INDUSTRY

advertisement

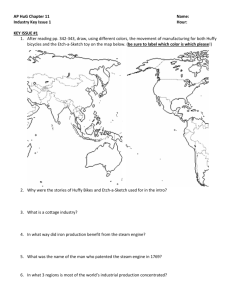

CHAPTER 11: INDUSTRY Key Issues: 1. Where is industry distributed? 2. Why do industries have different distributions? 3. Where is industry expanding? 4. Why are location factors changing? Where is industry distributed? 1. Northwestern Europe 2. Eastern Europe 3. Northeastern North America 4. East Asia Northwestern Europe Four Major Regions: 1. United Kingdom 2. Rhine-Ruhr Valley 3. Mid-Rhine 4. Northern Italy United Kingdom Dominated manufacturing from the late 1700's through the 1900's. Industrial Revolution originated here. The “revolution” was really the “collective invention of hundreds of mechanical devices.” The UK lost dominance in the early 20th century as its factories became outmoded. Expanded industrial production in the late 20th century by bringing in new high-tech industries that serve the European market. United Kingdom Industrial Region The British government has actively worked to attract high-tech industry by lowering taxes on businesses, reducing government regulation, reducing government ownership of economic activity and using new technology such as computers. Transportation The need to transport inputs and outputs caused the development of faster transportation systems. The two earliest were: 1. Canals 2. Railroad Rhine-Ruhr Valley Innovations in Belgium, Germany and France helped to expand industry from the UK to mainland Europe. Iron and steel production is dispersed throughout this region due to proximity to coal and iron ore. This has encouraged heavy metal industries like locomotives, machinery and arms. Rotterdam's location at the mouth of the Rhine has made the Dutch city the largest port in the world. Mid-Rhine This location is mostly determined by proximity to markets rather than resources. Frankfurt: consumer goods. Stuttgart: high value goods. Mannheim: chemicals Alsace Lorraine: near ironore field, leading steel producer. Northern Italy Po River Basin: textile industry began in 19th Century. Half of the country's population located here and Two thirds of Italy's industry. Two attractions: lower wage workers and hydro-electric power. Eastern Europe Eastern Europe Central Industrial District: Centered around Moscow. Located close to markets. Few natural resources. High skilled workers make textiles, chemicals. St. Petersburg: shipbuilding, early industrial area Volga: grew during WWII, oil and natural gas, automobiles Ural: contains more than 1000 types of minerals, most diverse mining region in world. Industry located near resources. Lacks energy sources. Kuznetsk: largest reserves of coal and iron ore. Produces steel Eastern Ukraine: Donetsk coal field one of largest in world. Largest producer of pig iron and steel in this region Silesia In southern Poland and northern Czech Republic. Steel producer near coal fields. North America U.S. Industrial Areas New England: Oldest cotton textiles. Provided cheap immigrant labor in past. Now has expensive labor. Middle Atlantic: Largest US market. Port cities depend on foreign markets or imported raw materials. Finance, communications and entertainment in New York attracts other industry. Mohawk Valley: Connects NY City to Great Lakes via the Erie Canal. Early important industrial center for food products and steel. Niagara Falls is a source of cheap hydro-electric power. Pittsburgh-Lake Erie: Early steel production region due to proximity to iron ore and coal in Appalachian Mountains. Western Great Lakes: Chicago serves as a transfer point for a variety of transportation systems. This has attracted car manufacturers and related industries. Canada (North American Region) St. Lawrence ValleyOntario Peninsula: close to Canadian markets. Access to energy (Niagara Falls) Products: steel, automobiles, aluminum, paper, flour, textiles and sugar. East Asia East Asia Japan East Asia's largest obstacle to industrial growth was isolation from markets Japan recovered from WWII (1945) by selling products at low prices Low labor costs (wages) allowed Japan to undercut prices in Europe/US As other east Asians entered the market, Japan changed strategies It began producing high quality products: automobiles, ships, cameras, stereos and TVs required a highly skilled labor force. China World's second largest manufacturer. Manufacturing is clustered along the east coast. Review: Key Issue One Where is Industry Distributed? In your notebook, on the page with information about the four major industrial regions, briefly describe the reason each industrial region located where it did. 1. Northwest Europe 2. Eastern Europe 3. North America 4. East Asia Answer to Review of Key Issue 1 1. Northwestern Europe: Industry began here. (Before Industrial Revolution manufacturing, such as cottage industries were dispersed.) New technology caused manufacturing to concentrate. 2. Eastern Europe: Proximity to resources (coal, iron ore)caused industry to locate in some places, but proximity to markets is a major factor for the central region around Moscow. Answers to Review of Key Issue 1 3. North America: Despite initial distance from markets, industry emerged around transportation routes such as the Great Lakes, the Atlantic Coast, the Erie Canal and later railroads. The resources of the northeast as well as its large population (market) attracted industry. 