Plain Carbon Steels: Properties, Uses, and Microstructures

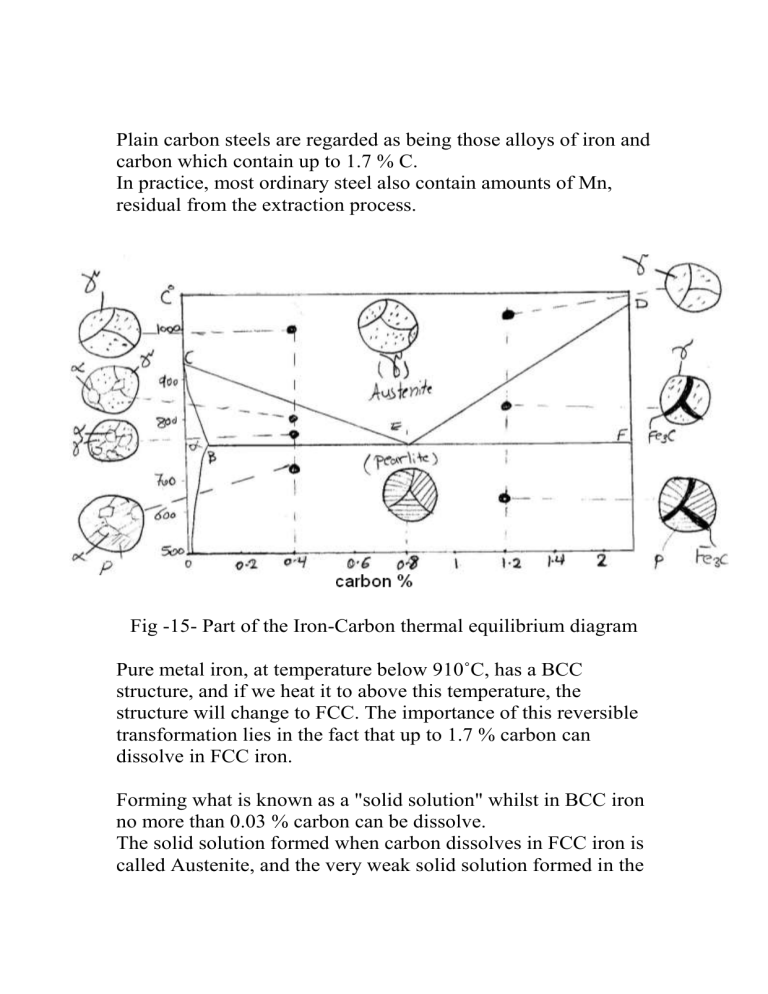

Plain carbon steels are regarded as being those alloys of iron and carbon which contain up to 1.7 % C.

In practice, most ordinary steel also contain amounts of Mn, residual from the extraction process.

Fig -15- Part of the Iron-Carbon thermal equilibrium diagram

Pure metal iron, at temperature below 910˚C, has a BCC structure, and if we heat it to above this temperature, the structure will change to FCC. The importance of this reversible transformation lies in the fact that up to 1.7 % carbon can dissolve in FCC iron.

Forming what is known as a "solid solution" whilst in BCC iron no more than 0.03 % carbon can be dissolve.

The solid solution formed when carbon dissolves in FCC iron is called Austenite, and the very weak solid solution formed in the

BCC structure is called Ferrite. For most practical purposes we can regard ferrite as having the same properties as pure iron.

When carbon is precipitated from austenite it is not in the form of elemental carbon (graphite), but as the compound iron carbide, Fe

3

C, usually called Cementite. This substance is very hard, as the amount of carbon increases, the hardness of the steel will also increase.

Transformation will begin at the appropriate upper critical temperature (CE) and end at the lower critical temperature of

7232. The relative amount of ferrite and pearlite will depend upon the carbon content of steel, but in every case ferrite will be almost pure iron and the pearlite will contain exactly 0.83 % carbon so far we have been dealing only with structure in plain carbon steel by cooling them slowly from an austenite condition.

By very rapid cooling from the austenite condition, such as would be obtained by water quenching, another structure called

Martensite is produced. This does not appear on equilibrium diagram because it is not equilibrium structure.. Rapid cooling has prevented structural equilibrium from being reach.

Martensite is very hard and brittle, and the steel is used in this condition only when extreme hardness is required.

The uses of plain carbon steels

The hardness of plain carbon steel increases progressively with increase in carbon content, so that generally the low-and medium carbon steel are used for constructional work, whilst the high carbon steels are used for the manufacture of tools and other components where hardness and wear-resistance are necessary. Typical uses of steels of various carbon content are shown below in table -1-

Type of Steel % Carbon Uses

Dead Mild 0.05 – 0.15

Wires

Mild 0.1 – 0.2

0.2 – 0.3

Structural Steels

Gears

Medium Carbon

High Carbon

0.3 – 0.4

0.4 – 0.5

0.5 – 0.6

0.6 – 0.7

0.7 – 0.8

0.8 – 0.9

Connecting Rods Crank

Shafts

Laminated Springs

Screw Drivers Hammers

Punches

Tool Steels 0.9 – 1

1 – 1.1

1.1 – 1.2

1.2 – 1.3

1.3 – 1.4

Springs

Drills

Ball Bearing

Knives

Saws

General Properties of Plain Carbon Steel

Generally, with an increase in the carbon content from 0.01

– 1.5 % in the alloy, its strength and hardness increases but still such an increase beyond 1.5 % causes appreciable reduction in the ductility and malleability of the steel.

See (Fig. 16) which explain the relationship between mechanical properties and carbon content.

Fig -16- Relationship between mechanical properties and carbon content

From Fig -16- we see that tensile strength increased with the increase of carbon content till (0.8 % C) pearlit 100 %, and this increase doesn't continue because cementite appears in the structure of plain carbon steel.

Types of plain Carbon Steel

* Low carbon steel or mild steel containing carbon up to 0.3 % responds to heat treatment as improvement in the ductility is concerned but has no effect in respect of its strength properties.

* Medium carbon steels, having carbon content ranging from

0.25 to 0.7 % improves in the machinability by heat treatment. It must also be noted that this steel is especially adaptable for machining or forging and where surface hardness is desirable.

* High carbon steels, is steel containing carbon ranging from 0.7

– 1.5 and is especially classed as high carbon steel. In the fully heat treated condition it is very hard and it will withstand high shear and wear.