Lab 4: Deformation due to Cyclic Loading Fu, Amy Scott, Shin Shan

advertisement

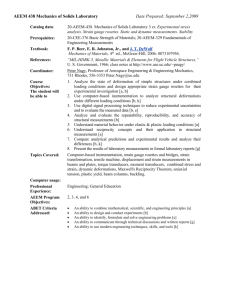

Lab 4: Deformation due to Cyclic Loading Fu, Amy Scott, Shin Shan, SiSi Son, Jennifer Wen, Alexander Date Submitted: March 24, 2011 Date Performed: March 17, 2011 Lab Section: 104 (Group 20) Lab GSI: Hua Xiang Abstract This lab studied the mechanical behavior of deformations due to cyclic loading. Samples of AISI 1045 steel were used in repetitive loading and unloading reversals at either constant strain or constant stress to observe the effects of cyclic hardening, plastic shakedown, ratcheting, and energy dissipated. The different values of strain and stress values were used to prompt different material responses. As a result of our experiment, we determined several properties of cycling loading. We observed that the greater the difference between the upper and lower loads, the greater the dissipated energy and the faster the fracture occurs. Also, cyclic loading with a greater strain energy density causes specimens to fracture after a fewer number of cycles. Lastly, in the strain rate dependence tests, it was found that an increase in strain amplitude results in an increase in dissipated energy, resulting in a smaller cycle life. 1. Introduction The yield strength of a material is important in safety considerations because it is the physical limit of the amount of stress a material can receive before failing. However, it is important to realize that material failure can occur even when the stresses involved are below the yield strength and ultimate tensile strength. Cyclic stresses and strains can cause microscopic structural damage that can progressively accumulate with loading (this phenomenon is known as fatigue), which can lead to the failure of the material [1]. The purpose of this lab is to observe the mechanical behavior of deformations due to cyclic loading. In the following experiments, the material properties of AISI 1045 specimens were qualitatively and quantitatively measured with six different cyclic loading tests. The first four tensile tests were straincontrolled tests, while the last two tensile tests were load-controlled. After all six tensile tests, stress-strain data was collected and graphed, and photographs of the samples were taken. Aside from the interesting fact that cyclic loading can cause material failure at stresses and strains below material limits, the purpose of this experiment is to demonstrate the different stress-strain responses as compared to that achieved under monotonic loading. While the Instron machine pulls on the ends of the samples, subjecting them to stresses and strains for a total of 25 cyclic loadings, the material may show four different stress-strain responses depending of the applied load and material limits: at loads below the elastic limit, the material response is purely elastic; if plastic deformation occurs initially, then is followed by an elastic steady-state response, elastic shakedown occurs; if the elastic shakedown limit is exceeded but the steady-state response is a closed cycle of plastic strain, plastic shakedown occurs; otherwise ratcheting occurs and cyclic loadings result in increasing plastic strain [2]. Because the material is deforming throughout the experiment, the values of stress/strain needed to maintain constant strain/stress varies as the number of loadings increases. As such, materials can be categorized based on their stress-strain responses: there is cyclic hardening if the stress increases with cycles of fixed strain, or cyclic softening if the stress decreases. Typically, most engineering materials exhibit rapid cyclic hardening or softening with initial deformation, but can reach an approximately stable configuration as the difference between cycles decreases with the number of cycles [3]. Although this lab only tests one type of material, the general behavior of AISI 1045 steel is representative of the effects of cyclic loading on elastic-plastic materials, with the difference being the relative magnitudes between stress and strain. Through this lab, students learn about another important mode of failure for materials, as well as how to interpret and present the resulting data. 2. Theory The mechanical behavior of AISI 1045 steel under cyclic loading is shown by subjecting the sample to repetitive uniaxial loading and unloading with the Instron machine. The objective of the lab is to correlate the cyclic loading to the hardening/softening response of the material. For the first four experiments, we used strain-controlled tests. For the last two, we used a loadcontrolled test. There are four different possible material responses: the first is purely elastic, where the load never meets the yield point; there is no plastic deformation and therefore, the graph looks like a straight line. The second is elastic shakedown, where the load produces yielding but only in the initial loading; then, because of elastic strain hardening and/or unloading hardening, the material demonstrates purely elastic behavior. The third and fourth tests show plastic shakedown and ratcheting, respectively. If the graph representing the material behavior extends above the elastic shakedown limit, then it becomes plastic shakedown, and if it extends above the plastic shakedown limit, then it becomes ratcheting. In either case, a hysteresis loop forms on the stress-strain graph and the loop represents the dissipation energy of that particular load cycle. For the tests performed, the engineering stress is given by [Equation 