Facility Planning: Capacity

advertisement

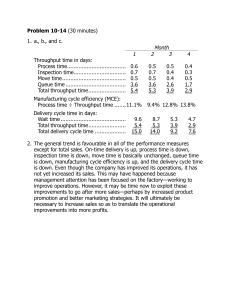

Facility Planning: Capacity Capacity Planning • Interrelated facility planning decisions: 1. 2. 3. 4. Number of facilities and general type Capacity Locations Layout • Facility design process dependent upon objective(s) Strategic Importance 1. Capital investment (machinery, technology, land, buildings, etc.) 2. Long-term commitment 3. Relationship between capacity and costs (operating efficiency) 4. Constrains the short and long-term rate of output Capacity Planning Decision Elements 1. Forecasting future capacity needs (amount and timing) 2. Estimating capacities of present facilities: Design, Effective (standard), Maximum practical capacity 3. Identifying and evaluating alternative sources 4. Selecting from among competing alternatives Measurements of Capacity 1. 2. 3. 4. 5. Aggregate unit Utilization = actual output/design capacity Efficiency = actual output/effective capacity Throughput time Process Velocity: similar to throughput time, but takes into account waste (wait, storage, transfer, inspect times); measured as throughput time/valueadded time 6. Productivity: how well a firms uses its resources; measured as output/input Estimating Capacity • Difficult, Why? long time horizon, changing economy, consumer preferences, technology, demographics, political events, new products, product obsolescence, competitor actions • Short-term, intermediate-term, long-term Capacity Planning Strategies • Demand leading, Lagging, Matching • Demand Management • Simultaneous capacity planning choices 1. Layout structure 2. Focus of facility 3. “Chunks” 4. Diseconomies of scale Analyzing Capacity Planning Decisions: Various Techniques 1. Cost-Volume-Profit (Breakeven Analysis) 2. Financial Analysis a. Payback b. Present Value c. Internal Rate of Return 3. Computer Simulation and Waiting Line Analysis 4. Linear Programming 5. Decision Tree Analysis