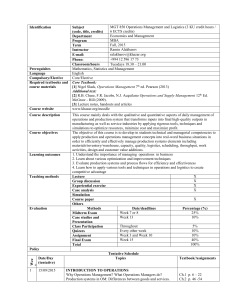

11

Supply Chain

Management and

Logistics

McGraw-Hill/Irwin

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved.

Agenda

Supply Chain Management (SCM)

Supply Chain Logistics

11-2

Supply Chain Management

Supply chain management: An integrated

philosophy to manage the multidirectional flow

of materials and information through an entire

channel, from the first raw material supplier to

the ultimate user of the finished product.

11-3

Objectives of SCM

Optimizing coordination in operations and

requirements

Minimizing duplication and non-valueadding activities

Reducing costs while maintaining superior

quality and customer service

Reducing inventory

Reducing cycle times

11-4

New Key Terms in SCM

Value Proposition: a clear concise set of factual

statements describing the real value (benefits)

customers can expect to receive from a firm’s

products and services. A good value

proposition quantitatively differentiates the

firm’s offerings from those of competitors, (e.g.,

40-50% material savings).

Value Chain: an analysis process that

disaggregates the channel system into each

channel member’s activities and specifically

considers how each activity creates value for

the channel’s ultimate customers.

11-5

New Key Terms in SCM

Value Added: traditionally referred to how much

margin a particular product could earn for a firm.

High value added products were preferred over

low value added products. Recently the phrase is

also used to refer to how much value a channel

member brings to a particular product’s supply

chain.

11-6

Supply Chain Logistics

Traditionally the management of material

flow inbound, through, and outbound from

a particular firm. The sum of the channel

members supply chain logistics are

coordinated on a channel wide scale by

Supply Chain Management.

11-7

Logistics Management

Logistics involves more than physical distribution. In the

science of logistics, the flow of materials is efficiently

managed inbound-through and outbound of an

organization.

Two primary product flows:

• Materials management (physical supply): Flows that

provide raw materials, components, and supplies to

the production process.

• Physical distribution management: Flows that deliver

the completed product to customers and channel

intermediaries.

11-8

The Materials Management

Concept

Usually one manager responsible for

planning, organizing, motivating, and

controlling all the activities principally

concerned with the flow of materials into

an organization.

View material flow as a system.

11-9

The Materials Management

Concept

Approaches to Materials Management

• Traditional Approach

• Just-in-Time (JIT) Approach

• Integrated Supply Strategies

Reasons for Adopting the Materials

Management Concept

• Improved communication and coordination

between departments

Can balance conflicting interests

Faster, smoother material flow

Lower inventory and logistics costs

11-10

Just-In-Time Systems

JIT = Just-In-Time

Adopted and implemented by many original

equipment manufacturers (OEMs) and

suppliers of component parts and materials.

An operational philosophy thought to epitomize

the relationship marketing model.

Uses a “pull” approach; much more than

material arriving just in time.

11-11

JIT Features

Zero defects—Strict quality control

Frequent, reliable delivery of quantities as needed

Close location

Advanced telecommunications, EDI.

Single sourcing—Customer-supplier

partnerships/alliances

Value analysis

Early supplier involvement

Evergreen contracts

Customer access to financial and process

information

11-12

Integrated JIT versus

U.S. Manufacturing (pre-1985)

JIT System

Pre-1985 U.S. Mfg.

What it is

An integrated

philosophy of

operating a

business

The way it has

always been done

Raw material and

in-process inventory

A liability to be

eliminated

Protection against

problems, necessary

to maximize

machine utilization

Order size

Immediate needs

only

Based on EOQ and

efficient long

production runs.

11-13

Integrated JIT vs.

U.S. Manufacturing (pre-1985)

JIT System

Pre-1985 U.S. Mfg.

Production setup time

Fast at insignificant

cost; flexible

manufacturing

(Ex: stamping die

change =5 minutes)

Low-priority concern

(Ex: same die change

=5 hours)

Suppliers

Part of the teamsingle source

Adversary-multiple

source

Delivery

Must arrive within

small time window,

go right to the line,

packaged for

assembly efficiency

Arrives on due date

plus or minus,

packaged for

warehouse storage

11-14

Integrated JIT vs.

U.S. Manufacturing (pre-1985)

JIT System

Pre-1985 U.S. Mfg.

Purchasing

Involve supplier in

design; long-term

contracts at fixed

prices

Design in secret,

competitive bidding;

contract for current

requirement; recognize

need for price increases

Efficiency

improvements

Workers see as

strengthening

company

Workers see as threat

Production control and

scheduling

Demand “pull”—

Kanban to minimize

in-process inventory

Forecast “push”—

maximize machine

utilization

11-15

MRP Systems

MRP = Materials Requirement Planning

MRP systems: Large computer systems used to plan

and schedule operations using a “push” approach.

