Presentation 3.2 - Food and Agriculture Organization of the United

advertisement

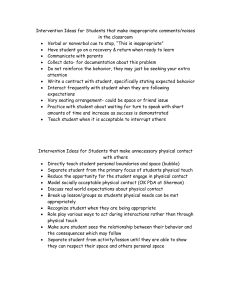

Presentation 3.2 Presentation 3.2 Product quality at harvesting Presentation 3.2 Presentation 3.2 Product quality after improper mechanical grading process. Presentation 3.2 • Product quality maintenance (reduce loses) • Generate product added value • Generate market opportunities Presentation 3.2 Product loses. (Quality decay/physical loses). High costs and low profits. Loss of market opportunities. Low competitiveness. Presentation 3.2 Key processes during the post-harvest- life : • • • • Respiration . Transpiration . Ethylene production. Maturity process. Presentation 3.2 Factors affecting the respiration rate of FFV: Internal: Type of tissue or organ: Leaves > fruits> roots. Product size: bigger size< respiration rate. Stages of development: young leaves >respiration. In fruits will depend on their classification as climacteric or nonclimacteric. Presentation 3.2 Presentation 3.2 Respiración Climatérica 180 160 140 120 100 80 60 40 20 0 Cherimoya Mango Prickly pear Tomate time 30 20 Strawberry Grape 10 Cherry Lemon 0 Time CLIMACTERIC NO-CLIMACTERIC Avocado Mango Guava Plantain Banana Papaya Apple Carambola Egg-Plant Lemon Orange Watermelon Pineapple Respiration rate Low Moderate High Very High Rep. Rhythm . Mg CO2/Kg./Hr 5 - 10 mg PRODUCT Sugar beet, garlic, onion, watermelon, citrus. 10 - 20 mg Cabbage, carrot, cucumber, mango, tomato. 20 - 40 mg Avocado, cauliflower, lettuce, strawberry. 40 - 60 mg Artichoke, broccoli, spinach, parsley, sweet Corn. PERISHABILITY POTENTIAL LIFE INDEX (WEEKS) Very high < 2 weeks High 2 - 4 weeks Moderate 4 - 8 weeks Low 8 - 16 weeks Very low > 16 weeks PRODUCTS broccoli, cauliflower, blackberry, strawberry avocado, pineapple, celery, tomato lemon, watermelon mango, potato, onion, apple, garlic, pear nuts, dried fruits. Factors affecting the respiration rates: External: mechanical damage and product’s sanitary condition. temperature. atmosphere composition (< Oxygen and CO2< respiration; > ethylene > respiration). physical barriers (waxes, plastic films, etc.) Presentation 3.2 • the temperature - affects the degree of response/ severity of mechanical damage. • Compromise natural barriers -increasing water loses and pathogenic infections. Impact Respiration Ethylene Time Presentation 3.2 Presentation 3.2 • At temperatures 30ºC above the optimum, the rate of 20ºC deterioration increases 2 to 3 fold for every 10ºC rise in 10ºC temperature. • High temperatureincreases the transpiration rate. Time Loss of water, as vapor, from the product’s area exposed to the air, throughout the cuticle, lenticels, stomas, etc. It depends on: Internal factors: species and variety. type of tissue. integrity and sanitary product condition. Presentation 3.2 External factors: Relative Humidity (<RH> transpiration). Temperature (> temperature> transpiration) Air movement (increase the transpiration rate). Altitude (higher altitude< transpiration). Physical barriers (avoid air contact with the product-reduce transpiration rate). Presentation 3.2 Climacteric fruits are sensitive to ethylene- produce larger quantities of ethylene in association with their ripening- (auto catalysis). No climacteric fruits produce very small quantities of ethylene. At high concentration produce degreening and increase the metabolism. Leafy vegetables are highly sensitive to Ethylene (withering and yellowing ) Presentation 3.2 Physiological process that occur at the cellular level. After finishing the anabolic process, a series of catalytic reactions start –degradation of: chlorophyll, aromas, organelles and finally causing cellular collapse/death. Post-harvest technology: to delay as long as possible, the tissue disintegration/senescence phase Presentation 3.2 STRAWBERRY –EXTERNAL COLOUR CHANGES. MANGO-INTERNAL COLOUR CHANGES • Loss of chlorophyll (undesirable in veg.) • Production of carotenoids and antocianines. • Starches conversion into sugars. • Changes in organic acids, proteins and fats. • Reduction in tannins and fungistatic compounds. 