here

advertisement

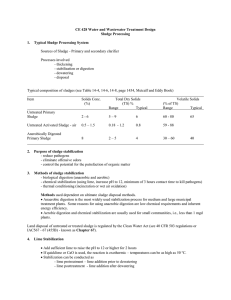

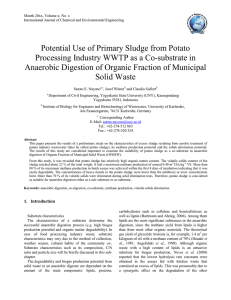

Optimizing the Digestion Process to Maximize Methane, Power and Payback – A Discussion of Treatment, Co-Generation and the Evolving Methods of Paying Off the System Joseph C. Cleary, P.E., BCEE Principal HydroQual, Inc. 1200 MacArthur Boulevard, Mahwah, NJ 07430 jcleary@hydroqual.com Michael Curtis, Ph.D., P.E. Senior Vice President Fuss & O’Neill 146 Hartford Road, Manchester, CT 06040 mcurtis@fando.com Outline Anaerobic Digestion Overview and History Available Technologies and Configurations Design Considerations & Optimization Project Delivery Approach Paying for Alternative Energy Upgrade Renewable Energy, Carbon Credits and Bonds Entrepreneurial Approach and Investor Partnering Summary Anaerobic Digestion Overview and History Anaerobic Digestion Process History 1940’s – Low rate anaerobic municipal sludge digesters 1950-60’s – Two stage and heated digesters 7 Thermophilic 1960-70’s – Anaerobic contact process used in meat packing and food industry wastewater. 1965-85 – Development of Egg-Shaped Digesters for municipal sludges 1966-68 – Fixed film reactor lab studies 1972 – First full-scale anaerobic filter with pall rings (Celanese) History 1980-85 – Hybrid anaerobic filter (ADI) Downflow filter (Bacardi) Upflow anaerobic sludge blanket (UASB) (Biothane & Paques) Fluidized Bed 1990s – Expanded Granular Sludge Bed (EGSB) (Biothane) 1990s-2000 – Pulsed sand bed system (Ecovation) 2000-Present - Co-Gen Advancements, “Carbon Engineering” TM Number of Industrial Installations Industrial Sector Beverage Food Pulp and paper Chemical/pharmaceutical Dairy/Ice Cream/cheese Sewage Meat/poultry/fish Other TOTAL Reference: Chemical Engineering April 2003 Number 623 310 137 107 67 67 23 265 1599 Typical Industrial Application Reactor Configurations Reference: R.E. Speece, 1996 Design Considerations Organic loading rate (e.g. Kg COD/M3-day) Gas production rate Alkalinity & pH balance Reactor configuration / mixing Concentration of biomass inventory Volatile Solids / Mass Reduction Temperature / Heating Toxicity Inhibition Biosolids Quality – Pathogen Destruction Digester Process Optimization Improved Mixing New Low-Energy Mixing Enhancements Increase Methane Production / VS Reduction Staged Reactors Temperature (meso / thermophilic) pH / Alkalinity Feed Rate Optimization Co-Digestion – Carbon Engineering TM Project Delivery Approaches Design/Bid/Build (most traditional) Design/Build (D/B) Design/Build/Operate/Maintain (DBOM) Design/Build/Own/Operate/Maintain (DBOOM) So How do You Pay for it ?? Paying for Alternate Energy Upgrade Resource is Methane Payback Based Upon Avoided Power Purchase and Much More 1 mgd plant with Flared, well-maintained digester 20,000 SCFD – 60% Methane – 30 kW $45K per year at $0.16 per kWhour Helps – but will not pay for $ 0.5 – 1M investment Paying for Alternate Energy Upgrade Must Install Gas Treatment – Sulfur and Siloxanes Condensate Collection Pressurization Co-Generation Unit (turbine, engine, etc.) Electric Switch Gear Heat Exchange Capabilities (Exhaust / Engine Jacket Heat to Process) Not Rocket Science – but Not Trivial! Co-Gen Units Fuel Cell – 7K per kW 80-90% Efficient Power and Heat Micro Turbine 4 K per kW Paying for Alternate Energy Upgrade First Consideration – app. / up to 50 % Sludge Mass Reduction – sizable Sludge Disposal Cost Reduction Possible Elimination of some / all Fossil Fuel Use to Maintain Digester Temperature Avoided Power Purchase – Power Parasitized On-Site - Highest Value Low Energy Plants (RBC’s, Trickling Filters) can actually export Power to Grid - Net Metering Research Renewable Energy Credits and Carbon Credits Renewable Energy Credits (REC’s) for generated power Current value approx 3-7 cents per kWh Based Upon Utility Mandates to Offer Increasing levels of Renewable Power Capitalism at Work – Given Market Brokers – Buyers - Sellers Value of Power ($0.05 per kWh) $0.21 per kWH $55K for 30 kW Installation Renewable Energy Credits and Carbon Credits Carbon Credits market still very young Adds some revenue now Has Potential to add very significant revenue stream for larger projects Example – Mid-Size Digester Offsetting 500,000 gal fuel oil per year Reducing 5,000 tons/year CO2 Ten year period Total value approx $500,000 Renewable Energy Credits and Carbon Credits Purchase of Carbon Credits and REC’s Lump Sum Up front – Buy Down Capital Long-Term Annuity Approach Need Good Financial Analyst Long-Term - Carbon Costs Going to Rise New Jersey Programs http://www.njcleanenergy.com/renewableenergy/programs/renewable-energyincentive-program New Jersey Clean Energy Program Large and Growing Never Take ANYTHING on Face Value Programs Set up for Flexibility and Success NJ BPU BioPower Rebate Program $1,500 - $2,000 per kW at Typical Installation Clean Renewable Energy Bonds The Energy Policy Act of 2005 (P.L. 109-58) establishes Clean Renewable Energy Bonds. A "CREB" is a special type of tax credit bond providing the equivalent of an interest-free loan for financing qualified energy projects. Clean Renewable Energy Bonds For the 2007 round of awards, there were 786 applicants from 40 states seeking a total of $2.5 billion in bond authorization (three times what was available). 610 projects were approved including 78 private projects in 24 states ranged from $120,000 to $31 million. 25% of the applicants were in California (presumably high solar pv project count); other active states were New Mexico, Montana, Minnesota and Colorado. There were few applicants from the East and South other than Massachusetts. Entrepreneurial Approach Well run Digester an Environmental Bonanza Can Take Organic Wastes and Treat for Money CA – Food Wastes New England – Flammable Hazardous Petroleum / Waste Wastes Food and More Pluses – Tipping Fees – Can Greatly Increase Methane Production Power Payback Essex Junction VT Investor Partnering Digester Projects are Wanted Commodities by the Investment Community Shared-Savings – Open Book Approach ESCO’s Value of Carbon seen as ‘sure thing’ Private – Public Partnership can make project happen Summary Trend towards Increased Sludge Digestion in US and World Reverses Trends (EPA) of Previous 25 years Alternate Energy Market – Driven If you Have Methane – Easy Analysis to Develop If you are Planning Stages, my belief is that Switch to Digestion Will and Can Pay Expert-Driven Field Integrating Design, Construction and Financing QUESTIONS