Full Paper Template

advertisement

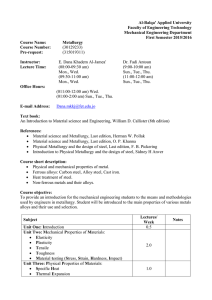

Effect of Carbon Content on Burring and Tapping in Ultra High Strength TRIP Sheet Steels Taro KOSEN and Hanako KOSEN Nagano National College of Technology Advanced course and Dept. of Mechanical Engineering 716 Tokuma, Nagano, Nagano 381-8550 Japan taro@nagano-nct.ac.jp Abstract— Effect of thermal drilling condition on burring of (0.1-0.4)C-1.5Si-1.5Mn (mass%) ultra high strength TRIPaided sheet steels with polygonal ferrite matrix (TDP steels) was investigated for automotive applications. The combined rotational and downward force of the thermal drilling tool bit created friction heat. The height of the bushing was roughly 3 to 4 times the initial sheet thickness. The bushings are ideal for thread applications, as the strength of threads was significantly increased. We found that the burring and tapping contributed to the improvement of the tensile strength of 980 MPa class TRIP steel. A flowdrill worked so well on burring of the TDP steels, and make it possible that nuts are not used. As for tapping of the following burring of TDP steel (thickness: 1.2 mm) using M6 short type flowdrill. Nutless became possible by machining center. Keywords— TRIP Sheet Steel; Burring; Tapping; Thermal Drilling I. percentage, and carbon was in the range of 0.1 to 0.4 mass%. Hereafter, these steels after heat treatment [2] are named TDP1 toTDP4. For comparison with TDP steel, the ferrite martensite dual-phase sheet steel (MDP steel) tempered at 400°C for 1 000 s that did not contain retained austenite (γ R ), as shown in Fig. 1(b), was also prepared. Tensile testing was performed on an Instron type of tensile testing machine at a crosshead speed of 1 mm/min (strain rate: 2.8×10-4/s), using JIS-13B type tensile specimens. Table 1. Chemical composition (mass%) of steels used. steel TDP1 TDP2 TDP3 TDP4 MDP C 0.10 0.20 0.29 0.40 0.14 Si 1.49 1.51 1.46 1.49 0.21 Mn 1.50 1.51 1.50 1.50 1.74 P 0.015 0.015 0.014 0.015 0.010 INTRODUCTION Increasingly, weight reduction for fuel efficiency due to environmental pressures, and the improvement of crash safety, to defend the driver are requirements in the car industry. As TRIP [1]-aided steels possess excellent press formability, a great deal of research has been undertaken attempting to apply these steels to member parts, seat rails and automotive underbody parts such as lower arms. Research on the improvement of warm forming [2] and microstructure control [3] on stretch-flangeability of sheet steel has been reported, however there have been few investigations of the effect of drilling condition on burring TRIP-aided sheet steel. [4] In this investigation, effect of thermal drilling condition on burring of ultra high strength TRIP-aided sheet steels with polygonal ferrite matrix (TDP steels) is studied. II. EXPERIMENTAL PROCEDURE Table 1 shows the chemical composition of cold-rolled sheet steels (thickness: 1.2 mm) used in this study, and Fig. 1 shows the heat treatment diagram. TRIP-aided sheet steel with polygonal ferrite matrix (TDP steel) austempered at 400°C for 1 000 s in salt bath after intercritical annealing at 780°C for 1 200 s, as shown in Fig. 1(a), were prepared. The TDP steels contained similar silicon and manganese Fig. 1. Heat treatment diagram S 0.0012 0.0011 0.0012 0.0012 0.0030 Burring test was performed by a machining center at cutting feedrate of F=10 mm/min and rotational speed of n=3500 rpm, using plate specimens (150×50 mm) and experimental apparatus in Fig. 2. A bushing was produced by flowdrill of M6 short type (diameter: D=5.3 mm). Burring and tapping tests were measured z-axis loading meter (S) corresponds to thrust and spindle loading meter (T) corresponds to torque, respectively. specimen flowdrill vise retained austenite (fγ0) increases and its carbon concentration (Cγ0) increases, as listed in Table 2. The relation between loading meter of burring and processing