1], where P is the instantaneous force and A0 is the initial cross-sectional area. Engineering strain is given by [Equation 2], where l0 is the initial gauge length and l is the current gauge length. Since the previous two equations do not account for change in the cross-sectional area, the introduction of true strain or true stress is necessary. [Equation 3] is the equation of true stress, where A is the current cross-sectional area. By assuming that the volume is constant (i.e. A∙l = A0∙l0), the true strain can be found by using [Equation 4].The stress range, Δσ, is given by [Equation 5], where Δɛe is the change in elastic strain, and the strain range, Δɛ, is given by [Equation 6], where Δɛp is the change in plastic strain. The two ranges are used to calculate the area inside the hysteresis loops for plastic shakedown. Using the area inside the hysteresis loop of one cycle, the amount of dissipated energy can be determined using [Equation 7], where f1(ɛ) and f2(ɛ) are equations that can be found by putting the data through a graphing program. P l l l 0 l0 l0 AO [Equation 2] [Equation 1] l P P A ~ 0 (1 ) A A0 A l0 ˜ l l0 dl ln(1 ) l [Equation 4] [Equation 3] Δσ = E∙Δεe [Equation 5] Δε = Δεe + Δεp [Equation 6] [Table 1] Relevant equations. 3. Experimental Procedure Fatigue testing of AISI 1045 steel due to load/unload reversals was done on the Instron series 5500, with the maximum tensile load set equal to 80 kN. The Instron tensile tester was connected to a computer workstation and control panel. There were a total of six tests performed using this setup. The tests used 0.5 inch-wide sheet-type specimens with dimensions in accordance with the ASTM code A37005 [1]. The procedure for performing the tests can mostly be split into two parts, and done by two lab members. One member worked with the Instron machine, while the other worked at the computer workstation. The first portion was prior to the testing: one team member secured the sample into the clamps of the Instron tensile tester. After the specimen was secured, the same team member carefully mounted the extensometer at the center (with respect to the gauge length) of the fixed sample. Then, that team member rolled down the clear panel and the other team member started working. At the computer station, the extensometer had to be calibrated, the extension had to be zeroed, and the load had to be balanced before the test could be started. During the test, the team members watched the force-extension curve on the monitor of the computer station in case the force exceeded the set maximum limit. If that had happened, the team members would have to manually stop the test. The latter half of the procedure occurred after the test was done: the team member at the computer station saved the data and the team member at the Instron machine zeroed the load by adjusting the position knob on the control panel. Then the clear panel was rolled up, and the specimen was removed. If the specimen was fractured, the top half came out easily when the clamp was loosened. However, the bottom half needed to be gently hammered out after loosening. If the specimen was not fractured, the top clamp was loosened first, and drawn away from the specimen. The bottom half was unwound, and a gentle tap from a hammer was applied to pop the piece out. The group member on the machine then returned the clamps to their initial position by pressing the return button on the control panel. (1a) Strain Control 800 Engineering Stress (MPa) Engineering Stress (MPa) 4. Results 600 400 3.00% to 3.25% 6.75% to 6.85% 6.75% to 7.00% 6.75% to 7.15% 200 0 0 2 4 6 Engineering Strain (%) (1b) Load Control 600 500 400 300 200 40kN to 45kN 20kN to 45kN 100 0 8 0 2 Engineering Strain (%) 4 [Figure 1] Stress-strain curves for cyclic loading tests. (2b) 20 kN to 45 kN Load Control Engineering Stress (MPa) Engineering Stress (MPa) (2a) 40 kN to 45 kN Load Control 570 560 550 540 530 520 510 500 490 480 575 525 475 425 375 325 275 225 3.7 3.9 4.1 Engineering Strain (%) 3.7 3.9 4.1 Engineering Strain (%) [Figure 2] Stress-strain curves for load-controlled cyclic loading (Tests 5 and 6, respectively). Both tests show ratcheting, and Figure 2b (Test 6) shows hysteresis loops. (3b) Test 6. Strain Increase per Cycle (20 to 45 kN) Strain Increase (%) Strain Increase (%) (3a) Test 5. Strain Increase per Cycle (40 to 45kN) 0.09 0.08 0.07 0.06 Δεp = 0.043 0.05 0.04 0 Cycle 10 20 0.25 0.23 Δεp = 0.195 0.21 0.19 0 Cycle 10 20 [Figure 3] Strain increase per cycle in Tests 5 and 6. Test 6 shows a sharper decrease in this value. In Test 5, Δεp = 0.043, and in Test 6, Δεp = 0.195 because the plots approach these values asymptotically. (4b) 6.75% to 6.85% Strain Control 470 420 370 320 270 220 170 120 70 Engineering Stress (MPa) Engineering Stress (MPa) (4a) 3.00% to 3.25% Strain Control 570 520 470 420 370 2.98 3.08 3.18 3.28 6.74 Engineering Strain (%) (4c) 6.75% to 7.00% Strain Control 6.84 6.89 (4d) 6.75% to 7.15% Strain Control 700 600 600 550 500 Engineering Stress (MPa) Engineering Stress (MPa) 6.79 Engineering Strain (N) 450 400 350 300 250 200 500 400 300 200 100 0 150 6.7 6.8 6.9 7 7.1 Engineering Strain (%) -100 6.7 6.8 6.9 7 7.1 7.2 Engineering Strain (%) [Figure 4] Close-up of hysteresis loop development in Tests 1 through 4. Figure Test 1 (3a) Test 2 (3b) Test 3 (3c) Test 4 (3d) Material Response Plastic Shakedown Elastic Shakedown Plastic Shakedown Plastic Shakedown Energy Dissipated, Ed (N∙mm) 2426.5 659.92 (small) 1905 9160.3 [Table 2] Summary of material response and energy dissipated in Tests 1 through 4. All four tests showed hysteresis loop development, but Test 2 did so less than the others. All tests show convergence towards a steady-state hysteresis loop. The energy dissipated was calculated by averaging the area inside each hysteresis loop (resulting from each loading cycle) using a MATLAB function. 