Chapter 14 - notes

advertisement

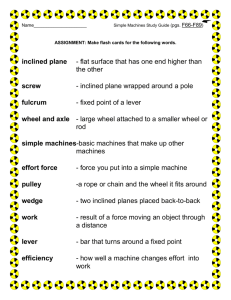

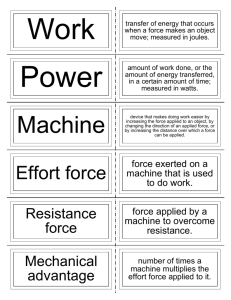

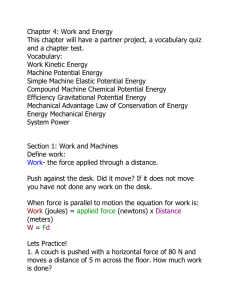

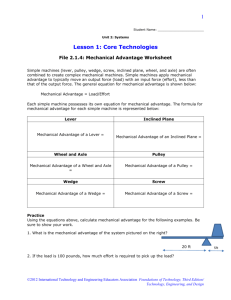

Work, Power, and Machines Chapter 14 Work & Power Section 14-1 Work Work – the product of force and distance Work = Force x Distance For a force to do work on an object, some of the force must act in the same direction as the object moves. If there is no movement, no work is done. Any part of a force that does not act in the direction of motion does no work on an object. Joules A joule is the SI unit for work When a force of 1 newton moves an object 1 meter in the direction of the force, 1 joule of work is done. Calculating Work Your family is moving to a new house. While you lift a box straight up 1.5 meters to put it on the moving truck, you exert an upward force of 200 N. How much work was done? Work = Force x Distance Work = 200 N x 1.5 meters = 300 N·m Work = 300 Joules Power Doing work at a faster rate requires more power. To increase power, you can increase the amount of work done in a given time, or you can do a given amount of work in less time. The SI unit for power is the watt. (Joules/sec) Work Power = Time Horsepower – one horsepower is equal to about 746 watts Calculating Power If it took you exactly 1 second to lift the box into the moving truck from the last problem, how much power was required? Power = work/time Power = 200 N x 1.5 m /1 sec Power = 300 Joules/1 sec Power = 300 Joules/sec Power = 300 Watts Try one… You lift a book from the floor to a bookshelf 1.0 m above the ground. How much power is used if the upward force is 15.0 N and you do the work in 2.0 seconds? Power = Work/Time Power = (15.0 N x 1.0 m)/ 2.0 sec Power = 15.0 Joules/2.0 sec Power = 7.5 Watts Work & Machines Section 14-2 Machines Do Work Machines make work easier to do. They change the size of a force needed, the direction of a force, or the distance over which a force acts. Because of friction, the work done by a machine is always less than the work done on the machine. Work Input to a Machine Input force – the force you exert on a machine. Input distance –the distance the input force acts through Work input – the work done by the input force acting through the input distance Work Output of a Machine Output force – the force that is exerted by a machine Output distance the distance the output force is exerted through Work output – Output force x Output distance Mechanical Advantage and Efficiency Section 14-3 Mechanical Advantage Mechanical advantage is the number of times that the machine increases an input force. Actual mechanical advantage – the ratio of the output force to the input force Actual mechanical advantage = Output Force Input Force Try one… You test a machine and find that it exerts a force of 5N for each 1 N of force you exert operating the machine. What is the actual mechanical advantage? Actual mechanical advantage = AMA = 5 N ÷ 1 N AMA = 5 Output Force Input Force Ideal Mechanical Advantage IMA – the mechanical advantage in the absence of friction Because friction is always present, the actual mechanical advantage of a machine is always less than the ideal mechanical advantage. Input distance Ideal mechanical advantage = Output distance Try one… A woman drives her car up onto wheel ramps to perform some repairs. I she drives a distance of 1.8 meters along the ramp to raise the care 0.3 meter, what is the ideal mechanical advantage of the wheel ramp? Input distance IMA = Output distance IMA = 1.8 meters ÷ 0.3 meters IMA = 6 Efficiency The percentage of the work input that becomes work output Because there is always some friction, the efficiency of any machine is always less than 100 percent. Work output Efficiency = Work input x 100% Try one… You have just designed a machine that uses 1000 J of work from a motor for every 800 J of useful work the machine supplies. What is the efficiency of the machine. Work output Efficiency = Work input x 100% Efficiency = (800 J ÷ 1000 J) x 100% Efficiency = 0.80 x 100% Efficiency = 80% Simple Machines Section 14-4 Simple Machines The six types of simple machines are the lever, the wheel and axle the inclined plane, the wedge, the screw, and the pulley. Levers A rigid bar that is free to move around a fixed point. Fulcrum - the fixed point the bar rotates around Input arm – the distance between the input force and the fulcrum Output arm – the distance between the output force and the fulcrum Levers To calculate the ideal mechanical advantage of any lever, divide the input arm by the output arm. First class- screwdriver used to open a paint can Second class – wheelbarrow Third class - broom Wheel and Axle Consists of two disks or cylinders, each one with a different radius To calculate the ideal mechanical advantage of the wheel and axle, divide the radius (or diameter) where the input force is exerted by the radius (or diameter) where the output force is exerted. Inclined Planes A slanted surface along which a force moves an object to a different elevation. The ideal mechanical advantage of an inclined plane is the distance along the inclined plane divided by its change in height. Wedges A V-shaped object whose sides are two inclined planes sloped toward each other A thin wedge of a given length has a greater ideal mechanical advantage than a thick wedge of the same length Screws An inclined plane wrapped around a cylinder Screws with threads that are closer together have a greater ideal mechanical advantage. Pulleys A simple machine that consists of a rope that fits into a groove in a wheel. The ideal mechanical advantage of a pulley or pulley system is equal to the number of rope sections supporting the load being lifted. Three types – fixed pulley, movable pulley and pulley system Compound Machines Compound machine – a combination of two or more simple machines that operate together. Examples – car, washing machine, clock