MINERAL RESOURCES

advertisement

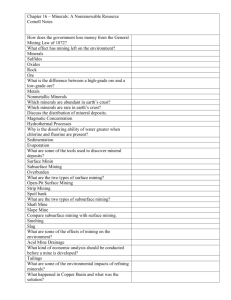

MINERAL RESOURCES External Earth Processes Erosion (wind, water ice, gravity) Mechanical weathering Frost wedging Chemical weathering (precipitation & Moisture) Biological weathering (root wedging, borrowing) Minerals and Rocks Mineral (diamond, quartz) Rock Types Igneous (granite, basalt) Sedimentary (limestone, sandstone) Metamorphic (marble, slate) Transport Erosion Deposition Shale, Sandstone, Limestone Rock Cycle Weathering Igneous Rock Granite, Pumice, Basalt Sedimentary Rock Heat, Pressure Heat, Metamorphic Rock Pressure Slate, Quartzite, Marble Magma (Molten Rock) Fig. 16-9 p. 339 Nonrenewable Resource • Resource that exists in a fixed amount in various places in the Earth’s crust and has the potential for renewal only by geological, physical and chemical processes taking place over hundreds of millions of years. • Mineral Resources – naturally occuring solid in or on the earth’s crust that can be extracted and processed into useful materials at an affordable cost. Nonrenewable Mineral Resources Metallic ores – (Fe, Cu, Al) Non-metallic – (salt, gypsum, clay, sand, PO4) Energy resources – (coal, radioactive isoptopes, oil, natural gas) Nonrenewable Mineral Resources: USGS Categories Identified – know location, quality and quantity Undiscovered inferred Reserves known location, affordable extraction Other -identified/ undiscovered but NOT reserved Finding Nonrenewable Mineral Resources Satellite and air imagery Radiation detectors Magnetometers Gravity differences Seismic surveys Chemical analyses Extracting Nonrenewable Mineral Resources: Open-pit (surface mining) Dredging (surface mining) Area strip (surface mining) Contour strip (surface mining) Room-and-pillar (subsurface mining) Longwall (subsurface mining) Open Pit Mining (surface) • Machines remove mineral resource. Dredging (surface) • Dig underwater mineral deposits Area Strip Mining (surface) • Strip mining in flat landscape areas. Contour Strip Mining (surface) • Creation of “terraces” along contour elevations where overburden is removed and a high wall is created which is very erodable. Mountaintop Removal • Dragline cuts the top of the mountain off and dumps it into the surrounding valley. Room and Pillar (subsurface) • This method creates shafts dug below the surface that are then blasted with dynamite to create tunnels. The ore/coal can then be hauled to the surface. Room & Pillar Method Room and pillar mining is commonly done in flat or gently dipping bedded ores. Pillars are left in place in a regular pattern while the rooms are mined out. In many room and pillar mines, the pillars are taken out, starting at the farthest point from the mine haulage exit, retreating, and letting the roof come down upon the floor. Room and pillar methods are well adapted to mechanization, and are used in deposits such as coal, potash, phosphate, salt, oil, shale, and bedded uranium ores. Longwall (subsurface) • Dig a narrow tunnel supported by removable pillars. The benefit is that no tunnels are left behind to collapse once abandoned. Subsurface vs. Surface Mining • Subsurface mining is less environmentally destructive than surface mining BUT Subsurface mining is more dangerous to workers. Walls collapse, explosions from gas, inhalation of mining dust leads to “black lung” U.S. 1872 Mining Law • Encourages mining in the USA for gold, silver, lead, copper, uranium, and hard rock minerals. • People OR Corporations can patent public land by: a. Declaring it has valuable minerals b. Spending $500 to improve land for mineral development c. Filing a claim for the land d. Pay US Government $2-5/acre! MINERALS NEVER NEED TO BE EXTRACTED Can sell land to extraction companies for millions of dollars (usually foreign companies) who pay no royalties to US Government. Colorado Case Study • Canadian Company bought a site for a few thousand dollars. • They spent 1 million dollars developing the site, removed 98 million dollars worth of gold. • Acid mine drainage leached into the Alamusa River. • Company declared bankruptcy and abandoned the site leaving the EPA Superfund to pay for clean up (= taxpayer money) • Costs = 40,000/day to contain toxic waste • Also contaminates irrigation water (no way to clean up) USA 1872 Mining Law Continued • If public land is designated as valuable wilderness area, the government can buy back the land (our tax $) at “market value”. • Any lands mined do not have to be reclaimed. They can be left in highly erodable states with leaching toxins into air, water, and soil. Mining Company Practices • 1. 2. 3. 4. 5. 6. Companies will usually: Mine land Abandon the land File for bankruptcy Leave taxpayers with cleanup bill (33-72 billion dollars per year! Superfund sites (Super funds that the EPA designates to be used for hazardous waste cleanup) If groundwater becomes contaminated, it can’t be cleaned up and there is no way of estimated the cost to humans! Should the mining law of 1972 be changed? • 1. 2. 3. 4. 5. 6. 