5. Discussion Tests 1 and 3 both had the same strain amplitude (εa) of 0.25%, but had different strain ranges and hence, different mean strains (εm). The AISI 1045 specimen used in Test 1 was expected to demonstrate elastic shakedown (ES) behavior [3], in which the curves for loading and unloading overlap and no energy is dissipated. However, our results showed that the specimen exhibited plastic shakedown (PS) behavior instead, in which there is a hysteresis curve – the area enclosed within this curve is the energy dissipated (Ed), per cycle, by the plastic deformation. A greater Ed indicates that there will be a smaller number of cycles (Nf) before fracture occurs. The discrepancy between our results and what was expected is most likely due to the natural variations in properties between specimens. The specimen for Test 3 exhibited PS behavior as expected [3]. Typically, an increase in εm should change the steady-state material response from ES to PS, but in our case, due to the odd sample, εm did not appear to have an impact on the material response. Tests 2, 3, and 4 began at the same minimum strain of 6.75%, but had different εa values (εa increased by 0.15% between each test). Test 2 had a significant amount of overlap between loading and unloading (i.e. the hysteresis loop was negligibly small); therefore, the specimen virtually displayed ES behavior. Test 3, as mentioned above, had PS behavior. Test 4 also demonstrated PS behavior, but had a larger hysteresis curve, implying that its Ed was greater. Therefore, it can be concluded that an increase in εa results in an increase in Ed and a smaller value of Nf,, and as a consequence, the material response changes from ES to low-energy PS to high-energy PS. Tests 5 and 6 were subjected to a load control with a maximum load of 45 kN for both, and a minimum of 40 kN and 20 kN, respectively. The specimens for both tests displayed ratcheting behavior, in which there was an accumulation of unidirectional plastic strain. The difference was that for Test 5, there were no hysteresis loops, whereas Test 6 had noticeable loops. Hence, the greater the difference between the upper and lower loads (i.e. the amplitude), the greater the dissipated energy and the faster the fracture occurs. In terms of the elastic-plastic deformation theory, the strain increment (Δεp) decreases for both specimens as the strain increases, suggesting that strain hardening has occurred; plastic deformations alter the microscopic structure of materials by breaking inter-atomic bonds and causing them to rearrange, thus becoming more brittle and more likely to fracture. This decrease in Δεp is much more pronounced in the case where the lower load is 20 kN, which means that the specimen for Test 6 will fracture more easily than the one for Test 5. This conclusion agrees with the theory that a cyclic loading with a greater strain energy density would cause the specimen to fracture after a fewer number of cycles. In practical engineering, ES is correlated with high-cycle fatigue, PS with low-cycle fatigue, and ratcheting with very low-cycle fatigue; fatigue is the phenomenon where a material suddenly fails even though the loads acting on it are less than its ultimate tensile strength (and sometimes the yield strength). This occurs because cyclic loading damages the material’s microstructure, causing infinitesimal cracks that accumulate up to a critical point at which sudden fracture occurs. 6. Conclusions The results of this lab clearly indicate that increasing the strain amplitude will lead to an increase in the amount of energy that is dissipated by the plastic deformation. Increased energy dissipation, in turn, will reduce the number of cycles that it will take to fracture the material. In addition, a sufficient increase in Ed will generally cause the material response to change from elastic shakedown to plastic shakedown. An increase in the mean strain is also supposed to have the same effect, but due to variations between samples, our results suggested that the mean strain will not much of an effect, as both Tests 1 and 3 displayed elastic shakedown behavior. Increasing the amplitude of the load (i.e. the difference between the upper and lower loads) will also cause more energy to be dissipated by the deformation; in this case, the loading was great enough to result in ratcheting behavior, and an increase of Ed means that the stressstrain curve for the ratcheting will have larger hysteresis loops. Furthermore, increasing Ed will cause the strain increment to decrease as the strain increases, meaning that there is a higher level of strain hardening, which reduces the number of cycles it takes to cause failure. All of these results are in compliance with the theory behind energy density and elastic-plastic deformation. Overall, an increase in the mean strain, and/or the strain amplitude, and/or the loading, will cause fracture to occur after a fewer number of cycles. 7. References 1. N. E. Dowling, Mechanical Behavior of Materials, 3rd edn (Upper Saddle River, NJ: Prentice Hall, 2007). 2. ASTM A 370-07: Standard Test Methods and Definitions for Mechanical Testing of Steel Products. 3. K. Komvopoulos, Mechanical Testing of Engineering Materials, 2nd edn (San Diego, CA: University Readers, 2011).