time (t) is shown in Fig. 4 (TDP2 steel, F=10 mm/min and n=3 500 rpm). Thrust (S) decreases with increasing the processing time of burring, but it becomes maximum thrust (Smax), and rises afterwards. Torque (T) becomes maximum torque (Tmax), and it decreases afterwards. We got a similar tendency in all specimens. The following tapping outside and the cutting model are shown in Fig. 5 (TDP2 steel, F=20mm/min, n=20 rpm). The relation between loading meters of tapping and processing time (t) are shown in Fig. 6(a) TDP2 and Fig. 6(b) TDP4. (F=20mm/min, n=20 rpm and M6×1). Thrust (S) of tapping is almost constant. Only Torque (T) becomes maximum torque (Tmax) as well as Fig. 4 and it decreases afterwards. We got a similar tendency in specimens except for TDP4 steel. TDP4 steel couldn’t conduct tapping and big torque was worked (Fig. 6(b)). When the flowdrill of M6 short type was used, the 50 mm (a) Fig. 2. Experimental apparatus for burring. The amount of retained austenite was quantified by X-ray diffractometry using Mo-Kα radiation. The initial volume fraction of retained austenite (f γ0 ) was quantified on the basis of the integrated intensity of (200)α, (211)α, (200)γ, (220)γ, and (311)γ diffraction peaks, termed the five-peak method. [5] The retained austenite lattice constant (aγ0) was measured from (220)γ diffraction peak using Cr-Kα radiation. Substituting the measured aγ0 value (nm) into the following equation, carbon concentration of the retained austenite (Cγ0, mass%) was calculated. [6] Cγ 0 (aγ 0 0.35467) / 4.67 103 (b) (1) Hardness was measured with the dynamic ultra microVickers hardness tester and was evaluated with a Vickers hardness (HV). III. RESULTS AND DISCUSSION Figure 3 shows scanning electron micrographs of the TDP2 steel (a), and that of the MDP steel (b). The metallurgical characteristics of these steels are listed in Table 2. From the micrographs, it is clear that a network-like second phase lies mainly on the polygonal ferrite (αf) grain boundaries in the TDP steels, similarly to the secondary microstructure in the MDP steel. And the second phase consists of the bainite (αb) islands and the retained austenite (γR) particles, near or apart from the bainite islands. Retained austenite characteristics and tensile properties of the steels are listed in Table 2. Tensile strength (TS) of the TDP steels is in a range of 651 to 1 103 MPa, which tends to increase with carbon content. Total elongation (TEl) of TDP steel is larger than that of MDP steel. With an increasing amount of carbon content of the steels, the volume fraction of Fig. 3. Scanning electron micrographs of (a) TDP2 and (b) MDP steels, in which “αf”, “αb” , “γR” and “αm” represent ferrite matrix, bainite island, retained austenite particle and martensite, respectively Table 2. Retained austenite characteristics and tensile properties of steels used. fγ0 Cγ0 TS×TEl YS TS TEl steel (mass%) (MPa) (MPa) (%) (GPa%) TDP1 0.049 1.31 429 651 37.2 24.2 TDP2 0.090 1.38 526 825 36.0 29.7 TDP3 0.132 1.41 562 895 32.2 28.8 TDP4 0.170 1.45 728 1103 32.8 36.2 MDP - - 593 783 13.1 10.3 fγ0: initial volume fraction of retained austenite, Cγ0: carbon concentration in retained austenite, YS: yield stress, TS: tensile strength, TEl: total elongation and TS×TEl: strength-ductility balance. T S S, T (%) 60 50 40 30 20 10 0 -10 Smax Tmax 0 10 20 30 40 t (s) 50 60 70 Fig. 4. Effect of time (t) on thrust (S) and torque (T) , in which Smax and Tmax represent maximum thrust and maximum torque, respectively (TDP2 steel, F=10 mm/min and n=3 500 rpm). 5 mm Fig. 5. Cut model after tapping (TDP2 steel, F=20 mm/min and n=20 rpm). 