7. Environmentalists propose amendments to the law: Lease land for 20 years instead of buying it. Conduct full NEPA Environmental Assessment of impacts before mining begins. Set strict standards for controlling pollution and protecting environment from toxins and erosion. Company should post environmental insurance bond to cover estimated environmental damage and clean up costs in the future. Companies should pay rent to cover costs for government monitoring of lands. 12.5% royalty should be paid to government on gross sales. Mining companies claim that charging royalties and forcing them to clean up their mess will not make it economically feasible to mine in USA anymore. This will lead to a decrease in jobs for Americans. Environmentalists claim mining companies will still make profits, just not as much! Make mining companies legally and financially responsible for clean up. Surface Mining Control and Reclamation Act Established 1977 Mine lands must be restored to pre-mining conditions Taxes on mining companies to restore pre-1977 sites Limited success Environmental Effects of Mining Mineral Resources Disruption of land surface Subsidence Erosion of solid mining waste Acid mine drainage Air pollution Storage and leakage of liquid mining waste Environmental Degradation From Exploration and Extraction • • • • • • • Scanning land surface Fires in coal mines cannot always be extinguished. Subsidence above subsurface mines. Mining spoils and heaps Erosion of tailings into waterways Mining dust (toxic) in air Acid mine drainage from rainwater into nearby streams and infiltration into groundwater. The most toxic are radioactive uranium, lead, arsenic, mercury and cadmium (heavy metals). • USA – over 12,000 miles of streams, 180,000 acres of reservoirs, and an unknown amount of groundwater have been contaminated. Environmental Degradation From Processing of Minerals • Processing includes transportation, purification, and manufacturing of minerals • Smelting impacts air, water, and soil “What goes up must come back down” Smelting desired ore Gange (waste) Beneficiation – separation of additional ore from gange Ore Tailings (toxic metals) Smelting Copper • Cu Sox soot (SO2) + As + Cd + Pb Scrubbers and electrostatic precipitators are expensive technology that help to remove the harmful substances before being released into the atmosphere. Environmental Degradation From End-Use • Transportation to user, final use, and discarding after use. (a) Fossil fuels are burned during transportation of end product. (b) Product must be discarded in: 1. landfill where metals corrode and pollute land and water. 2. Recycle and reuse (In USA, most goe to landfill, but recycling of solid waste is improving each year. Environmental Effects of Mining Mineral Resources Fig. 16-14 p. 344 More Environmental Impacts of Nonrenewable Mineral Resources Surface mining Subsurface mining Overburden Room and pillar Spoil Longwall Open-pit Dredging Strip mining Refer to Figs. 15-4 and 15-5, p. 341 and 342 Processing Mineral Resources Ore mineral Gangue Tailings Smelting Refer to Fig. 16-15 p. 344 Supplies of Non-Renewable Resources • Dependent on: (a) actual or potential supplies (b) rate of use Minerals become economically depleted when the cost of extraction is greater that the profit. What de we do? We have choices (a) refuse, reduce, reuse, recycle (b) find substitute Depletion of Mineral Resources Depletion Time – the time it takes to use up a certain proportion (80%) of the reserves of a mineral at a given rate. Common Projection Rate – “Reserve to Production Ratio” = the number of years that proven reserves of a particular non-renewable resource will last at a current production rate. Economics of Mineral Resources • Free Market when supply is greater than demand = cheap costs to consumers. Definition: a market in which supply and demand are unregulated except by the country's competition policy, and rights in physical and intellectual property are upheld. In a free market there are: (a)Fulfillment: the process of responding to customer inquiries, orders, or sales promotion offers. (b)Future: a contract to deliver a commodity at a future date. (c)Futures market: a market for buying and selling securities, commodities, or currencies that tend to fluctuate in price over a period of time. Why are items made of Zn, Pb, Hg, Fe, and Al so cheap, if their depletion times are nearing? • • 1. 2. 3. 4. Fe/Al – 100 years in world reserves. Hg/Zn/Pb – 20 years in world reserves. Subsidies – to promote economic growth and national security. Is there really a free market? Harmful environmental costs of mining and processing are not included in their market price. NO TRUE COSTING! Ore grades have been lowered. Example 1900 Cu penny – 5% by weight, now 0.5% by weight. Ask yourself…are reserve to ration production numbers real? As technology improves we learn more about where more minerals may be on Earth and don’t have to impart tremendous damage to landforms during exploration activities. Global Non-Fuel Minerals • Mostly in the USA, Canada, Australia, South Africa, and the Republics of the former Soviet Union. • Western Europe – depends mostly on minerals from Africa. • USA imports 24 of the 42 most important non-fuel minerals. • Concerns: manganese, cobalt, platinum, and chromium – USA has little or no reserves and we get them from unstable African nations. • USA uses these minerals for autos, airplanes, engines, satellites, and sophisticated weapons!