GAS HYDRATES

advertisement

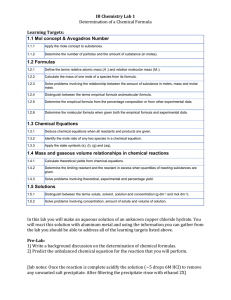

Case Study: Stratified Gas Hydrate Reservoir with Associated Free Gas Group Project PETE 680: Horizontal well Technology Presented By, Namit Jaiswal, Adejoke M Ibironke Objective 1. Gas Hydrates 2. Overview of horizontal well and designer well 3. Case description 4. Results 5. Conclusion 6. Recommendation Alaska Methane Hydrate Estimated Resource EILEEN TREND MPU 100% FREE GAS? 44 TCF KRU 39% DIU PBU 26% GAS HYDRATE & FREE GAS 60 TCF? GAS HYDRATE TARN TREND (After Collett, 1993) GAS HYDRATES – AN OVERVIEW Crystalline structures of ice that form cages around guest molecules Guests are gas molecules (methane, ethane, CO2, N2…) No chemical bond between guest and host lattice Physically stable with only partial occupancy Different structures sI, sII, sH, sT, …? Large amounts of gas molecules are entrapped within these cages Up to 180 volumes of gas (scf) per volume of hydrate Gas molecules can penetrate through the hydrate zone to form new gas hydrates at boundary Formation and growth occurs only under certain pressure and temperature conditions Hydrate formation conditions are high pressure and low temperature Reserves Estimation Gas Hydrate Production Methods Depressurization Gas Out Imperm. Gas Thermal Injection Gas Out Rock Imperm. Hot Brine or Gas Rock Inhibitor Injection Gas Out Imperm. Methanol Rock Hydrate Gas Hydrate Dissociated Hydrate Free-Gas Reservoir Gas Hydrate Dissociated Hydrate Dissociated Hydrate Impermeable Rock Impermeable Rock After Collett, 2000 Boundary Condition Gas zone Hydrate zone t Peq Po Pwf Radial distance Pin Algorithm for Performance of a Hydrate Reservoir Evaluation 1. Assume an average pressure pavg, and calculate gas compressibility cg using 1 cg p avg 2. Using the value of cg , calculate total compressibility and hydraulic diffusivity constant from the known reservoir parameters. ct c f c g 3. For a desired gas withdrawal rate, solve eqn q sc ZTp sc exp 2k H hTsc H p 2 in 2 p eq exp 4ZTS EI 1 h 1 H H BH p sc 1 Tsc Above equation has on both sides; it requires a numerical scheme to solve. As a special case, when there is no gas flow from the undissociated hydrate zone, so above equation is simplified to Above equation has on both sides; it requires a numerical scheme to solve. As a special case, when there is no gas flow from the undissociated hydrate zone, so above equation is simplified to q sc exp 4S H BH 1 h 4. Using the value of , solve below equation (1) and (2 R 2 t .......1 K d p eq p0 BH n 5. psc dR psc BH RTsc dt RTsc Using the value R*, Po and solve eq 3. and 4. q sc 1 ZTp sc p p 2k1 hTsc 2 1 2 o r 2 EI 4 1t 1 t .......2 and for the un-dissociated region is p 2 H p 2 in p 2 p eq r2 EI 4 t R *2 H EI 4 t H 2 in to obtained pressure profiles as a function of radial distance from the wellbore. 6. From the pressure values obtained in step 5. find pwf and calculate a new average pressure using pavg 7. po p wf 2 Using the new value of pavg, calculate new values of cg, ct and . Compare the new value of with that calculated in step 2. If the new value is within 10% of the old value, use the pressure profile generated in step 5. If not, go to step 3 and repeat Steps 4-8 till the consecutive values of agree. Overview of horizontal well technology What is horizontal well ? Parameter Effects 1. Skin Factor 2. Payzone thickness 3. Anisotropy Productivity by Well Testing 1. To obtain reservoir properties 2. To find total producing length 3. To estimate mechanical skin factor Gas Reservoir 1. Low Permeability Vertical Horizontal Small spacing Single is sufficient Requires difficult fracturing May or may not require Low productivity High productivity 2. High Permeability Vertical Horizontal High turbulence Low turbulence Frac-pac required Not required High production per unit ht. Produces less gas per unit length Low productivity High productivity due to long length hydrate Water and Gas Coning Vertical well Horizontal well Case Description Highly Stratified Gas Hydrate Reservoir 6 x 50’ 2’ 0.35’ Kh=15 md VERTICAL WELL ASSUMPTIONS FOR