100% 100% 0% Unripe 0% Ripened Exterior Interior To reduce and delay the action of the internal factors that are responsible for product deterioration Presentation 3.2 Avoid the negative effect of external factors Temperature control. • Product protection from sun heat (full sunlight) after harvesting. • Pre-cooling treatments to remove field heat. • Refrigeration. • Maintaining the cold chain. Presentation 3.2 • Key factor affecting product deterioration rate. • is the most effective tool for extending the shelf life of fresh horticultural commodities. • Key effect on spores germination and pathogenic growth. Presentation 3.2 Effect of temperature on deterioration rate of a non-chilling sensitive commodity Temperature (°C) Assumed Q10* 0 10 3 20 2.5 30 2 40 1.5 Source: Kader & Rolle (2003) Presentation 3.2 Relative Relative post- Loss per velocity of harvest life day (%) deterioration 1 100 1 3 33 3 7.5 13 8 15 7 14 22.5 4 25 Temperatures above or below the optimal range, can cause product deterioration due to: • Freezing. • Chilling injury. • Heat injury. Presentation 3.2 • Freezing point of perishable commodities is relatively high (ranging from -0.3 ºC y -0.5 º C). • Freezing produces an immediate collapse of tissues and total loss of cellular integrity. • A result of inadequate design of refrigerator or failure of thermostats. Presentation 3.2 Chilling Injury: Some commodities (mainly tropical and subtropical) respond unfavorably to storage at low temperatures well above their freezing points, temperatures called the chilling threshold temperature or lowest safe temperature. Presentation 3.2 Classification of chilling-sensitive fruits and vegetables according to their lowest safe temperature for transport and storage Lowest safe temperature Commodities (°C) 3 Asparagus, cranberry, jujube 4 Cantaloupe, certain apple cultivars (such as McIntosh and Yellow Newton), certain avocado cultivars (such as Booth and Lula), lychee, potato, tamarillo 5 Cactus pear, cowpeas, durian, feijoa, guava, kumquat, lima bean, longan, mandarin, orange, pepino 7 Certain avocado cultivars (such as Fuerte and Hass), chayote, okra, olive, pepper, pineapple, pomegranate, snap bean 10 Carambola, cucumber, eggplant, grapefruit, lime, mango (ripe), melons (casaba, crenshaw, honeydew, persian), papaya, passion fruit, plantain, rambutan, squash (soft rind), taro, tomato (ripe), watermelon 13 Banana, breadfruit, cherimoya, ginger, jackfruits, jicama, lemon, mango (mature-green), mangosteen, pumpkin and hard-rind squash, sapotes, sweet potato, tomato (maturegreen), yam Source: Kader & Rolle (2003) Presentation 3.2 Heat injury: Direct sources of heat can rapidly heat tissues to above the thermal death point of their cells, leading to localized bleaching or necrosis or general collapse. Presentation 3.2 Objective: to remove the field heat. Movement of the caloric energy from the product to the cooling substance. Presentation 3.2 Comparison among cooling methods Cooling method Cooling times (h) 0.1-0.3 Water contact with the product yes Product moisture loss (%) 0-0.5 Capital cost high 0.1-1.0 0.3-2.0 ForcedRoom air 1.0-10.0 20-100 yes no no 0-0.5 low 2.0-4.0 0.1-2.0 medium low Energy efficiency low Source: Kader & Rolle (2003) high Variable Presentation 3.2 Ice Hydro Vacuum high no low 0.1-2.0 low low • Commercial cooling reaches up to 7/8 the final temperature. • First hours are crucial. • Additive effect of low temperatures. Time Presentation 3.2 Cooling rooms and refrigerated vehicles…. • • • • well designed and adequately equipped. resistant floors. perfectly insulated. with adequate and well-positioned doors for loading and unloading. • allow effective distribution of refrigerated air. • allow monitoring and temperature control. Presentation 3.2 Presentation 3.2 Presentation 3.2 • refrigerated coils surfaces designed to adequately minimize differences between the coil and air temperatures. • proper air spaces between pallets and room walls to ensure proper air circulation. • monitoring temperature (product rather than air temperature). Presentation 3.2 • transit vehicles must be cooled before loading the commodity. • avoid delays. • when mixing several products: product’s ethylene and chilling injury sensibility must be considered. • appropriate packing (air circulation and reducing mechanical damage) Presentation 3.2 Presentation 3.2 Relative humidity management. Is the moisture content (as water vapor) of the atmosphere, expressed as a percentage of the amount of moisture that can be retained by the atmosphere at a given temperature and pressure without condensation. RH can influence water loss, decay development, incidence of physiological disorders, and uniformity of fruit ripening. Presentation 3.2 • Fruits: 85-95% of RH. • Dry products: onion and pumpkin. 70-75% de RH. • Root vegetables: carrot, radish. 