Industrial Revolution

advertisement

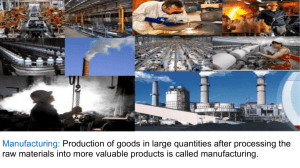

Chapter 11: Industry The Cultural Landscape: An Introduction to Human Geography Where is Industry Distributed? • Origin of industry – Industry: production of goods in factories – From cottage industries to the Industrial Revolution Figure 11-2 Where is Industry Distributed? • Origin of industry – Impacts of Industrial Revolution • Iron – Steam Engine • Coal – Energy source • Transportation – Canals & Railroads • Textiles – Cottage industry to factories • Chemicals • Food processing Where is Industry Distributed? • Industrial regions: Europe – Late 19th & early 20th c. – United Kingdom: steel & textiles to high-tech industry – Rhine-Ruhr Valley: iron & steel – Mid-Rhine: consumer market & iron ore – Po Basin: textiles – NE Spain: textiles & motor vehicles – Moscow, St Petersburg, Volga, Donetsk, Silesia: wide variety Figure 11-4 Where is Industry Distributed? • Industrial regions: N. America – Arrived later but spread faster – NE U.S. • New England: cotton textiles • Middle Atlantic: largest U.S. market • Mohawk Valley: steel & food processing • Pittsburg-Lake Erie: steel • W Great Lakes: transportation hub; steel • S California: aircraft industry; today = variety – SE Canada • SE Ontario: steel, motor vehicles, textiles, etc. Figure 11-5 Where is Industry Distributed? • Industrial regions: East Asia – Isolation from world markets – Japan • Large quantity of goods to be sold at low prices • Today = high quality automobiles, electronics, etc. – China • Largest labor supply • 1 of largest consumer markets Industrial Regions Figure 11-3 Why Are Situation Factors Important? • Proximity to inputs – Bulk-reducing industries • Inputs weigh more than outputs – Examples: • Copper – – – – Mining Concentration Smelting Refining • Steel (iron alloy) – 19th c. – 20th c. Figure 11-8 Why Are Situation Factors Important? • Proximity to markets – Bulk-gaining industries • Product gains volume during production – Examples: • Fabricated metals – Making parts from metal – Bend, forge, stamp, form & parts • Beverage production – Water = largest input Figure 11-10 Why Are Situation Factors Important? • Proximity to markets – Single-market manufacturers • Specialized • “Just-in-time” delivery – Perishable products • Delivered ASAP – Fresh food – Newspapers Why Are Situation Factors Important? • Ship, rail, truck, or air? – The farther something is transported, the lower the cost – 4 modes • • • • Truck = short-distance travel Train = longer distances (1 day +) Ship = slow, but low cost Air = most expensive, but fast – Break-of-bulk point: mode transfer location Why Are Site Factors Important? • Labor: most important – Labor-intensive industries • Textiles (less-skilled, low cost labor) – Textile & apparel spinning (spin fibers to make yarn or thread) – Textile & apparel weaving (weave or knit yarn or thread into fabric) – Textile & apparel assembly (cut & sew fabric into products) – Capital-intensive industries Textile Production Figures 11-16, 17, 18 Why Are Site Factors Important? • Land – 1st factories in cities – Today: rural sites • Space for production line • Environmental factors – Climate, topography, recreation, culture, energy, etc. • Capital – Need $ to start or expand factories Why Are Location Factors Changing? • Attraction of new industrial regions – Changing industrial distribution in MDCs • Interregional shift within the U.S. – Right-to-work laws – Textile production Figure 11-21 Why Are Location Factors Changing? • Interregional shifts in Europe – Convergence shifts » E & S Europe – Competitive & employment regions » W Europe Figure 11-23 Why Are Location Factors Changing? • Attraction of new industrial regions – International shifts in industry • East Asia – China, Japan, S Korea • South Asia – India • Latin America – Maquiladora plants – Changing distributions World Steel Production Figure 11-24 Why Are Location Factors Changing? • Attraction of new industrial regions – Outsourcing • Transnational corporation • New international division of labor • Vertical integration Figures 11-25, 26 Why Are Location Factors Changing? • Renewed attraction of traditional industrial regions – Proximity to skilled labor • Fordist (mass production) • Post-Fordist (lean production) • Just-in-time delivery The End.