PPTX

advertisement

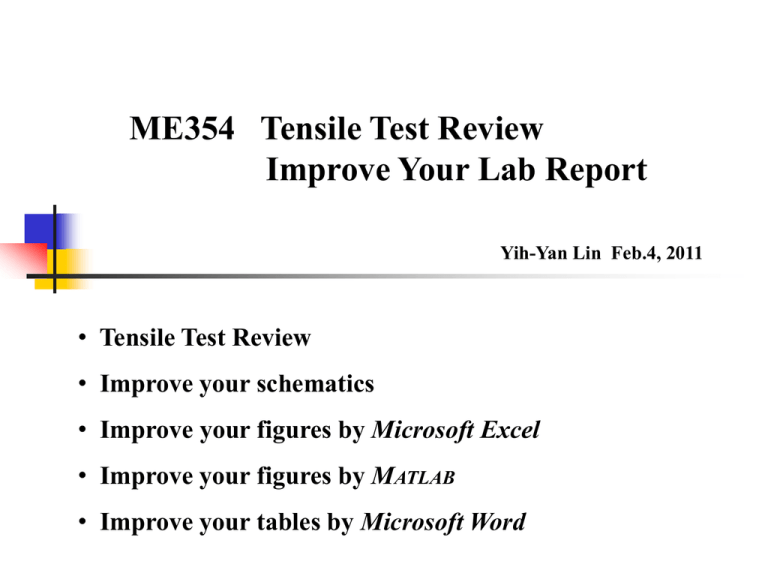

ME354 Tensile Test Review Improve Your Lab Report Yih-Yan Lin Feb.4, 2011 • Tensile Test Review • Improve your schematics • Improve your figures by Microsoft Excel • Improve your figures by MATLAB • Improve your tables by Microsoft Word Tensile Test Review Data Analysis of Lab 4 — Tensile Test Topic A36 Steel Al 6061 T-6 PMMA Polycarbonate 1. Engineering stress and strain curve √ √ √ √ 2. Ultimate Strength* √ √ √ √ 3. Modulus of Elasticity and Yield Strength* √ √ 4. Modulus of Resilience** √ √ Modulus of Toughness** √ √ √ √ 5. True Fracture Strength* √ √ √ √ Percent Reduction in Area* √ √ √ √ Percent Reduction Elongation* √ √ √ √ 6. True stress and strain** √ 7. Strength Coefficient and Strain Hardening Exponent*** √ * Statistical Analysis (average and standard deviation) ** Pick up only one set of the data *** Error Analysis Use appropriate schematics, tables and figures in your report. Load Strains Tensile Test Review – MATLAB Code examples Engineering stress and strain curves Modulus of Toughness Enlarge the pictures to see the details. Improve Your Schematics Microsoft Office Visio Microsoft Office Word (My research in UW, 2010) (My modal test lab report in 2002) Fourier Analyzer Digital Analog A/D card Anti-Aliasing Filter Charge Amplifiers Input and Output Signal Trigger Signal k k Hammer Accelerometer H=0.6 cm L=111.6 cm W=5.3 cm Microsoft Office Powerpoint (Lecture Slide, ME354 W2011) Dogbone specimen Don’t use Microsoft Windows Paint! gage section grip grip fillet Improve Your Figures by Microsoft Excel Excel Default Figure 600 5 500 2 7 9 400 A36 300 6061 8 PC 200 PMMA 100 1 0 0 0.2 0.4 4 1. 2. 3. 4. 5. 0.6 0.8 1 3 1.2 6 1.4 2 Inside major tike mark type Must have axis labels and units Keep decimal places consistent Change axis color form grey to black Remove horizontal grid line 6. 7. 8. 9. No chart area border Need plot area border Move the legend inside the plot area No markers Improve Your Figures by Microsoft Excel (cont’) What are you going to tell your readers? 600 Ultimate Strength: Steel > Al Modulus of Toughness: Steel > Al Modulus of Elasticity: Steel > Al Yielding Strength: Steel ~ Al Stress s (MPa) 500 A36 Steel 400 300 6061 T-6 Aluminum 200 100 0 0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 Strain e (mm/mm) 600 A36 Steel 500 Failure Strain Ultimate Strength 6061 T-6 Aluminum Stress s (MPa) Polycarbonate 400 Polymethylmethacrylate 300 200 100 0 0.0 0.2 0.4 0.6 0.8 Strain e (mm/mm) 1.0 1.2 1.4 Improve Your Figures by Microsoft Excel (cont’) 2. Decimal place 1. Greek alphabet: “Times New Roman” to “Symbol” Font style: Times New Roman Font style: Symbol 600 4. Change to black axis (default is gray color) 500 A36 Steel 6061 T-6 Aluminum A36 Steel Polycarbonate Stress s (MPa) 1. Greek alphabet 400 3. Inside tick mark type Polymethylmethacrylate 6061 T-6 Aluminum 300 4. Axis color: solid and black 200 PMMA 100 Polycarbonate 3. Inside tick mark type 0 0.0 0.2 2. decimal place:1 0.4 0.6 0.8 1.0 1.2 1.4 Strain e (mm/mm) 1. Greek alphabet • No horizontal