4. East Asia: Also far from markets, Japan and China led the way with low cost labor that kept product prices low. Japan has evolved its strategy by shifting to high value goods requiring a skilled labor force. Key Issue 2 Why Do Industries Have Different Distributions? Situation Factors What are the costs of transporting materials to and from the factory? Owners will seek to locate factories close to resources and to markets. Saab factory in Germany. Proximity to Inputs Factories locate near inputs when they are large and bulky. 1. Copper Industry: Bulk reducing. Concentration mills and smelters located nearby. Refineries can be located elsewhere. 2. Steel Manufacturing: Need energy (coal) and iron ore to produce steel. As steel making technology has changed, new smaller mills (minimills) can now locate nearer to markets rather than inputs. US steel manufacturing has declined as competitors have gained more of the market. Steel mill in eastern Germany Proximity to Markets Bulk Gaining Industries: manufacturing that creates a product that is heavier or bulkier than its components, will locate as close to markets as possible in order to reduce transportation costs. Proximity to Markets II Fabricated Metals and Machinery: a fabricated metal factory takes individual parts and adds them together to create a more complex product. Examples: Refrigerators, TVs, air conditioners, automobiles, architectural components (steel) Proximity to Markets III Single-Market Manufacturers: These factories will locate close to their customers. Auto parts dealers are clustered near automobile factories. Perishable Products: This can be food, newspapers or any product that has a short life-span. Modern technology is changing the requirements for these companies. Transportation Low costs are important in keeping costs down. The farther the product is transported the CHEAPER cost per mile/kilometer. Why? because the labor of loading and unload products is the same regardless of the distance traveled. boat is the cheapest form of transport for long distances air may be preferred if quick delivery is desired. Break-of-Bulk Points Sometimes the cost of one mode of transport is lower for some products and inputs than for others. This means some businesses will use a BREAK-OF-BULK POINT where transfer of products from one type of transportation to another can be done. SITE FACTORS Labor, Land and Capital: Labor is the most important site factor and determines the location of key industries. Labor Intensive Industries: produce products that's cost is made up of a high percentage of labor costs. Textiles are an example. Textile and Apparel Spinning: done in low wage countries such as China and south Asia. Textile and Apparel Weaving: Even more labor intensive than spinning. Also located in low wage countries. Low labor costs offset transportation costs. SITE FACTOR: LABOR (continued) Textile and Apparel Assembly: Textiles are made into: clothing, carpets, home furnishings and in cars. Again: Asia, because of low cost labor, is the location of most apparel assembly industries. Textile factory in China. Are you seeing spinning, weaving or apparel assembly? SITE FACTOR II: LAND What do manufacturer's look for in land? Climate Amenities Education Facilities Low-cost energy sources SITE FACTOR III: CAPITAL Financing, raising money for manufacturing projects, is essential to developing industry. Location of Capital has influenced the development of the automobile industry and Silicon Valley in California. Review of Key Issue 2: Why do Industries Have Different Distributions? Directions: On the back of a piece of notebook paper, answer the following questions: 1. What two factors influence where an industry locates? 2. Bulk-reducing industries locate near to resources or markets? 3. What site factor influences the location of labor intensive industries? 4. A fabricating plant is an example of a bulk gaining or bulk reducing industry? Answers to Key Issue 2 Review: 1. Proximity to inputs and proximity to markets influence where industries locate. 2. Bulk reducing industries locate near to resources. 3. Labor intensive industries are most concerned with labor costs. 4. A fabricating plant is a bulk gaining industry. That's the end of Key Issues I and 2! Key Issue 3: Where is industry expanding? Changing Distribution Within MDC's Intraregional Shifts in Manufacturing Cities were original locations of much manufacturing. Close to labor and capital but land eventually became too expensive. Factories began to locate outside of cities where land was cheaper. Modern factories in rural/suburban areas can be one story. This is a more efficient layout than the urban, multistory factories. These newer factories are also closer to major highways for inputs/outputs. Interregional Shifts in Manufacturing Southern and Western United States The northeastern US lost 1 million manufacturing jobs in the last 30 years. Steel, textiles and fabricated metal in NY and Pennsylvania especially Since 1970's manufacturing has grown by 1/6 in the South and West. For years, South remained agricultural due to lack of infrastructure. Government policy (TVA, road building) has helped the South catch up. Southern Right-to-Work Laws were a powerful attraction for employers. Right-to-Work Laws Right-to-Work states require “open shops.” “Open shops” allow workers to belong to the union or not. This makes it difficult for unions to organize workers. A “Closed Shop” requires union membership as a requirement of working at that factory or business. The effect of an open shop is to keep job costs (wages and benefits) low. Southern and Western Manufacturing In the south: steel, textiles, tobacco products and furniture industries