Gas Turbine & Jet Propulsion: Brayton Cycle Case Study

advertisement

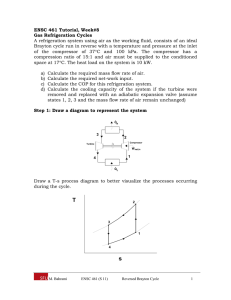

Gas Power Cycle - Jet Propulsion Technology, A Case Study Ideal Brayton Cycle (YAC 7-7) An closed ideal Brayton Cycle is used to model an open Gas Turbine cycle using the air statndard assumptions Combustor Fuel 3 2 Compressor Air • 1-2 Isentropic compression • 2-3 Constant pressure heat addition • 3-4 Isentropic expansion • 4-1 Constant pressure heat rejection 4 1 Turbine Products P 3 2 3 T 2 4 1 1 4 s v Air Standard Assumptions • Another common assumption used is that the air has constant specific heats equal to specific heats at room temperatures. When this is also used they are collectively referred to as the: cold-air-standard assumptions Mod: 11/15/01 Ideal Brayton Cycle - 2 The thermal efficiency of the ideal Brayton cycle is th h h wnet wout win qin qout q 1 out 1 4 1 qin qin qin qin h3 h2 1 c p (T4 T1 ) c p (T3 T2 ) 1 T1 (T4 / T1 1) equation (1) T2 (T3 / T2 1) Processes 1-2 and 3-4 are isentropic (adiabatic), therefore T2 P2 T1 P1 ( k 1) / k T3 P3 , and T4 P4 ( k 1) / k T2 T3 T2 T1 Also, P2 P3 and P4 P1 , therefore and T1 T4 T3 T4 Equation (1) becomes th 1 where rp T1 T 1 1 1 4 1 1 ( k 1) / k T2 T3 rp( k 1) / k P2 P1 P2 is the pressure ratio of the compressor and the turbine P1 Gas Turbine Improvements • Increase the gas combustion temperature (T3) before it enters the turbine since th = 1 - (T4/T3) Limited by metallurgical restriction: ceramic coating over the turbine blades Improved intercooling technology: blow cool air over the surface of the blades (film cooling), steam cooling inside the blades. • Modifications to the basic thermodynamic cycle: intercooling, reheating, regeneration • Improve design of turbomachinery components: multi-stage compressor and turbine configuration. Better aerodynamic design on blades (reduce stall). Jet Propulsion Cycle T 4 P=constant qin 3 5 6 2 1 qout • 1-2, inlet flow decelerates in the diffuser; pressure and temperature increase • 5-6, outlet flow accelerates in the nozzle section, pressure and temperature decrease P=constant s Propulsive Power Jet Engine Mass flow out Action force, FA Mass flow in Inlet velocity, Vin Exit velocity, Vexit Reaction force, FR Due to the action force F , the momentum of the air flowing A through the engine increases: d d F ( linear momentum change) = [ ( mV )] [ ( mV )] mV mV dt dt From Newton' s third law: F F Propulsive force A exit A F m (V V ) R exit in Propulsive Power = F V m (V V )V W P R aircraft exit in aircraft R in exit in PW8000 Geared Turbofan Engine • Twin-spool configuration: H-P turbine drives H-P compressor L-P turbine drives L-P compressor, on separated shafts • Gearbox to further decrease the RPM of the fan • More fuel efficiency • Less noise • Fewer engine parts From Machine Design Magazine Nov. 5, 1998