VERTICAL WELL RESERVOIR • • • Temperature for free gas zone is constant. Average viscosity is used for calculation. Individual well bore pressure are assumed taken from literature. • Pressure drop across tubing is negligible. Productivity for vertical gas well is calculated by using following equation: q 2 0.0007027 kh pe2 pwf re ' rw (1) zT ln Where, q = gas flow rate, Mscfd k= permeability, md h = Thickness, ft Pe =Pressure at external radius, re, Psia Pwf = well bore flowing pressure, Psia Z= average compressibility factor T = Reservoir temperature, R re = drainage radius, ft Graph of Pressure Vs production from vertical well Variation of productivity with payzone J vs h plot thickness. 0.08 J, Mscf/(day.psi 2) 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0 0 10 20 30 J ,s=0 J, s=+0.5 h,ft 40 50 60 Vertical Fractured Wells Any technique that helps to create fissures and openings in the reservoir rock of an oil and (or) gas formation, and help increase the flow of oil and (or) gas. Techniques Fracturing can either be Natural - created by faults in the formation) Artificial -This can be • Pneumatic - by the flow of high pressure compression of air. • Hydraulic - pumping of fluid under high pressure. Application Increase the flow rate of gas from low permeability reservoirs. Increase the flow rate of gas from wells that have been damaged. Connect natural fractures or cleats in a formation to the wellbore. Decrease pressure drop around well to minimize sand production. Decrease pressure drop around well to minimize problems with asphaltene or paraffin deposition. Increase the area of drainage. Connects the full vertical extent of a reservoir to a slanted or horizontal well. Candidate Selection Must have a need to increase the productivity index. A thick pay zone. Medium to high pressure. In-situ stress barriers to minimize vertical height growth. It will either be a low permeability zone or a zone that has been damaged (high skin factor). Must have a substantial volume of gas in place. A fractured vertical well behaves much like a horizontal well. Advantages of Fractured Vertical Wells Can be used in thick formations Not affected by low vertical permeability Disadvantages of Fractured Vertical Wells No control over the fracture orientation Possibility of uncontained fracture growth resulting in excessive gas or water influx. TYPES OF FRACTURES INFINITE-CONDUCTIVITY FRACTURES UNIFORM FLUX FRACTURES FINITE-CONDUCTIVITY FRACTURES Assumptions Drainage volume is box shaped The well fully penetrates the formation There is no restricted entry to flow The production is predominantly stabilized flow for all layers The effect of non-Darcy flow is ignored The rock property in each layer is the same Equations FCD k f bf kx f 0.0007027 Kh Pe2 Pwf2 q r ln e S rw ZT RESULT Comparism Between Two Reservoir Pay Thicknesses 1400 1200 Pressure (psia) 1000 800 600 400 200 0 40000 90000 140000 190000 240000 Gas Flow Rate (Mscf/D) Pay = 50ft Pay = 20ft 290000 340000 Conclusion Vertical fracture well productivity decreases with pay thickness Fracture can only be beneficial when permeability is relatively low For the gas hydrate reservoir, it is expedient to perforate in the free gas zone SLANT WELL α Definition •A directionally drilled well, that is inclined at an angle α to the vertical. •α is usually between 30˚-75˚ to be effective α Reason for use & Areas of Practical Application To reduce the cost of drilling several wells from a single platform To allow extraction of oil/gas from areas unreachable conventionally In reservoir with down-dip For formation with low permeability to gas The Great Lakes, along the shores of Lake Michigan and Huron In the Coalbed Methane field of Valencia Canyon in Northern San Juan basin of Colorado. In the Greater Green River Basin of Colorado. Equations ss 41 2.06 hD h rw 56 1.865 kh kv tan 1 k v k h tan log hD 100 rw rw exp s s J s J v ln re rw ln re rw Result: A Graph of Productiovity Index Ratio of Slant to Vertical Wells vs Slant Angle For Pay Thickness = 20ft 1.035 1.03 1.025 Js/Jv 1.02 1.015 1.01 1.005 1 0.995 30 