are widely dispersed around the region. Gulf Coast: chemicals, petrochemical manufacturing and food processing In the west: Panama Canal (1914) had effect of bringing the west coast closer to east coast markets. Manufacturing activity include: aircraft manufacturing, clothing and textiles, furniture and food processing low-wage workers from Mexico and Asia help make the west coast attractive to employers. Interregional Shifts in Western Europe Shifts in Europe, unlike the US has seen manufacturing shift because European governments have encouraged it. They use incentives to attract industry to poor regions within Europe and discourage manufacturing in rich areas. The European Union (EU) provides money (Structural Funds) to develop manufacturing facilities. An is example is Spain which has developed car and textile industries. New Industrial Regions Asia China is by far the leading new manufacturing center. Steel production reflects shift from MDC's to LDC's 1980 – 80% of all steel was produced in MDC's Since then, steel production has shifted to LDC's China now produces 30% of world's steel. US steel has dropped to only 10%, steepest of MDC's China has become the one of the world's largest manufacturer for two reasons: 1. a large supply of low wage workers 2. a large supply of potential customers Transformation began in 1990's when China's communist government began opening the country to outside business investment. New Industrial Regions Latin America Mexico and Brazil are leading industrial areas in Latin America. Most manufacturing is centered in largest cities: Mexico City and Sao Paulo. Until 1990's, Latin American countries discouraged trade with Europe and US in an effort to encourage support of local manufacturing. Instead, this policy caused inefficient factories and led to inflation and debt. Since the 1990's, Latin American countries have engaged in more free trade and seen their economies improve as a result. “Maquiladoras” are factories located along the US border. This allows American manufacturers to pay lower wages in factories relatively close to the US. They are not close enough for “Just-In-Time” Delivery. Even low Mexican wages cannot compete with those of Asia. Review of Key Issue 3: Where is Industry Expanding? 1. Within the US, which regions of the US have seen an increase in manufacturing? 2. How have interregional shifts differed in Europe compared to the US? 3. What two factors encouraged the expansion of manufacturing after the Chinese government changed its policies? 4. What are two disadvantages of “Maquiladoras”? Answers to Key Issue 3: Where is Industry Expanding? 1. Southern and western states 2. The Europeans actively encouraged shifts in manufacturing from more developed regions to less developed regions. 3. The Chinese were able to provide a large, low wage labor force and a very large potential market. 4. “Maquiladoras” are too far away for “just-in-time” delivery and even though wages are low compared to the US, they are much higher than wages in Asia. Key Issue 4: Why Are Location Factors Changing? Attraction of New Industrial Regions Proximity to Low Cost Labor: The shift of factories from MDC's to LDC's has been especially intense for the textile industry. Per hour wages in the clothing industry by country. Percentage of clothing made in the US 1994-2004. Clothing made in LDC's around the world. Key Issue 4: Why are locations changing? Outsourcing New International Division of Labor: Multinational corporations select those manufacturing operations that can be done by unskilled labor in LDC's and move those jobs to LDC's, leaving skilled jobs in MDC's. Outsourcing: This practice allows multinational corporations to maximize their profits by having other companies produce some needed parts for less than the multinational corporation could produce the items itself. Renewed Attraction of Traditional Industrial Regions Proximity to Skilled Labor: Some industries need skilled labor to produce their products. Unlike Fordism, where workers performed repetitive jobs that needed little training, skilled workers today are expected to complete complex tasks, solve problems and work in teams with other workers. This approach is known as postFordism. The computer industry requires a skilled work force and uses post Fordism approaches to manufacturing. Renewed Attraction of Traditional Industrial Regions Just-in-Time Delivery: Manufacturers order inputs at the very day or moment it is needed. This reduces the cost of maintaining a large warehouse full of needed parts. This arrangement means suppliers must be very close to the manufacturers in order for this system to work. Two Potential Risks: 1. Labor unrest could interrupt production throughout system. 2. Bad weather could also interrupt production. Review of Key Issue 4: Why Are Location Factors Changing? 1. What has been the primary reason that textile manufacturing has moved to LDC's? 2. What is the new international division of labor? 3. What is outsourcing? 4. How is “just-in-time” delivery causing factories to locate in traditional industrial regions? Answers to Key Issue 4 1. Low Wages 2. The practice of using low skilled, low wage workers in LDC's to complete simpler tasks and skilled labor in MDC's to carry out more complex tasks. 3. Outsourcing is buying parts from suppliers rather than making these components by the main manufacturer. 4. In order for “Just-In-Time” manufacturing to work, suppliers must be located close to the manufacturing customer using the parts.