that motor is located as low as possible on support rod

Plug electrical connection of motor into socket at rear end of stand

1

Page 9 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

1

Pass plain end of vapour tube [ 7 ]

through motor assembly

Push vapour tube firmly into position until it locates firmly behind spring clip

Check that conical joint is on the right of motor when viewed from front

Place defender, main vacuum seal and subseal onto vapour tube

Slide these components down until they locate in bearing housing

Check that all 3 components are fitted in the correct sequence

Check that spring loaded slide of main seal is facing the bearing housing

Place retaining cap [ 19 ] over wide end of condenser with screw thread facing outwards

Retain cap in position with circular spring

Place condenser over vapour tube so that wide end of condenser squeezes up to vacuum seal

Check that spherical joint is pointing downwards

Screw retaining cap onto bearing

housing to secure tightly

Need to set condenser to a required angle

No

Yes

2

3

Page 10 of 17

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

3

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

2

Support condenser while loosening hand clamp [ 20 ]

Position condenser at required angle

Hold in place while re-tightening hand clamp

Hold receiving flask [ 6 ] in position and secure using spherical joint clip [ 9 ]

Place rotating flask [ 5 ] onto end of vapour tube and secure using conical joint clip [ 10 ]

Remove plastic safety connectors from condenser and fit into the hose

Secure hose using Jubilee clip

Fit connectors and hose to water inlet and outlet connections on the condenser

Remove grey plastic screw cap that is connecting the feed vacuum release adapter to the condenser

Assemble screw cap onto feed/vacuum release adapter

Pass tube that is attached to

feed/vacuum release adapter through condenser and vapour tube

Check that end of tube is inside rotating flask

Tighten grey screw cap onto screw thread of condenser

End

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

Page 11 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

Ref. No.

SOP/PD/317_02

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Yes

5.6.2.

Operation

Start

Perform batch operation

Remove rotating flask [ 5 ] from vapour tube [ 7 ]

Fill rotating flask ensuring

that it is not > half full

No

Perform continuous feed operation

Attach a length of flexible tubing to sidearm of feed/vacuum release adapter [ 8 ]

Check that both stop cock and vacuum release screwcaps are closed

Valid for:

2 years from approval

1

Check that both stop cock and vacuum release screwcaps are closed

Check that water is flowing through condenser at approx 60L/hr

Check that speed control [ 3 ] is set to 0

Switch on electricity supply

Press and hold [ UP ] switch until glassware stops moving

Place a suitable water bath directly below rotating flask

Press and hold [ DOWN ] switch until rotating flask is partially immersed in water bath

Set speed control [ 3 ] to required setting

Evaporation at reduced pressure is desired

Yes

No

3

Check that water is flowing through condenser at approx 60L/hr

Check that speed control [ 3 ] is set to 0

Switch on electricity supply

Press and hold [ UP ] switch until glassware stops moving

Place a suitable water bath directly below rotating flask

Press and hold [ DOWN ] switch until rotating flask is partially immersed in water bath

Immerse free end of flexible tubing into container holding liquid to be evaporated

Attach vacuum line to side-arm of condenser [ 16 ]

Slowly open stopcock on feed/vacuum release adapter [ 8 ] to draw liquid into the rotating flask

4

2

Page 12 of 17

3

5

1

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

2

Attach vacuum line to the side arm of condenser [ 16 ]

Set T of water bath to the desired T

Unscrew vacuum release screwcap when evaporation is complete

Set rotation speed control [ 3 ] to 0

Press and hold [ UP ] switch to raise glassware out of water bath

End

4

Close stopcock when sufficient

liquid has entered the flask

Set speed control [ 3 ] to desired setting

Set T of water bath to the desired T

Re-open stopcock when further quantities of liquid need to be added

Receiving flask requires emptying

Yes

Raise glassware out of water bath

No

5

Wait until boiling ceases and distillate stops dripping into receiver flask

Stop rotation and release vacuum

Remove receiving flask

Empty receiving flask

Re-attach receiving flask

Lower glassware into water bath

Set speed control to required setting to continue the process

Page 13 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

5.6.3.

Maintenance

Start

Isolate unit from mains electricity, water and vacuum supplies before commencing with any maintenance procedures

No

Vacuum seal needs cleaning

Yes

Wash with distilled water and allow to dry naturally

Glassware needs cleaning

Yes

Clean with distilled water and examine for scratches, cracks and signs of chemical etching

No

No

Any damaged parts

Yes

Replace before further use

Main stand and/or motor needs cleaning

Yes

Clean using a mild cleaning agent

No

End

Page 14 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

6.

Precautions

6.1.

Examine all glassware for any signs of scratches or chemical etching before operating the apparatus under vacuum due to the risk of implosion.

6.2.

Take special care when using the evaporator with flammable solvents.

6.3.

Never fill the rotating flask by more than half of its capacity i.e. approximately 500ml.

6.4.

When lowering the glassware into the water bath, ensure that the glassware does not make contact with any part of the bath and that the water does not overflow as the flask is immersed.

6.5.

When setting the desired speed of rotation, ensure that the rotation is not so fast that the water is splashed out of the bath.

6.6.

In the event of a power failure, the glassware may be raised manually in the following manner:

6.6.1.

Disconnect from the electricity supply.

6.6.2.

Set the speed control to 0.

6.6.3.

Loosen the hand clamp [ 14 ].

6.6.4.

Lift the drive motor and glassware assembly up the support rod

[ 19 ].

6.6.5.

Tighten the hand clamp [ 14 ].

6.6.6.

Re-position accordingly to the normal operating position at the bottom of the support rod before further use.

6.7.

Ensure that no strain is applied to the feed/vacuum release adapter during a continuous feed operation.

6.8.

Ensure that, each time liquid is added to the rotating flask during a continuous feed operation, there is sufficient capacity in it to cope with this addition.

6.9.

Any servicing or repair should only be undertaken by suitably qualified personnel.

7.

References

Bibby Sterilin. Rotary Evaporator RE-100 Assembly and Operating

Instructions.

8.

Appendices

SOP/PD/317_02/A1 – Accompanying Installation Diagrams

Page 15 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

Ref. No.

SOP/PD/317_02

Valid for:

2 years from approval

9.

Revision History

Version Number

01

02

Amendments/ Reasons for change

Initial Release

Inclusion of subheading titles of

Procedure section in Table of Contents

Update of entire SOP to Version 2

Page 16 of 17

UNIVERSITY OF MALTA

FACULTY OF MEDICINE & SURGERY

PHARMACY DEPARTMENT

STANDARD OPERATING PROCEDURE

Ref. No.

SOP/PD/317_02

BIBBY STERILIN

®

RE-100

ROTARY EVAPORATOR

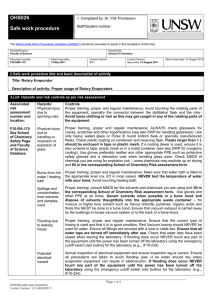

Figure 3

SOP/PD/317_02/A1 – Accompanying Installation Diagrams

Figure 1

Figure 2

Figure 5

Valid for:

2 years from approval

Figure 4

Page 17 of 17