95-100% RH. Presentation 3.2 • Adding moisture (sprays, steam) • Regulating air movement and ventilation in relation to the produce load in the cold storage room. • Maintaining temperature of the refrigeration coils within about 1ºC of the air temperature. • Providing moisture barriers that insulate walls of storage room and transit vehicles. • Adding polyethylene liners in containers and using perforated polymeric films for packaging. Presentation 3.2 • • • • • Curing. Waxes and others surface coatings . Polymeric films for packing. Avoiding physical injuries. Adding water to those commodities that tolerate misting with water. Presentation 3.2 Wax layer restricts the gases interchange. Air in the internal Cavity • Wetting floors in storage rooms. • Adding crushed ice in shipping containers. • Sprinkling produce with sanitized, clean water during retail marketing of the product. Presentation 3.2 • avoiding sources of ethylene close to the product storage areas. • applications of 1-Methylcyclopropene (1MCP)- ethylene action inhibitor, commercially approved on July 2002 in apples, apricots, avocados, kiwifruit, mangoes, nectarine, papayas, peaches, pears, persimmons, plums, and tomatoes. Presentation 3.2 • Air ventilation of storage rooms. • Avoid mixing ethylene sensitive products with those non sensitive to ethylene, during storage and transport. Presentation 3.2 • Curing. • Heat treatments i.e.. dipping mangoes, 5 minutes to 50ºC water to reduce anthracnose development). • Post-harvest pesticides (i.e.. imazalil, thiabendazole). • Biological control agents, (i.e.. Bio-save-pseudomonas syringae y Aspire-Candida oleophila) in citrus fruits. • Growth Regulators as Gibberellic acid to delay senescence in citrus fruits. • 15-20% of CO2 in the air or 5% O2 in strawberries, pomegranates, figs, etc. • SO2 fumigation (100 ppm/1 hour) in grapes. Presentation 3.2 • Irradiation. • Quarantine treatments: – Chemical: methyl bromide, phosphine, hydrogen cyanide) – Cold treatments (Low temperatures) – Heat treatments – Combination of the previous. Presentation 3.2 Irradiation. • Dose varies in accordance with the species and its stage of development. • Doses of 250 Gy has been approved for: lychees, mangoes and papayas in USA for control of fruit fly. • At doses above 250 Gy and up to1000 Gy some commodities could present damages. . Presentation 3.2 Modified and controlled atmosphere storage Presentation 3.2 Classification of horticultural crops according to their controlled atmosphere storage potential at optimum temperatures and relative humidifies Range of storage Commodity duration (months) More than 12 Almond, Brazil nut, cashew, filbert, macadamia, pecan, pistachio, walnut, dried fruits and vegetables 6-12 Some cultivars of apples and European pears 3-6 Cabbage, Chinese cabbage, kiwifruit, persimmon, pomegranate, some cultivars of Asian pears Avocado, banana, cherry, grape (no SO2), mango, olive, onion (sweet cultivars), some cultivars of nectarine, peach and plum, tomato (mature-green) Asparagus, broccoli, cane berries, fig, lettuce, muskmelons, papaya, pineapple, strawberry, sweet corn; fresh-cut fruits and vegetables; some cut flowers 1-3 <1 Presentation 3.2 21% O2 O2 0.035% CO2 • Modify the concentration CO2 O2 CO2 • • • • of gases in the produce packing. Reduce respiration rate. Reduce ethylene action. Delay ripening & senescence. Increase product’s shelf life. Apples, as any living entities..breath Cold room 0ºC 2% O2 1% CO2 21% Oxigene 0.35% CO2 Filters Innovations: • Creation of nitrogen-on demand, using systems of Membrane systems or sieve beds. • Use of low oxygen concentrations (0.7 a 1.5%) and monitoring of such concentrations. • Ethylene free CA. • Programmed atmosphere. • Dynamic atmospheres- O2 y CO2 are modified through monitoring of produce quality attributes such as: ethanol concentration and chlorophyll fluorescence. Presentation 3.2 • Banana can be harvested at a later stage. • In avocados CA allows the use of lower temperatures than the conventional ones and reduces chilling injury. • In combination with temperature control, CA is used as quarantine treatment for the control of several insects. Presentation 3.2 • Use of MAP during packing is highly increasing. • Usually designed to maintain 2% - 5% of O2 and 8% - 12% of CO2, extend shelf life of fresh-cut fruits and vegetables. Presentation 3.2 Presentation 3.2 Apples treated with TBZ Polymeric filmperforated one Plastic or cardboard box Storage temperature-0.5oC • CA is used for transporting and storage of apples, pears, less used in kiwifruits, avocados, nuts, dry fruits and persimmon. • MA- for long distance transport is used in mangoes, apples, bananas, avocados, plums ,strawberries, blackberries, peaches, figs, nectarines. Presentation 3.2 Genetic factors, production of hybrids and varieties with…. • High contents of carotenes and Vitamin A (tomatoes, onions and carrots). • Long post-harvest life (tomatoes and onions). • High content of sugars (melon). • High content of ascorbic acid (pineapple). • In the future…Biotechnology will perhaps allow the introduction of resistance to physiological disorders and/or pathogens associated to quality decay. Presentation 3.2 Climatic conditions: • Temperature and light intensity can influence the content of ascorbic acid, carotenes, riboflavin, thiamine and flavonoids. • Rainfall affects the water supply and the susceptibility of plant organs to mechanical damage and decay. Presentation 3.2 Cultural practices: • Nutritional