Starting from the order due dates and forecast, MRP

considers every required raw material, operating

supply, and component part, their order of use, and

what equipment they will occupy.

Backs into a schedule of what will have to be done

when, including what will have to be ordered when

and received when.

11-16

Physical Distribution (outbound material flow)

Physical distribution: The process of planning, implementing, and

controlling efficient, effective flow and storage of goods, services,

and related information from point of origin to point of consumption

for the purpose of conforming to customer's requirements.

Why is it important to learn about physical distribution?

Physical distribution cost can represent 20% or more of the

selling price of a product.

It is an integrated part of the entire company system—problems in

other areas impact distribution and vice versa.

From customer’s perspective, the supplier’s physical distribution

function gets the right products to them, at the right place, at the

right time. These are basic customer rights (along with right price

and right condition).

11-17

Materials

management

Supplier

Physical distribution

management

Manufacturer

Customer

Logistics Management

11-18

Supply chain management

(a series of connected logistics flows)

Logistics management

Materials management

Incoming transportation

Receiving

Purchasing

Incoming warehousing

Inventory control

Physical distribution

Traffic management

Shipping

Customer service

Finished goods

11-19

Functions of Traffic Management

Mode and carrier selection

Routing

Claims processing

Operation of private (company-owned)

transportation

11-20

Many of the imported goods you purchase

were shipped in 20-foot or 40-foot

steel containers

11-21

Large cranes loaded the containers on a ship.

(Image courtesy of the Port of Charleston)

11-22

Larger container ships can hold

4,000 to 6,000 containers.

(Image courtesy of Maersk Sealand)

11-23

After unloading from the ship, the containers can

be loaded onto a flatbed rail car for additional

intermodal shipping.

(Image courtesy of CSX

Corp.)

11-24

Alternatively, a container can be attached to

a set of wheels for motor transport

(as an 18-wheeler trailer).

11-25

Intermodal container motor carrier

(Image courtesy of Maersk Sealand)

11-26

Rail freight carrier

Barge/river freight carrier

(Image courtesy of CSX Corp.)

11-27

Air freight carrier

Pipeline

Container stack train

Jumbo jet air freight

11-28

Major Advantages by Transportation Mode

Motor

• Speed of

delivery

• Diversity of

equipment

• Flexibility

• Frequency of

movement

• Transfer of

goods to other

carriers

• Convenient to

both shipper

and receiver

Rail

• Mass movement of

goods

• Low unit cost of

movement

• Dependability

• Long-haul moving

• Wide coverage to major

markets and suppliers

• Many auxiliary services

(i.e., switching)

• Transfer of goods to

other carriers

• Specialized equipment

Water

• Very low unit

cost of

movement

• Movement of

low-unit-value

commodities

• Long-haul

movement

• Mass

movement of

bulk

commodities

(continued) 11-29

Major Advantages by Transportation Mode

Pipeline

•Lowest unit cost

of movement

•Mass

movement

of liquid or gas

products

•Long-haul

moving

•Large capacity

•Most

dependable

mode

Air

•Frequent service to

major markets

•Large capability

•Overnight service

•Most rapid speed

of any carrier

Intermodal

•Cost savings

•Lower loss and

damage claims

due to

containerization

•Service extended

to more shippers

and receivers

•Reduced

handling and

storage costs

11-30

Controllable Elements in a Logistics System

Customer service

Logistics communications

Warehousing

Packaging

Production planning

Order processing

Transportation

Inventory control

Materials Handling

Plant and warehouse location

11-31

Major Categories of Service Complaints

Traffic and transportation

• Damaged merchandise

• Carrier did not meet

standard transit time

• Merchandise delivered

prior to date promised

• Carrier failed to follow

customer routing

• Carrier did not comply

with specific instructions

• Errors present on bill of lading

• Condition or type of transport

equipment not satisfactory

Warehousing and packaging

• Merchandise delivered late

• Problem with containers in

packaging plants

• Special promotion merchandise

not specified in delivery

• Errors in warehouse release

forms

• Incorrect types and quantities of

merchandise shipped

• Papers not mailed promptly to

headquarters

• Field warehouse delivered

damaged merchandise

11-32

Major Categories of Service Complaints

Inventory control

• Stockouts

• Contaminated

products received

• Product

identification errors

• Poor merchandise

shipped

Sales order service

• Delayed shipments

• Invoice, sales coding,

or brokerage errors

• Special instructions

ignored

• No notification of

late shipments

11-33

11-4

11-34