35 40 45 50 55 60 65 70 Slant Angle (degree) Kv = 0.0001md Kv = 0.001md Kv = 0.01md Kv = 0.1md 75 80 A Graph of Productivity Index Ratio of Slant to Vertical Wells vs Slant Angle For Pay Thickness = 50ft 1.04 1.035 1.03 Js/Jv 1.025 1.02 1.015 1.01 1.005 1 0.995 30 35 40 45 50 55 60 65 Slant Angle (degree) Kv = 0.0001md Kv = 0.001md Kv = 0.01md Kv = 0.1md 70 75 80 Conclusion The slant well is highly dependent on the vertical permeability When the kv is low, then productivity will be low Gas migrates vertically upward and because the kv is very low the productivity turned out low The result shows that the slant well has a higher productivity than the vertical well Model of the given field Staircase Horizontal Well A steady state equation for gas flow in a Horizontal section q 2 0.0007027 k h h p e2 p wf a g zT ln 2 a 2 L / 2 h h ln L/2 L 2rw a 0.5L0.5 0.25 2reh / 4 4 s m 0.5 Where, q = gas flow rate, Mscf/day kh= permeability, md h = Thickness, ft Pe =Pressure at external radius, re, Psia Pwf = wellbore flowing pressure, Psia Z= average compressibility factor T = Reservoir temperature, R re = drainage radius, ft r'w =effective wellbore radius, ft = SQRT (kh/kv) Sm = mechanical skin factor Assumptions Negligible pressure drop. Pt Pgravity Pfriction Pacceleration Permeability of each zone is same No production from vertical sections. Open hole completion to increase hydrate production in long run. Production Plot for L=500 ft. for staircase horizontal well Impact of vertical permeability on staircase horizontal well production kv=0.0001 md kv =0.001md kv =0.01md 350 kv =0.1 md 300 Pwf (psi) 250 200 150 100 50 0 0 50000 100000 Flowrate (Mscf/d) 150000 Productivity Plots for staircase. Veritical permeabilty Vs Gas flow rate Veritic al permeabilty Vs Gas flow rate L=1000 ft 0.12 0.1 vertical perm, kv(md) vertical perm, kv(md) 0.12 0.08 0.06 0.04 0.02 0 0 0.02 0.04 0.06 0.08 Flowrate (Mscf/d) 0.1 0.12 0.14 Millions 0.1 0.08 0.06 0.04 0.02 0 0 0.05 0.1 0.15 0.2 Flowrate (Mscf/d) h=50 ft h=20 ft h=50 ft h=20 ft 0.25 0.3 Millions Multilateral Wells Initialization For stratified well the partial differential equation, Pj denoting the pressure in the jth layer, k jx 2 p j x 2 k jy 2 p j y 2 k jx p j y 2 j c jt p j t Bo q H ( y) ( x x w ) ( z z w ) Cases : Communication Shell Barrier Multilateral well in hydrate reservoir with no communication A Steady state equation for Multilateral Well q 0.0007027k h h p e2 p wf2 Fre h h s m g zT ln ln L mnL 2mrw Where, F=4,2,1.86 and 1.78 for n=1,2,3,4. m =number of levels. For this case, m=6 and n=1. Productivity Plot for L=500 ft. for multilateral well Veritical permeabilty Vs Gas flow rate L=500 ft vertical perm, kv(md) 0.12 0.1 0.08 0.06 0.04 0.02 0 0 0.02 0.04 0.06 0.08 Flow rate (Mscf/d) h=50 ft h=20 ft 0.1 0.12 0.14 Millions Productivity Plot for L=1000 ft. for multilateral. Veritical permeabilty Vs Gas flow rate L=1000 ft vertical perm, kv(md) 0.12 0.1 0.08 0.06 0.04 0.02 0 0 0.05 0.1 0.15 0.2 Flow rate (Mscf/d) h=50 ft h=20 ft 0.25 0.3 Millions Sinusoidal Well Pressure Drop Equations Comparison Conclusion: • A single undulating well outperforms up to total of three horizontal wells drilled in each isolated layers. • 2) In order for a cased horizontal well to achieve the performance of an open hole horizontal well, high shot densities and long penetration lengths are needed. • 3) Multiple hydraulic fractures are more attractive for cased horizontal wells to achieve substantial increase in flow rates. There are optimum number of hydraulic fractures in order maximize production rates with cost consideration. • 4) In multiple thin-bedded sand layers, drilling horizontal well in each layer may not be feasible. Hydraulic fracturing of horizontal well to reach out to remaining sand layer may not easily achievable either. In such reservoir, drilling an undulating well seems to be more suitable completion technique. 1) Conclusion Productivity per unit length is highest in vertical well\ Overall productivity is highest for multilateral well Recommendation Incorporating in some way to productivity equation Namit