grid lines. (You may keep both horizontal and vertical grid lines or remove both of them, but don’t keep either one) • Remember axis labels and units. (physical parameter, Greek alphabet, unit . eg: Stress s (MPa) ) • If you don’t have color printer, use black color, gray color and different line styles to distinguish different data sets. • Either “legend” or “text box in the plot” will suffice to help distinguish different data sets. Improve Your Figures by Microsoft Excel (cont’) Looks good, but could be better. 8.00 Displacement, d (mm) 7.00 6.00 5.00 4.00 3.00 2.00 Round tube 1.00 C- Channel 0.00 0 100 200 300 400 500 Load Cell Readings, RLC (N) • Distinguished by types of line style and types of data-point symbol– either one of them would suffice. • Textboxes by the line might be better than legend. 8.00 8.00 7.00 7.00 Round tube 6.00 C- Channel 5.00 Round tube 6.00 Displacement, d (mm) Displacement, d (mm) Improve Your Figures by Microsoft Excel (cont’) 4.00 3.00 2.00 1.00 5.00 C- Channel 4.00 3.00 2.00 1.00 0.00 0 100 200 300 400 500 Load Cell Readings, RLC (N) • Different data sets are distinguished by types of data-point symbol. • Lines are only for showing the trend of the data. 0.00 0 100 200 300 400 500 Load Cell Readings, RLC (N) • Different data sets are distinguished by types of line style. • Types of data-point symbol are only for showing numbers of data point. Improve Your Figures by MATLAB MATLAB Default Figure – much better than Word 1. 2. 3. 4. 106 M, 10-6 m Decimal places inconsistent Unit, Legend and Textbox Different line styles to distinguish different data sets Improve Your Figures by MATLAB (cont’) Arrows and textboxes MATLAB code Legend and different line style Improve Your Tables by Microsoft Word No unit Word Default Figure SG2a (θ = -17) εθ Percent (με) Error εmeas (με) εmeas (με) SG2b (θ = 25) εθ Percent (με) Error εmeas (με) SG2c (θ = 70) εθ Percent (με) Error -224 -211.39 5.97 -170 -181.85 6.52 53 36.33 45.88 -450 -429.41 4.79 -348 -363.61 4.29 105 83.20 26.20 -675 -904 -634.07 -845.45 6.46 6.93 -528 -707 -545.46 -727.30 3.000000 2.79 152 201 124.80 166.39 22 20.80 Avoid two rows in a unit This table has Times New Roman, Calibri and italic, three font styles. Only three full-width lines; no vertical lines Improve your Figure Table E.6. Stress and Strain at Strain Gage 2 for C-Channel. Title SG2a (θ = -17°) Headings Body SG2b (θ = 25°) SG2c (θ = 70°) εmeas (με) εθ (με) Error (%) εmeas (με) εθ (με) Error (%) εmeas (με) εθ (με) Error (%) -224 -211.39 5.97 -170 -181.85 6.52 53 36.33 45.88 -450 -429.41 4.79 -348 -363.61 4.29 105 83.20 26.20 -675 -634.07 6.46 -528 -545.46 3.20 152 124.80 21.79 -904 -845.45 6.93 -707 -727.30 2.79 201 166.39 20.80 • Use “Times” font style. Avoid “Calibri” and “italic”. Use “italic” only when you emphasize something, refer to a book name or show writing style. Italic may help Greek alphabets look better. • Keep font size and font style consistent in your report. • Don’t forget the units. • Keep decimal place consistent and decimal place more than three might be meaningless Thank you.