90 (a) 70 50 S T 30 max face, voids that occur in punching is not seen (Fig. 7(a)). At location of 0.3mm from the end face, large plastic flow can be observed. Figure 8 shows schematic diagram of cross-section, in which diamond represents indentation of Vickers hardness. Vickers hardness test (load: 0.98 N, holding time: 5 s) was conducted at 0.3 mm intervals from burring edge. Figure 9 shows the variation in Vickers hardness (HV) at burring section. HV of lower burring area indicates higher value than that of upper burring area. Therefore we can realize that work hardening has occurred. Also, comparing MDP steel with TDP1 to TDP4 steels, HV of the bushings in all measurement locations has been increased with the increase of carbon content. From this it seems that carbon content is a major impact on work hardening and strain-induced transformation. Figure 10 shows hardness increment (ΔHV=HVmax ―HV0) of TDP and MDP steels. We decided the initial hardness HV0 and the average of ⑨ to ⑫ HV is hardness on deforming (HVmax) after transformation. ΔHV became higher with increasing of carbon content in comparison from TDP1 to TDP4. We consider that it was affected great on straininduced transformation by increasing total carbon concentration (fγ0×Cγ0). It is the multiplication of initial carbon concentration (Cγ0) and initial volume fraction (fγ0) of γR by carbon content. In addition, comparing MDP steel with TDP steels, we found that ΔHV of TDP steel is relatively large. We consider that MDP steel generated work hardening by heat generation on burring, and TDP steel is affected strain-induced transformation. Figure 11 shows relation between Vickers hardness HV and total carbon concentration (fγ0×Cγ0). Comparing TDP1 to TDP4 steel, ΔHV became higher with increasing of carbon content (Fig. 11). T 90 (a) (b) 70 S 50 drilling S, T (%) 10 T max 30 T 10 -10 90 100 110 120 130 140 t (s) (b) Fig. 6. Effect of time (t) on thrust (S) and torque (T) ((a) TDP2 steel, (b) TDP4 steel, F=20 mm/min and n=20 rpm). tapping after burring made it possible, using machining center (MC). As a result, the steels of TDP1 to TDP3 made tapping possible. In changing amount of carbon adding in a range of 0.1 to 0.4 mass%, the influence in tapping was observed. Figure 7 shows the scanning micrographs of cross section of TDP2 steel after burring. Figure 7(a) is end face and Fig.7(b) is location of 0.3mm from the end face. Around end 5μm Fig. 7. Scanning electron micrograph after burring (TDP2 steel, (a) end face, (b) location of 0.3 mm from the end face). ΔHV 400 350 300 250 200 150 100 50 0 TDP1 TDP2 TDP3 TDP4 MDP steel Fig .10. Hardness increment (ΔHV) 700 600 Fig 8. Schematic diagram of cross-section. 700 (a) TDP1 500 300 100 0 0 200 (b) TDP2 600 500 TDP4 HV0 300 200 400 3 1 0.05 2 ⊿HV 0.1 0.15 0.2 0.25 fγ0×Cγ0 (mass%) 0.3 Fig 11. Relation between Vickers hardness (HV) and total carbon concentration ( fγ0×Cγ0) 400 IV. 300 SUMMARY 300 1) The flowdrill worked so well on burring of the TRIPaided sheet steels with polygonal ferrite matrix (TDP steels). As for tapping of the following burring of TDP steels (thickness: 1.2 mm) using M6 short type flowdrill, the burring became possible by machining center. 2) (0.1-0.3)C-1.5Si-1.5Mn (mass%) TDP steels (TDP1 to TDP3 steels) made tapping possible. 0.4C-1.5Si-1.5Mn (mass%) steel (TDP4 steel) was impossible of tapping. 200 REFERENCE 200 600 HV HVmax 500 400 HV 600 (c) TDP3 500 400 600 (d) TDP4 [1] 500 [2] 400 [3] 300 [4] 200 600 [5] [6] 13. (e) MDP 500 V. F. Zackay, E. R. Parker, D. Fahr and R. Busch: Trans. Am. Soc. Met., 60 (1967), p. 252. K. Sugimoto, A. Nagasaka, M. Kobayashi and S. Hashimoto: ISIJ International, 39 (1999), p. 56. A. Nagasaka, Y. Kubota, K. Sugimoto, A. Mio, T. Hojo, K. Makii, M. Kawajiri and M. Kitayama: ISIJ International, 50 (2010), p. 1441. A. Nagasaka, S. Hasebe, T. Matsushima, K. Sugimoto and T. Murakami: Journal of Iron Steel Research, International, 18 (2011), p. 442. H.Maruyama: J. Jpn. Soc. Heat Treat., 17 (1977), p. 198. Z. Nishiyama: Martensite Transformation, Maruzen, Tokyo, (1979), p. Authors Photo 400 Photo Photo Photo Hanako KOSEN Ziro KOSEN Saburo KOSEN 300 200 1 2 3 4 5 6 7 8 9 10 11 12 No. Fig. 9. Variation in Vickers hardness (HV) at burring section. Taro KOSEN