conditions: Calcium related with long postharvest life; high Nitrogen related with shorter postharvest life due to high susceptibility to mechanical damage, physiological disorders and decay. • Several physiological disorders are associated with nutritional deficiencies. • Water stress (from severe to moderate) is related with irregular ripening, reduced fruit size, increase Total Solid Soluble contents and acidity. • Water excess increases the susceptibility to physical damage in some products. Presentation 3.2 Primary damages…perceptible, what is easily identified by the consumer. • Biological: pest and diseases. • Chemical: visible external contamination with pesticides and chemical products; toxics and unpleasant flavors produced by pathogens, etc. • Mechanical: injures, cuts, bruises, grazes, drops, scrapings, shatters during harvesting, etc. • Physical: heating, freeze, freezing, water loss. • Physiological: sprouting, rooting, senescence, and changes caused by transpiration and respiration. Presentation 3.2 Primary damages are the result of inappropriate technologies and handling during the post-harvest chain: • inappropriate process of drying. • inappropriate Infrastructure for produce packaging and storage. • improper transport conditions. • lack of planning (i.e.. harvesting). • delays, improper conditions during distribution and marketing. Presentation 3.2 • during periods of oversupply-poor handling increase. • poor or inappropriate harvesting techniques. • poor produce handling. • damages originated during handling and transport. • delays during the distribution process. • loses of weight and water. Presentation 3.2 Harvesting Reception Other treatments Packing and packaging Presentation 3.2 Pre-cooling Selection, cleaning and disinfection Grading Drying Storage Transport Harvesting Associated hazards • inappropriate maturity at harvest (over ripening increases sensitivity to quality decay ; immature fruits market rejection). • inappropriate harvest technique (mechanical damages-physical injuries). • climatic conditions at harvesting (free water, exposition of product to direct sun light ) • harvesting wet products (increase sensitivity to quality decay) • inappropriate harvesting recipes/containers ( physical injuries). Presentation 3.2 Recommendations • training personnel on optimum maturity indices. • Application of appropriate maturity indices based on: external quality color, consistence, phenological stage, etc. • Harvesting time: early in the morning or late in the afternoon in order to minimize the sun effect. • Optimizing harvesting recipes/containers (size, materials, height, number of produce layers, conditions, etc. ) • protection of product of direct sun intensity. Presentation 3.2 Produce reception Associated hazards • uncovered areas (direct exposition of products to sun light and adverse climatic conditions) • inappropriate handling of the product during loading and unloading. • inappropriate product heaping (mechanical damages). • delays in the operations (if conditions are inappropriate they can generate increasing product temperature and quality decay) • lack of planning during harvesting (increase delays in the operations). • no methods applied to remove field heat or use of inappropriate ones. Presentation 3.2 Presentation 3.2 Pre-cooling Possible Hazards associated Definir actores/roles/ Expectativas. If the methods of pre-cooling are inappropriate, they can: • produce dehydration of the product (i.e.. high speed of cooling air) • tissue damage –i.e. as result of inappropriate packing -product contact with ice. • produce quality decay caused by sensitivity of the product to water exposition. • accelerate quality decay by accumulation of water in some areas of the product (between leaves and calyx) Presentation 3.2 Cleaning and disinfection Definir actores/roles/ Expectativas. Objective: Removing impurities from the product. Definir actores/roles/ Expectativas. Washing methods: Web methods: • Immersion (product floating). • Spraying . Dried methods: • Brushing. • Inhalation/aspirate. Presentation 3.2 Cleaning and disinfection Definir actores/roles/ Expectativas. Definir actores/roles/ Expectativas. Possible Hazards associated • product water sensitivity. • poor water quality. • mechanical damage (inappropriate conditions of brushes, etc). • water accumulation in the product can cause product quality decay. Presentation 3.2 Grading Associated Hazards Mechanical damages by vibration, impact/hitting, compression, etc. caused either by poor handling or inappropriate equipment maintenance and design. Grading methods: by size, weight, color, etc. Presentation 3.2 Packing and packaging Associated Hazards • poor packing design (reduces efficiency and increases the risk of mechanical and biological hazards). • improper packing (lack of ventilation, low material resistance, sharp and wrinkled surfaces, etc.). • Over packing (many product layers). Definir actores/roles/ Expectativas. Presentation 3.2 Packing and packaging Associated Hazards • Inappropriate pile up during packing. • packing products with different degree of maturity. • mechanical damages caused by personnel or improper design of mechanical grading machines. • Problems regarding over-handling of products and inappropriate process flows during post-harvest handling. Definir actores/roles/ Expectativas. Presentation 3.2 Storage Associated Hazards: mechanical, physical, biological damages. • Inappropriate design of cooling rooms. • Poor or lack of equipment maintenance and cleaning programmes. • Lack of control of temperature and Relative Humidity conditions. • Lack of control on personnel entrance to the cooling rooms. • Poor or lack of cooling rooms cleaning programmes. • Inappropriate distribution/location of the product inside the cooling room (reducing air circulation). Presentation 3.2 Transport Associated hazards: chemical, biological, mechanical damages. • Bad conditions of the vehicles tents/covers. • Poor cushioning systems of the vehicles. • Inappropriate systems of loading and unloading. • Uncovered vehicles, expose the product to the negative effect of the environmental conditions. • poor control of temperature and relative humidity in the refrigerated transport systems. • Inappropriate systems of packing (p.e. in bulk). Presentation 3.2 Definir actores/roles/ Expectativas. INNOVATIONS IN THE TRANSPORT Presentation 3.2 Definir actores/roles/ Expectativas. Loading and unloading systems efficiency Presentation 3.2 Efficiency of the loading and unloading systems Presentation 3.2 Other Postharvest treatments Associated hazards: increase Definir actores/roles/ product’s susceptibility to Expectativas. biological, mechanical damages and quality decay. • Improper handling during treatment application. • Inappropriate application of the treatments (p.e. temperatures above or below the optimum recommended). • Improper RH conditions. • Poor equipment maintenance and cleaning. • Doses above the recommended ones (i.e.. irradiation dosages). Presentation 3.2 • the selection of “the best technologies” to be applied, among a range of available postharvest technologies, should take into account: the product characteristics, the market distance and requirements, and the social and economical conditions of the actors involved. Presentation 3.2 To protect the product from direct sun light. Quick transport to the packaging. Minimize delays before pre-cooling. Uniform product’s cooling. Store the product at optimum temperature conditions . Practice first in first out rotation. Ship to market as soon as possible. Presentation 3.2 Use refrigerated loading area. Cool truck before loading. Load pallets towards the center of the truck. Avoid delays during transport. Monitor product temperature during transport. • There is not a direct relation between a given post-harvest technology efficiency and its cost. Expensive equipment does not always imply high efficiency, and even the best equipment, without proper management may have little utility and poor results. Effective training and supervision of personnel must be an integral part of quality and safety assurance programs. Presentation 3.2 Proper product handling during the post-harvest Chain relies in understanding the factors that affect the quality and safety of the product, and the different mechanisms to minimize their impact. Simple handling practices can have important impact on product quality and safety maintenance. Proper harvesting time, avoid direct sun light, proper handling, proper ventilation, etc. Presentation 3.2 Product quality maintenance and enhancing implies: • To identify the problems (main causes) and their magnitude (quality and physical loses). Also to identify the opportunities associated to the post-harvest technologies. • Search the available solutions to the problems identified, or mechanisms to take advantage of the opportunities. (training, application of available technologies, adjustment and validation of technologies if needed, practical research if need). • To evaluate the impact of small changes during the post-harvest chain. • To train the personnel involved in implementing the changes. • To identify the problems needing practical research in order to identify possible solutions. Presentation 3.2 FOOD AND AGRICULTURE ORGANIZATION OF THE UNITED NATIONS (FAO) Food Quality and Standards Service (ESNS) Food and Nutrition Division Viale delle Terme di Caracalla 00100 Rome, Italy. E-mail: food-quality@fao.org Tel.: +39 06 57053308 Fax.: +39 06 570 54593/53152 http://www.fao.org/ Photographic Material : Fernando Maul. Archives FAO. Presentation 3.2